Anchoring device used between FRP (Fiber Reinforced Plastic) pipe and metal bar

A technology of anchoring devices and metal rods, which is applied in the direction of construction and building construction, can solve the problems of difficult alignment, large size of anchoring devices, and inconvenient construction, and achieve easy alignment, high coaxiality, and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The utility model will be further described below in conjunction with the accompanying drawings.

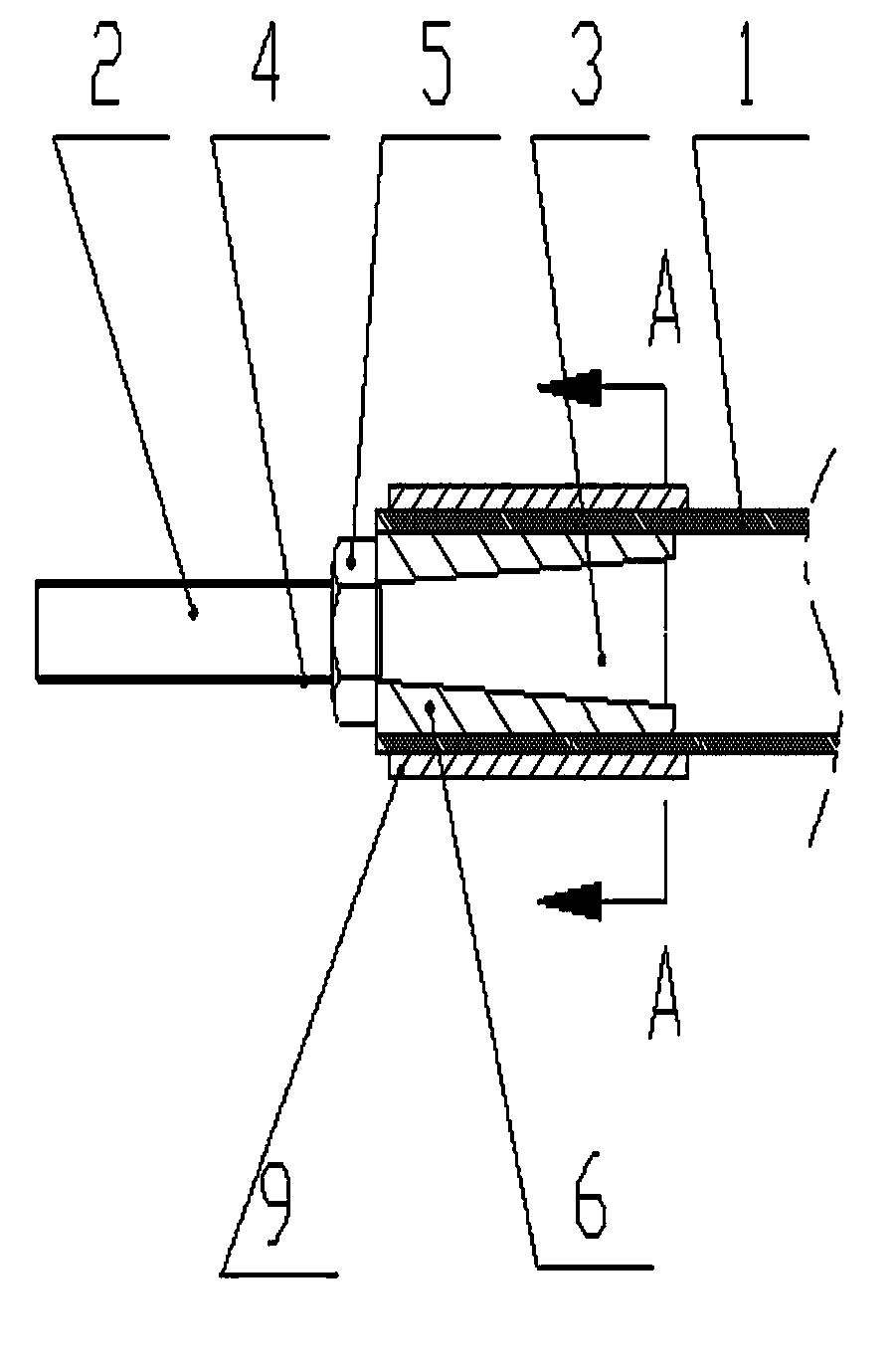

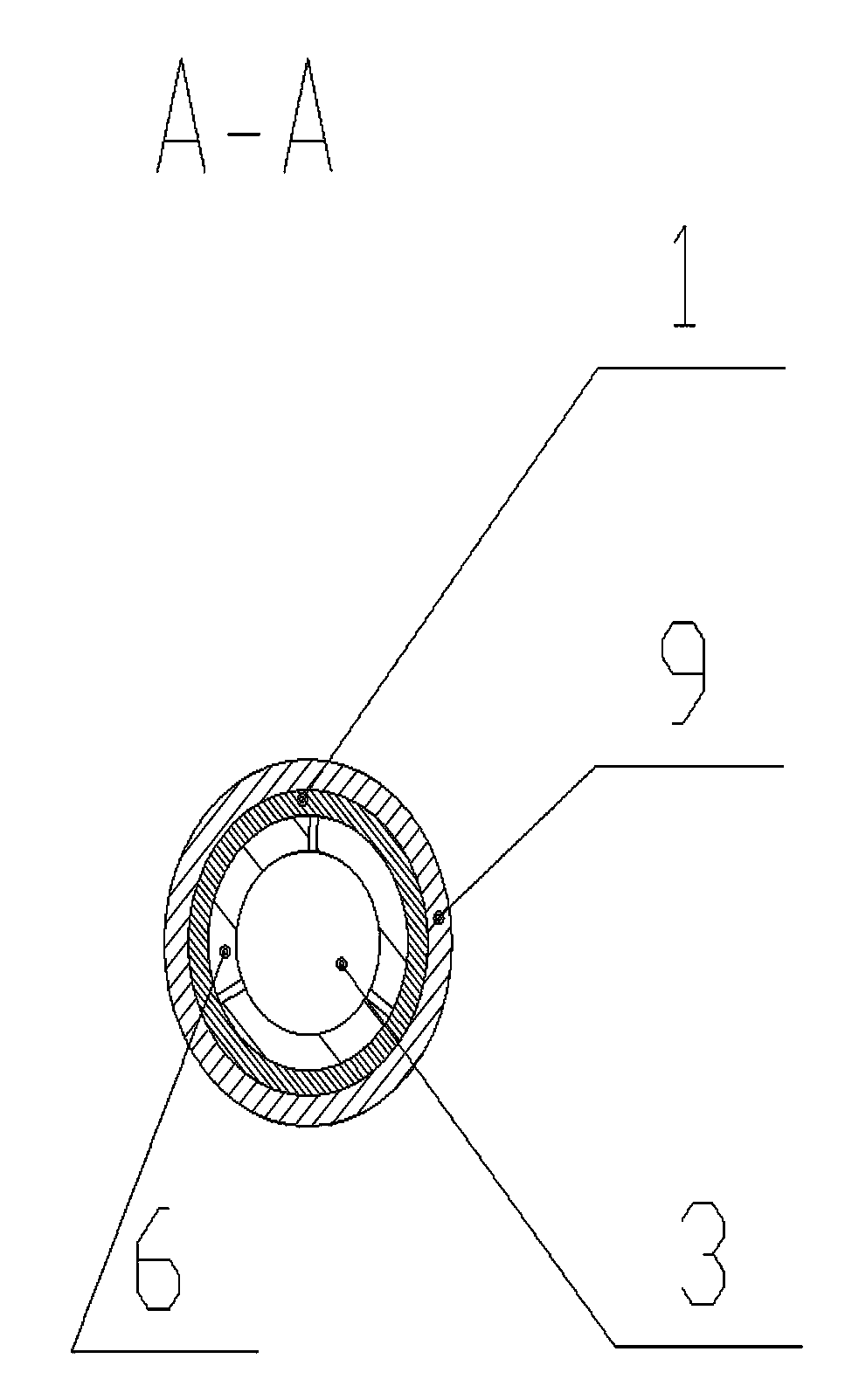

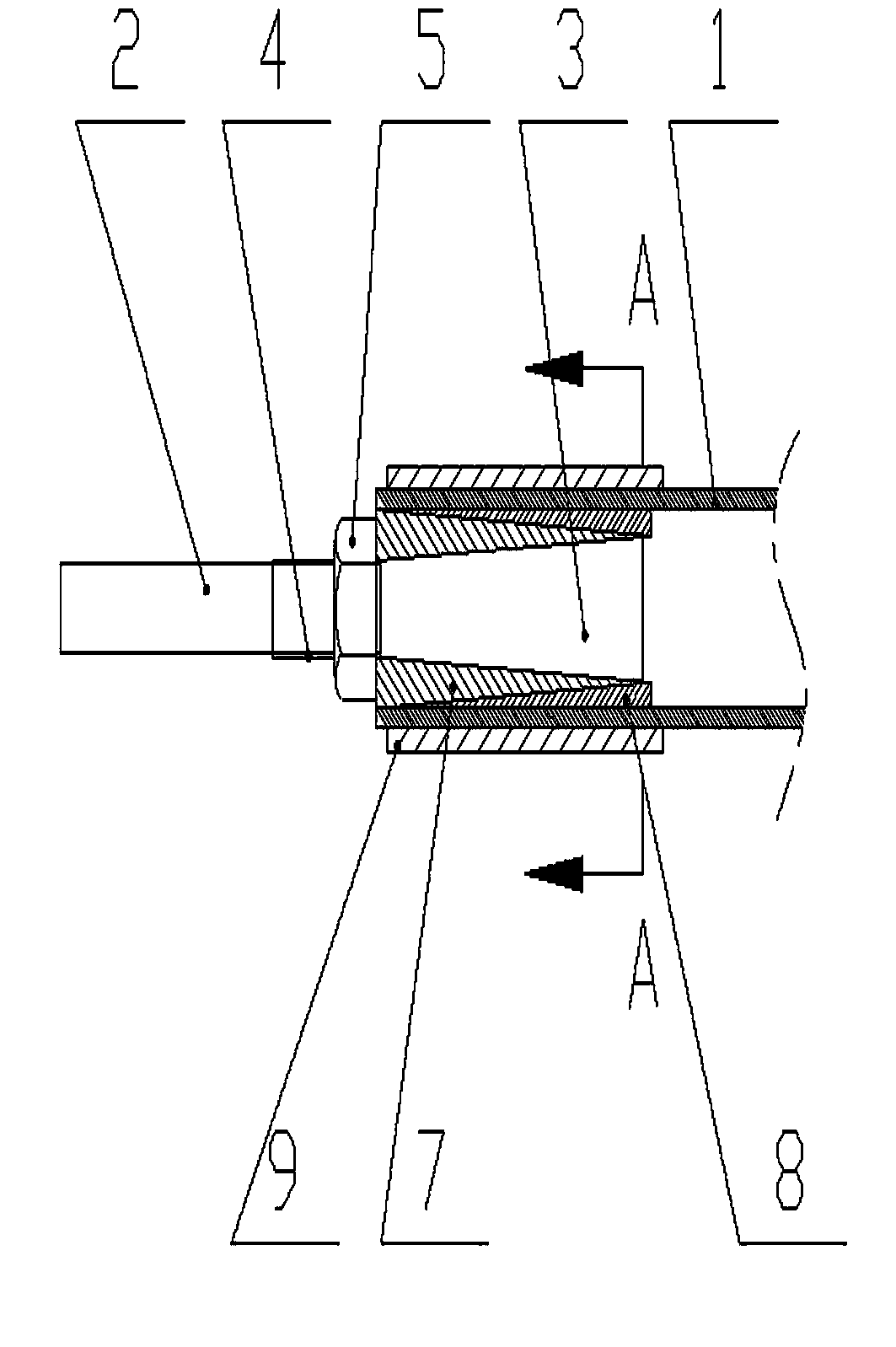

[0011] like figure 1 As shown in , 2, the present invention includes a FRP pipe body 1 and a metal rod body 2, one end of the metal rod body 2 is located in the FRP pipe body 1, the front end of the metal rod body 2 is provided with a circular truncated end 3, and the metal rod body 2 is connected with the circular The small end face of the truncated end 3 is connected, and the surface of the metal rod body 2 close to the truncated truncated end 3 is provided with an external thread 4, and the external thread 4 has a matching nut 5; There are also at least two clips 6 between them. further, as figure 1 , 2, there are three clips. The three clips have the same shape and are evenly distributed around the axis of the metal rod body 2 . The shape of the inner surface of the clip 6 matches the side surface of the truncated truncated head 3 , the outer surface of the clip 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com