Mud mixing system with performance parameter intelligent detecting function and detecting method

A technology of intelligent detection and detection method, which is used in earth-moving drilling, wellbore/well components, flushing wellbore, etc., which can solve the problems of cumbersome and time-consuming operation, low detection efficiency, and incompact measurement-adjustment connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

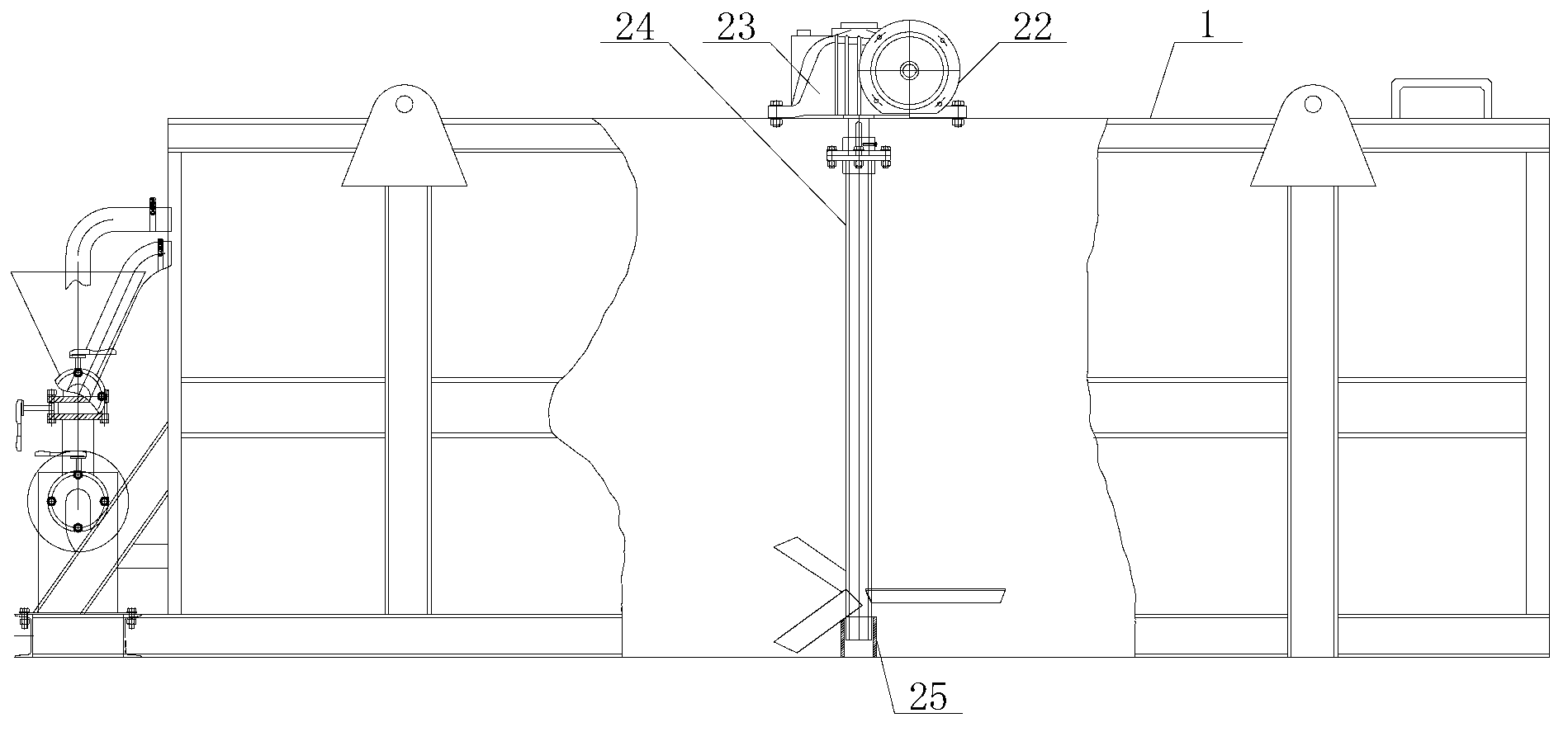

