Control system and control method of movement of glass cleaning robot at right angle area

A glass-wiping robot and control system technology, applied in two-dimensional position/channel control and other directions, can solve problems such as inconvenient operation and complex walking trajectory, and achieve the effects of convenient operation, improved cleaning efficiency and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

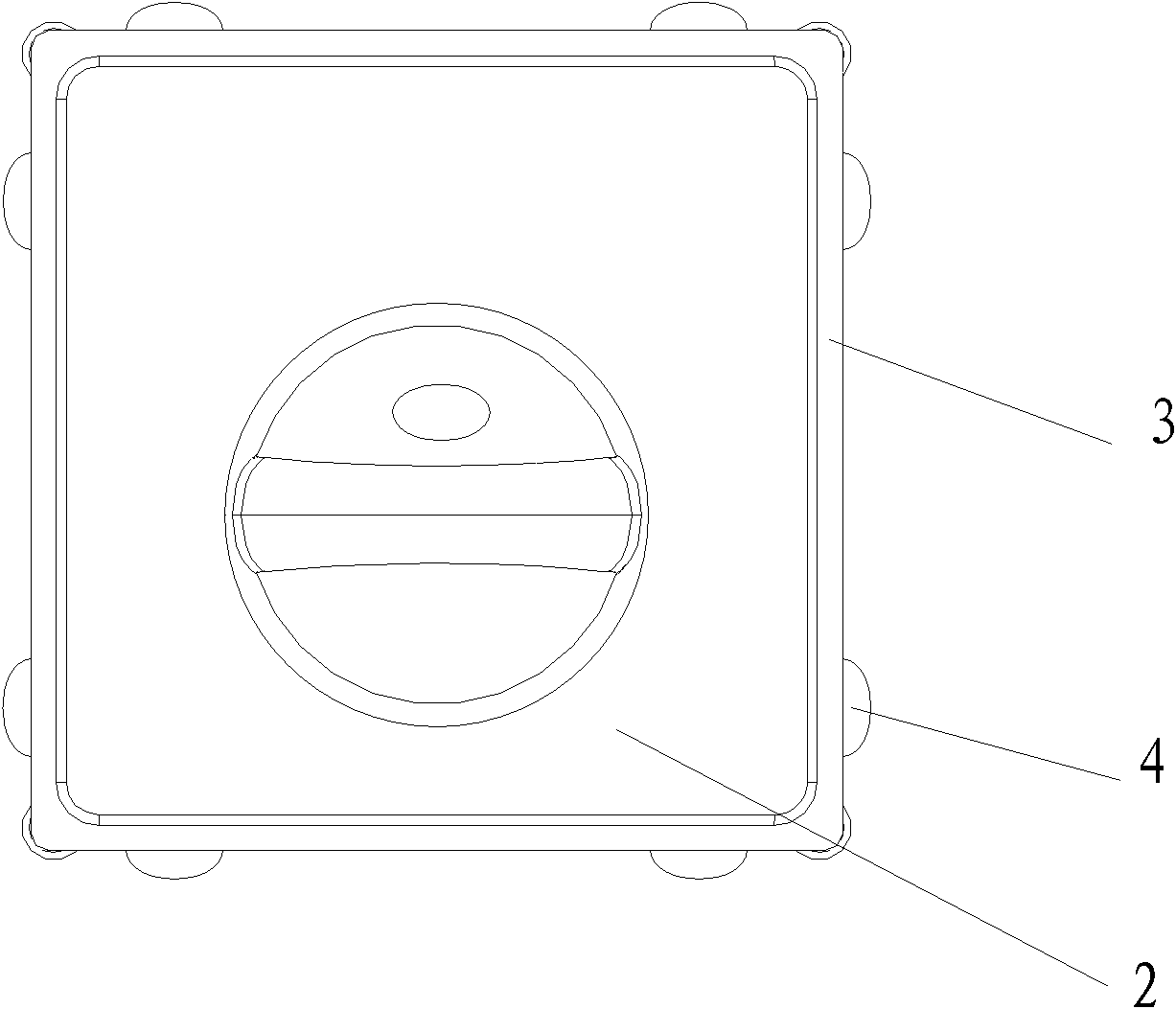

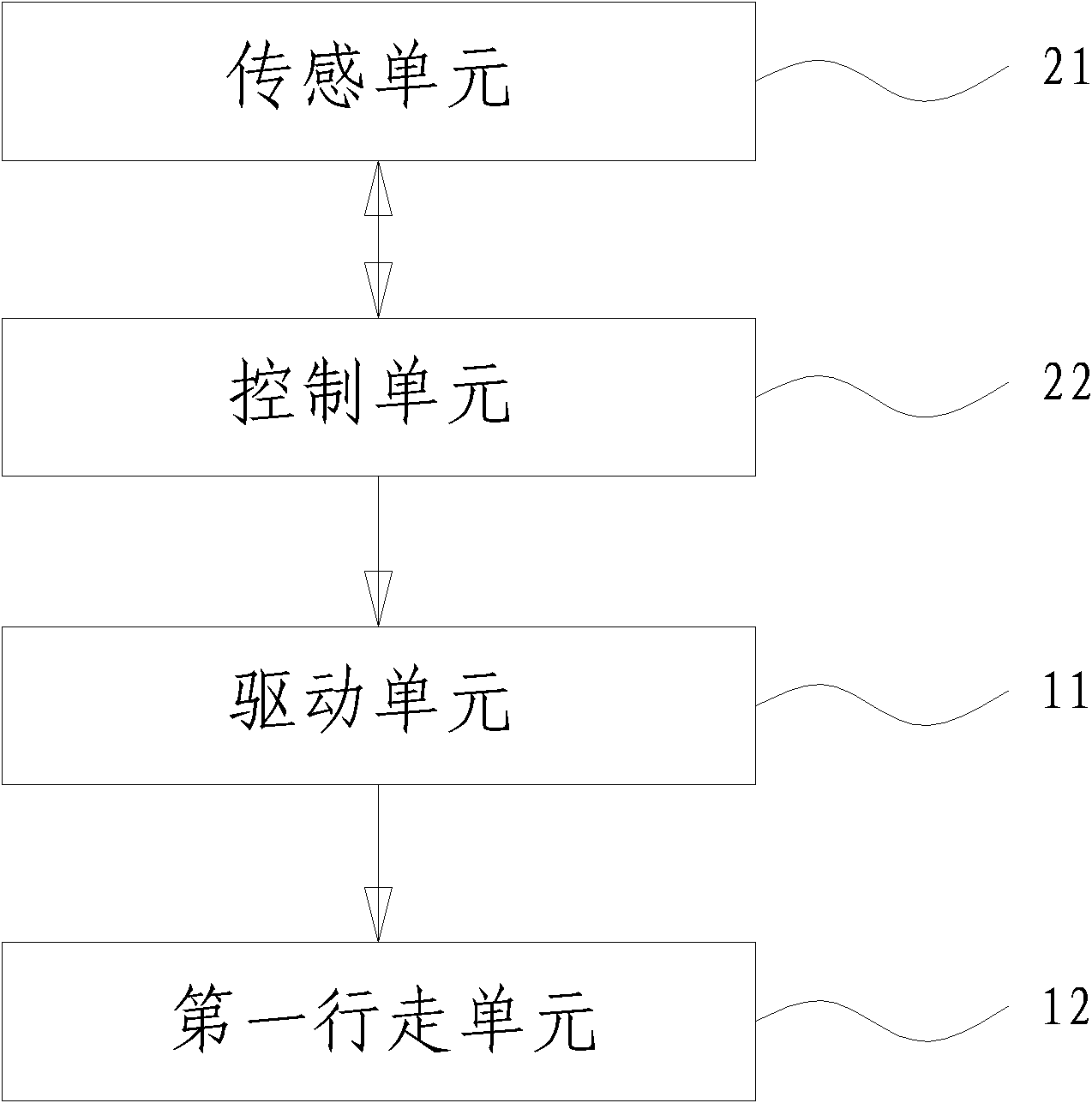

[0042] figure 2It is a schematic diagram of the principle of the right-angle area cleaning control system of the glass-wiping robot of the present invention. The glass-wiping robot of the present invention includes a driving unit 11 and a first walking unit 12 , and the right-angle area cleaning control system includes a sensing unit 21 and a control unit 22 . The control unit 22 is connected to the sensing unit 21 and the driving unit 11 respectively, and controls the driving unit 11 . In order to ensure smooth walking of the glass-wiping robot, the first walking unit 12 includes walking wheels arranged on the left and right sides of the lower surface of the glass-wiping robot body.

[0043] During the process of the glass-wiping robot walking in the right-angle area, the control unit 22 judges that the glass-wiping robot 1 is in a right-angle area; the glass-wiping robot also includes a state detection part, which is connected to the control unit 22, and the control unit ...

Embodiment 2

[0058] The sensors in the first sensor subunit 210 and the second sensor subunit 211, in addition to the contact sensor as described in Embodiment 1, can also use non-contact sensors, such as: infrared sensors or ultrasonic sensors sensor.

[0059] The difference between the glass-wiping robot 1 in this embodiment and the glass-wiping robot 1 in Embodiment 1 is that the sensors used in the first sensor subunit 210 and the second sensor subunit 211 in the sensing unit 21 are Non-contact sensor. Since the detection distance of the non-contact sensor has a certain range, obstacles within its detection range can be detected. If the detection distance is too large, when the distance between the glass cleaning robot 1 and the glass frame is still relatively large, it can The signal is detected, obviously the error is too large. There are two solutions to this problem. The first one is to select a non-contact sensor with a small detection distance, and within its detection distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com