Advanced treatment process for coking wastewater by using resin in multistage fluidized-bed

A technology for coking wastewater and resin flow, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of intermittent operation of adsorption and regeneration, complex operation and management, and utilization of resin exchange capacity Low efficiency and other problems, to achieve the effect of high utilization rate of resin and equipment, high degree of integration, and stable treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

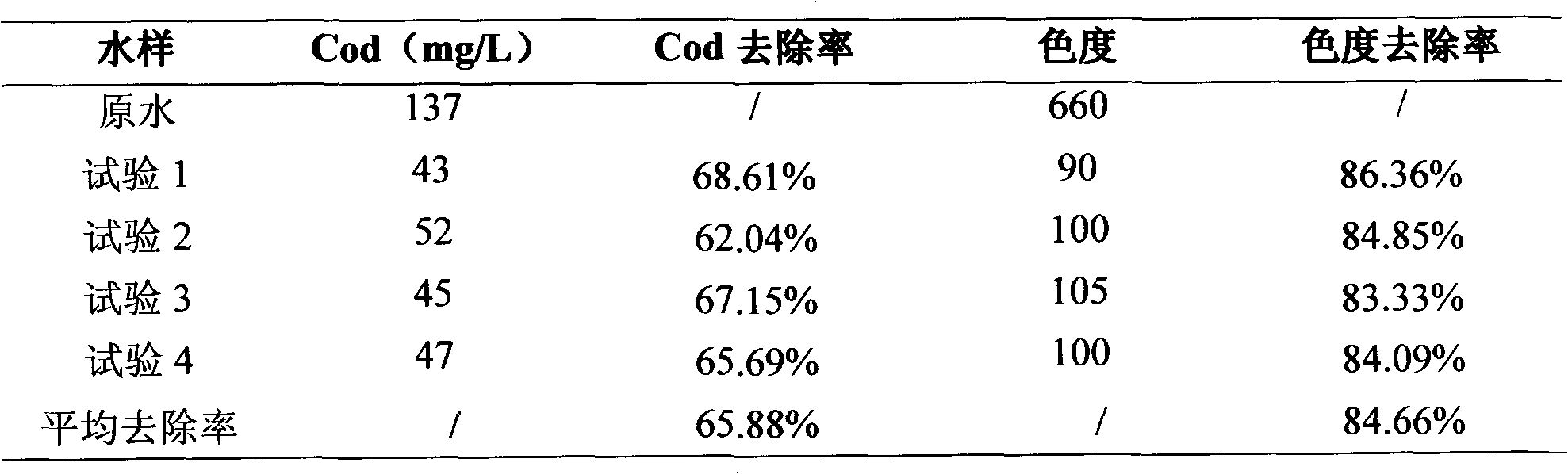

[0022] Using the treatment process of the present invention, the coking wastewater of a certain enterprise was subjected to advanced treatment, and the same water sample was used to carry out 4 tests in total.

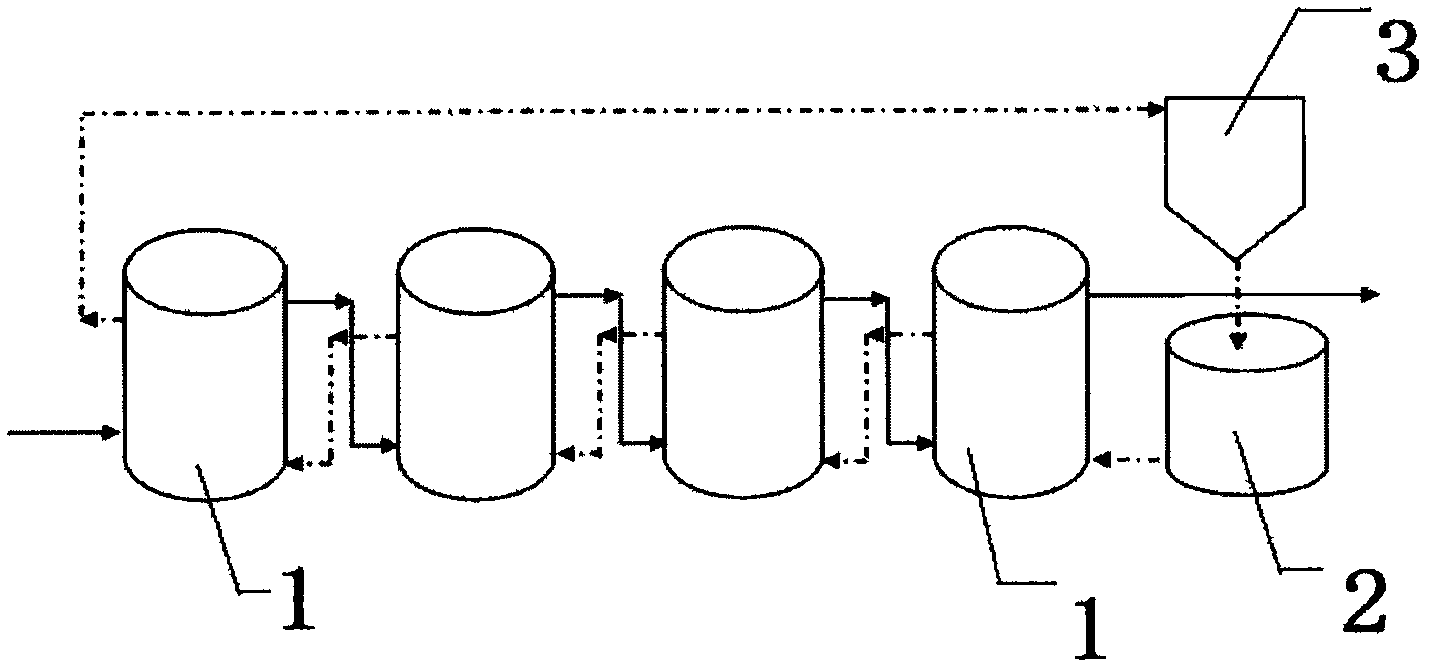

[0023] Coking wastewater enters from the water inlet at the bottom of the first-stage reactor, fully contacts and stirs with the resin, and the effluent enters the second-stage reactor from the bottom of the second-stage reactor through overflow, and reacts with the resin in the second-stage reactor, coking wastewater After the 6-stage reaction, water is discharged from the 6-stage reactor;

[0024] The resin enters from the bottom of the 6-stage reactor, moves with the water to the upper part of the reactor, and fully contacts and stirs with the coking wastewater. It reacts with coking wastewater, and after the 6-stage reaction, the resin is discharged from the 1st-stage reactor, pumped into the transfer tank, and the resin is regularly discharged into the regeneratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com