High voltage cable deicing device

A technology of high-voltage cables and deicing vehicles, which is applied in the installation of cables, electrical components, overhead installations, etc. It can solve the problems of cable power failure and affecting the power supply of the power system, and achieve the effect of realizing safe operation and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

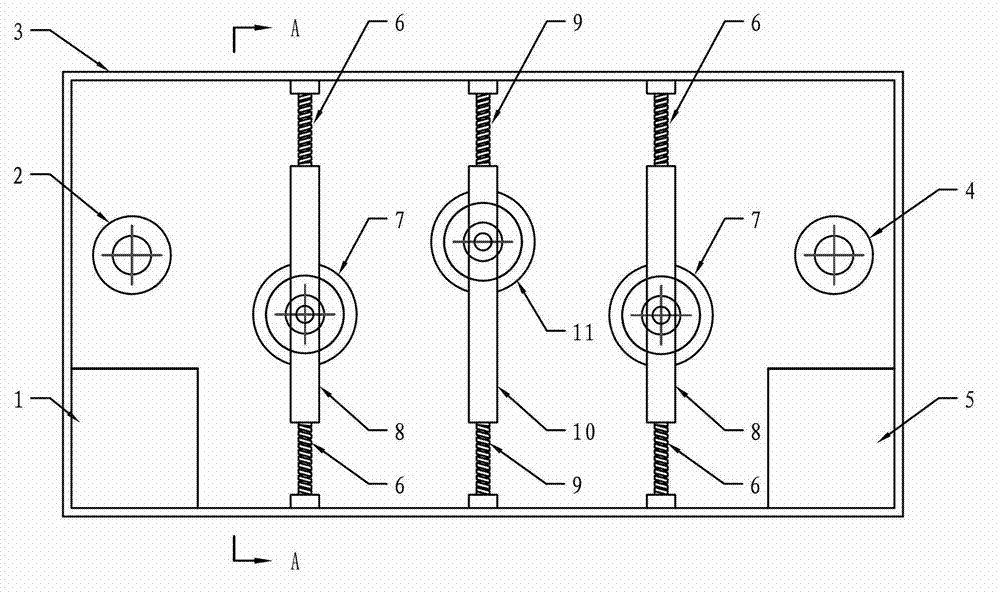

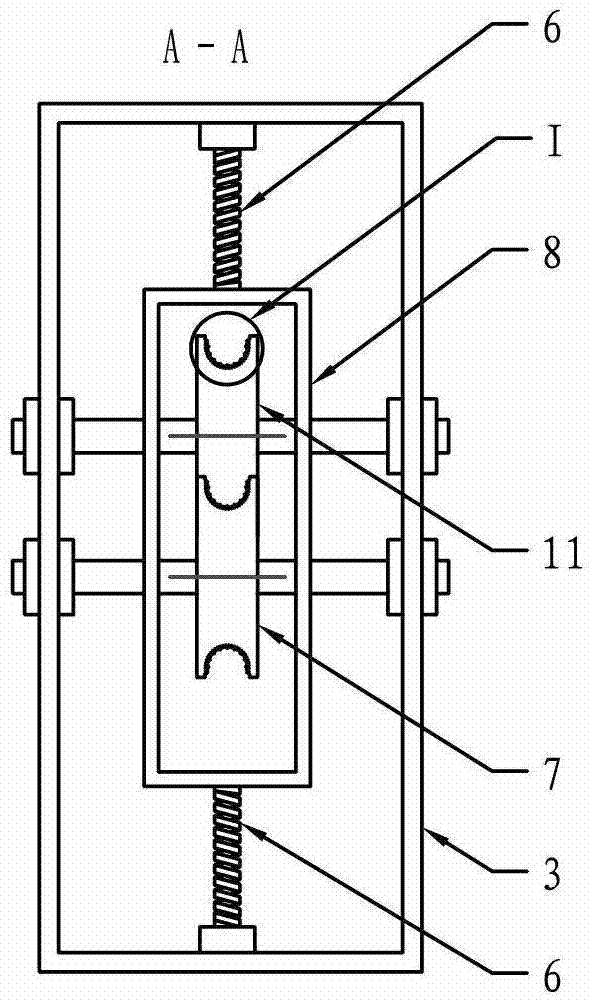

[0024] Specific Embodiment 1: The high-voltage cable deicing device described in this embodiment includes a deicing vehicle and a remote control, and the deicing vehicle includes a frame 3, an electric control box 1, a counterweight box 5, driving wheels 2, and a driven walking wheel. 4 and 3 deicing units, the driving wheel 2 and the driven wheel 4 are located at the same level and fixed on the front and rear of the frame 3 respectively, and the electric control box 1 and the counterweight box 5 are symmetrically arranged on the At the front and rear ends of the inner bottom of the frame 3, a counterweight is arranged in the counterweight box 5 so that the weight of the counterweight box 5 is the same as that of the electric control box 1, and the three deicing units are equally spaced between the active road wheel 2 and the secondary Between the moving wheels 4, the three deicing units include a pressing wheel unit and two lifting units, and the one pressing wheel unit is loc...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment is a further limitation of the high-voltage cable deicing device described in Embodiment 1. The rims of the driving wheel 2 and the driven wheel 4 described in this embodiment have grooves , for embedding high voltage cables.

[0031] The rims of the two road wheels in this embodiment are similar to the edges of train wheels, and this structure can make the two road wheels hang on the high-voltage cable stably and run smoothly.

specific Embodiment approach 3

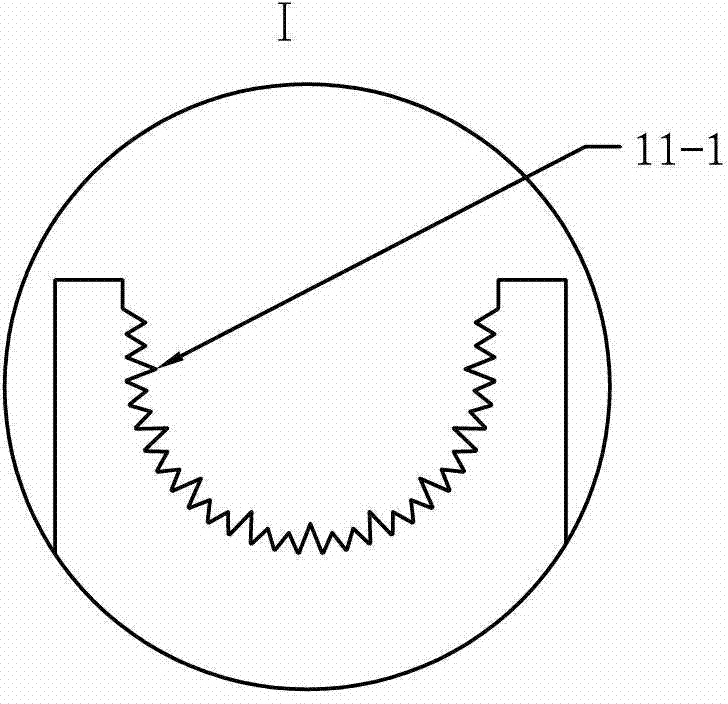

[0032]Embodiment 3: This embodiment is a further limitation to the high-voltage cable deicing device described in Embodiment 1 or Embodiment 2. The edge of the pressure roller 11 described in this embodiment has a groove, and the groove For embedding high voltage cables.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com