Online anti-icing and de-icing control system of alternating current electrified railway catenary

An electrified railway and catenary technology, applied in the direction of AC network voltage adjustment, electrical components, overhead lines, etc., can solve the problems affecting the normal operation of the traction power supply system, unable to prevent ice and melt ice, etc., achieve low cost, reduce capacity and cost, the effect of increasing the terminal voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

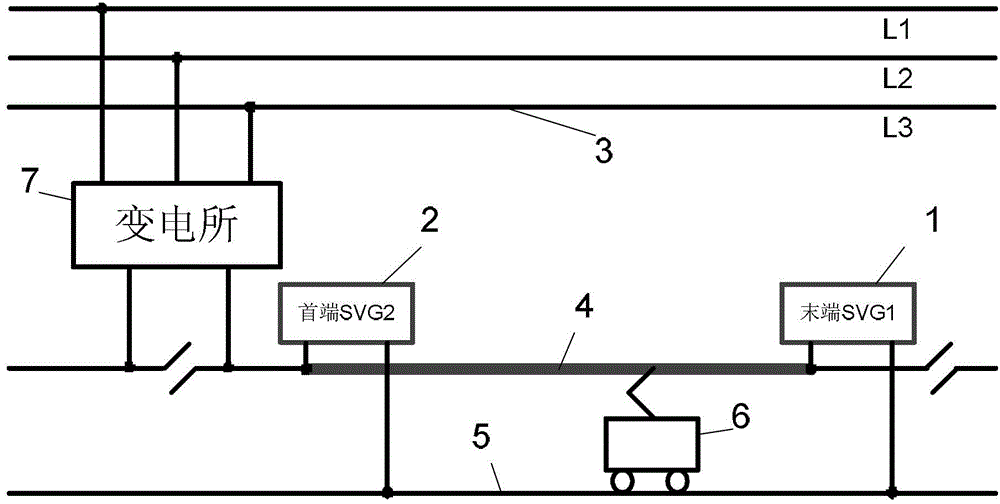

[0034] figure 1 It is shown that a specific implementation of the present invention is: an on-line anti-icing and melting system for an AC electrified railway traction network, including an anti-icing or melting current generating device SVG1 (1) at the end of the power supply arm and a current at the head end of the power supply arm Compensation device SVG2(2), of which:

[0035] The power supply arm end device SVG1 (1) is connected with the end of the traction net (4) and the steel rail (5), and generates anti-icing or melting current under the control of the control device.

[0036] The head end device SVG2 (2) of the power supply arm is connected with the head end of the traction net (4) and the steel rail (5), and under the control of the control device, it compensates for the anti-icing or melting current of the end SVG1 and the non-freezing current generated by the locomotive (6). Work current. The end melting current generating device SVG1 (1) and the head melting current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com