Shaft power generator based on axial flexural vibration of piezoelectric vibrator of cantilever beam

A piezoelectric vibrator, bending vibration technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., to achieve strong power generation capacity, improve reliability, and strong speed adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

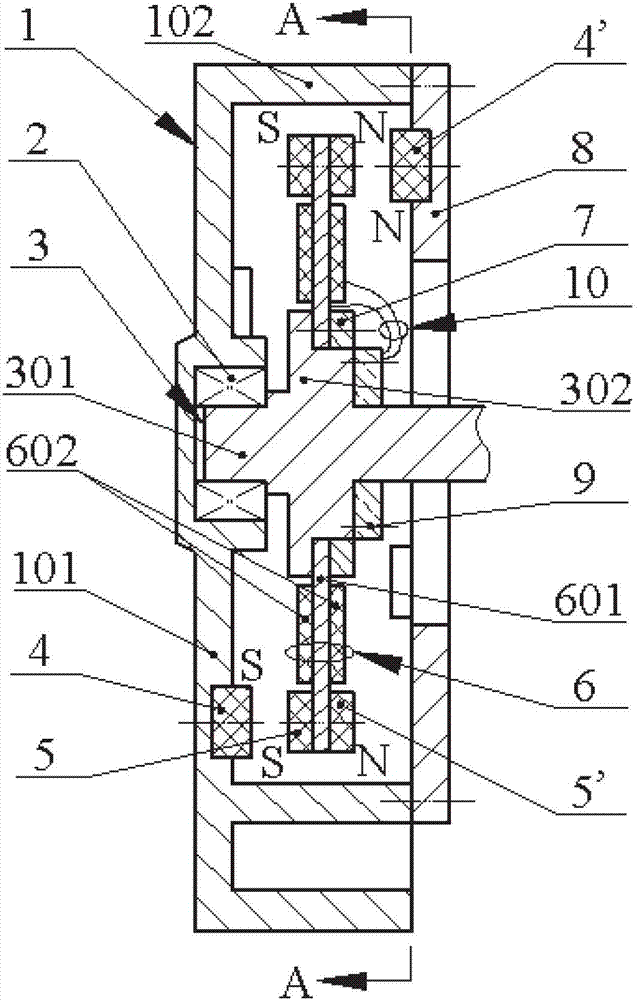

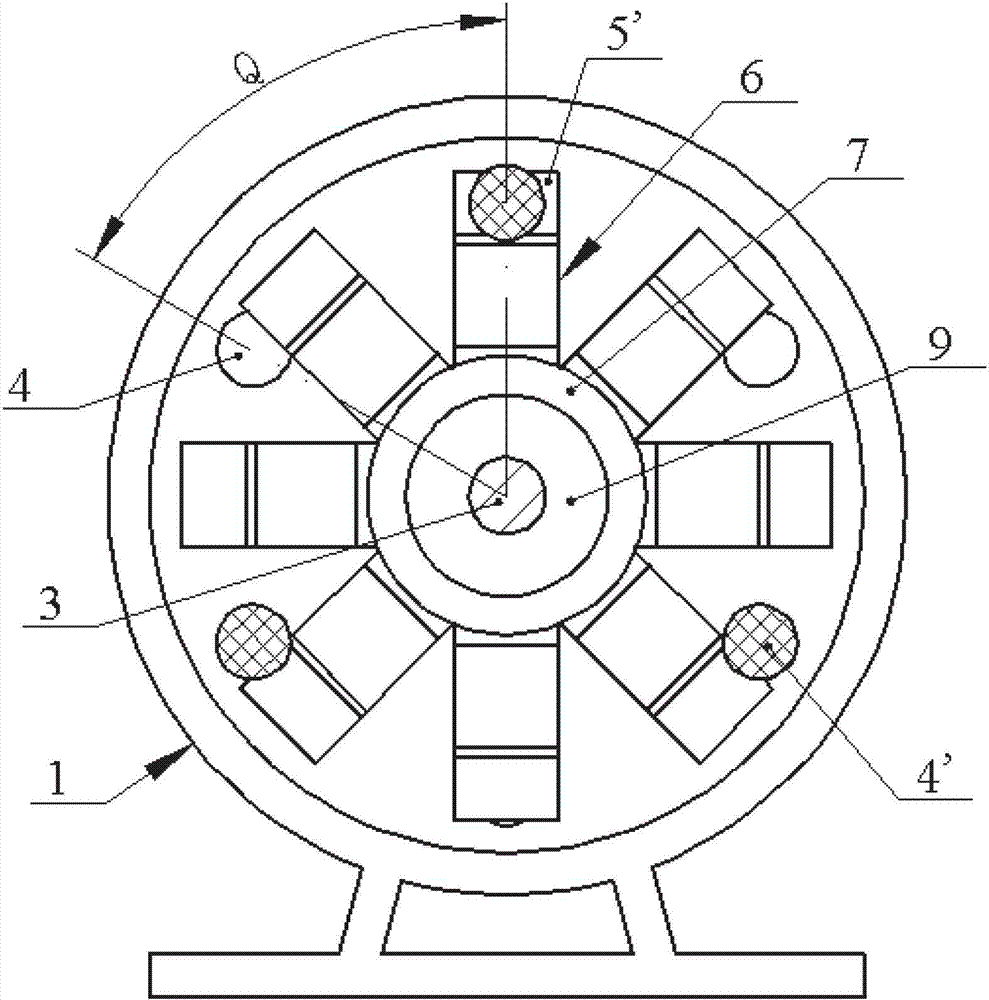

[0013] The side wall 101 of the frame 1 is inlaid with the bearing 2 and the first fixed magnet 4, and the end of the box body 102 of the frame 1 is equipped with a magnet frame 8 through screws, and the second fixed magnet 4 is inlaid on the magnet frame 8. '; one end 301 of the rotating shaft 3 is installed on the frame 1 through the bearing 2, and the cantilever beam piezoelectric vibrator 6, the retaining ring 7 and the monitoring system 9 are installed on the shoulder 302 of the rotating shaft 3 through screws; The piezoelectric vibrator 6 and the monitoring system 9 are connected through a wire group 10; the cantilever beam piezoelectric vibrator 6 is formed by bonding a metal substrate 601 and a piezoelectric chip 602; the first moving magnet 5 and the second moving magnet 5' pass through The screws are fixed on both sides of the free end of the cantilever beam piezoelectric vibrator 6; The same-sex magnetic poles of the first fixed magnet 4 on 101 are installed opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com