Method for achieving one-time molding of upset welding and wear-resistant welding of oil drill pipe

A technology for oil drill pipes and drill pipes, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of wear-resistant welding temperature drop, affecting the quality of thickening welding, etc., to save repair costs, welding and supporting equipment Small and lightweight, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

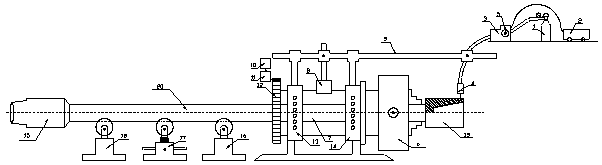

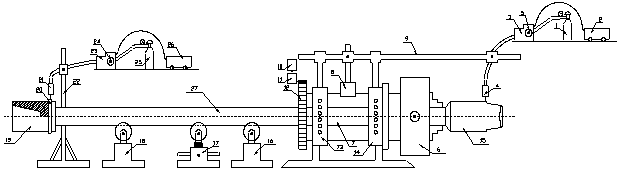

[0021] Below we will further elaborate on the method for realizing oil drill pipe thickening welding and wear-resistant welding of the present invention in combination with the accompanying drawings and specific embodiments, in order to more clearly understand the process method of the present invention and the required process equipment, but it cannot be used to limit the protection scope of the present invention.

[0022] The present invention is a process for realizing thickening welding and wear-resisting welding of petroleum drill pipe at one time. The method comprises the following steps:

[0023] In the first step, since the oil drill pipe includes a drill pipe body 20 and male joints 15 and female joints 19 respectively located at two ends thereof. And the male joint 15 and the female joint 19 of the oil drill pipe are the construction positions of the process method of the present invention. It is necessary to carry out thickening welding respectively on the male join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com