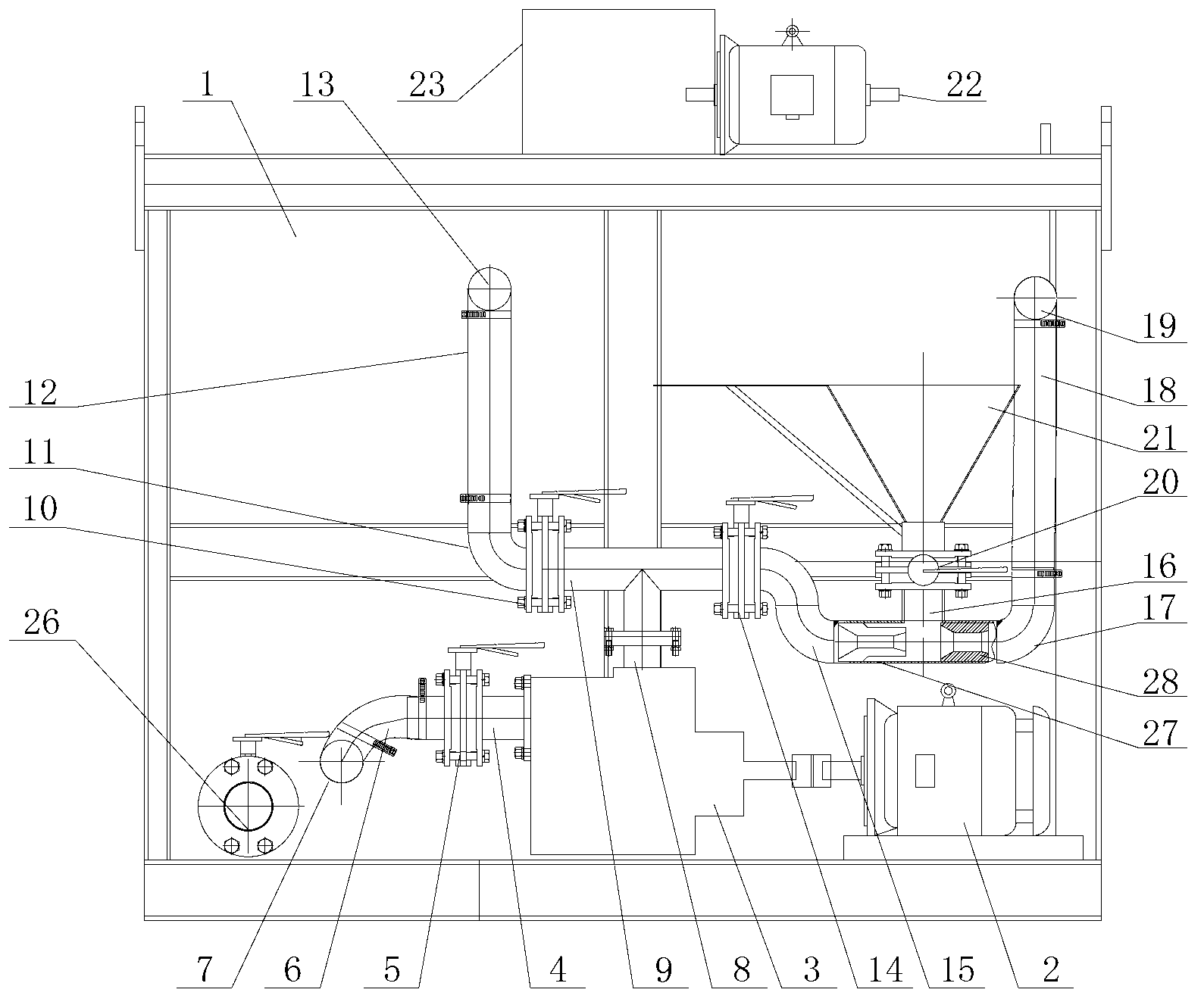

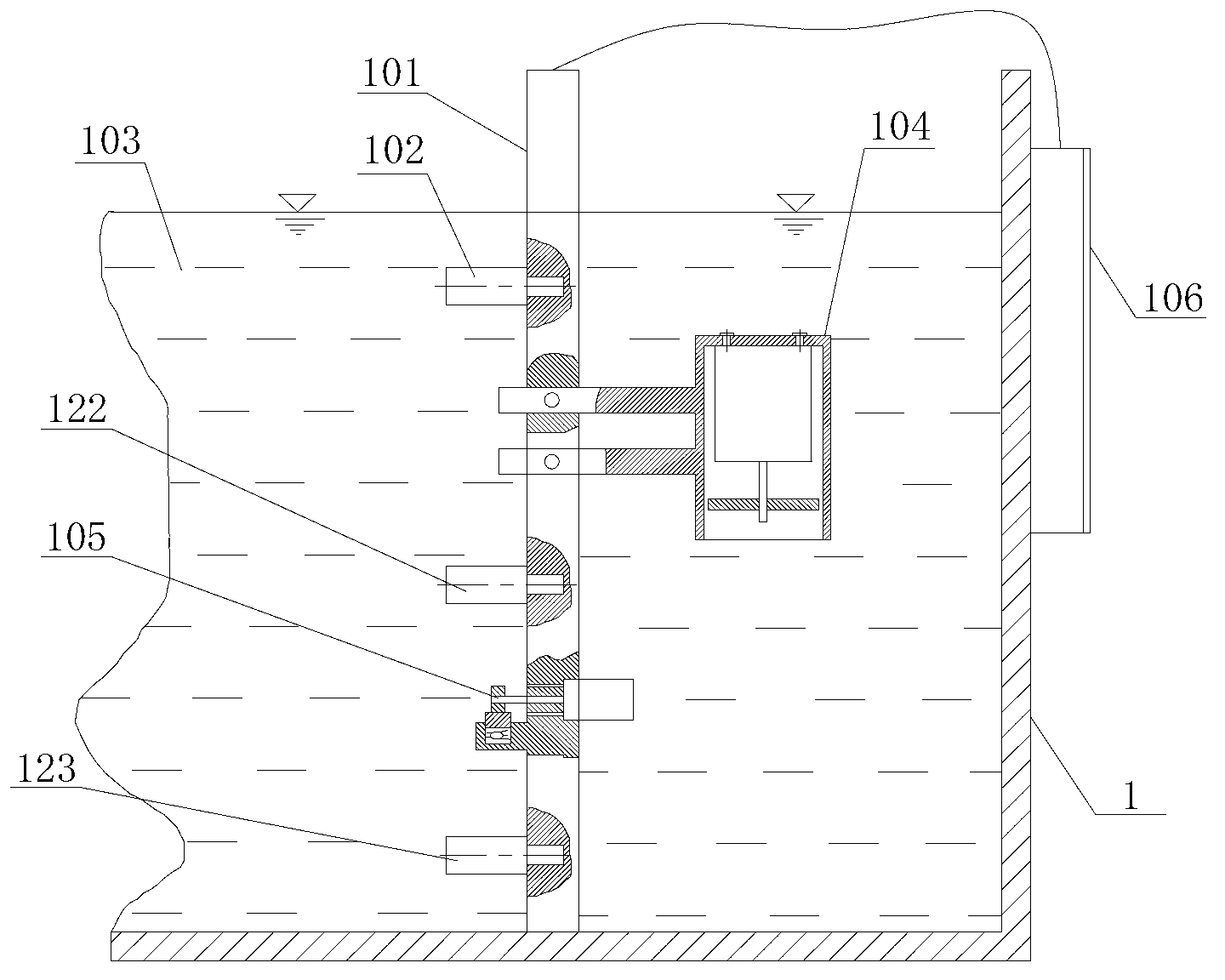

[0044] see Figure 1~6 As shown, a mud mixing system with intelligent detection function of performance parameters includes: mud mixing system and mud performance intelligent detection system, the organic combination of the two is convenient for on-site use.

[0045] Among them, the mud mixing system includes a mixing tank 1 for holding mud, and a mud self-circulation system for sucking out the mud in the mixing tank 1 and returning it to the mixing tank, and a mud self-circulation system for sucking out the mud in the mixing tank 1 and feeding it. The mud feeding circulation system that is discharged back into the mixing tank, the mud mixing system and the slag discharge system used to stir the mud in the mixing tank 1 evenly.

[0046] see figure 1 , figure 2 As shown, the stirring tank 1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com