Subsurface electric control stepless position adjusting structure

An adjustable structure, stepless technology, applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problem that remote control tools are difficult to realize electric drive, and achieve the effect of reducing assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

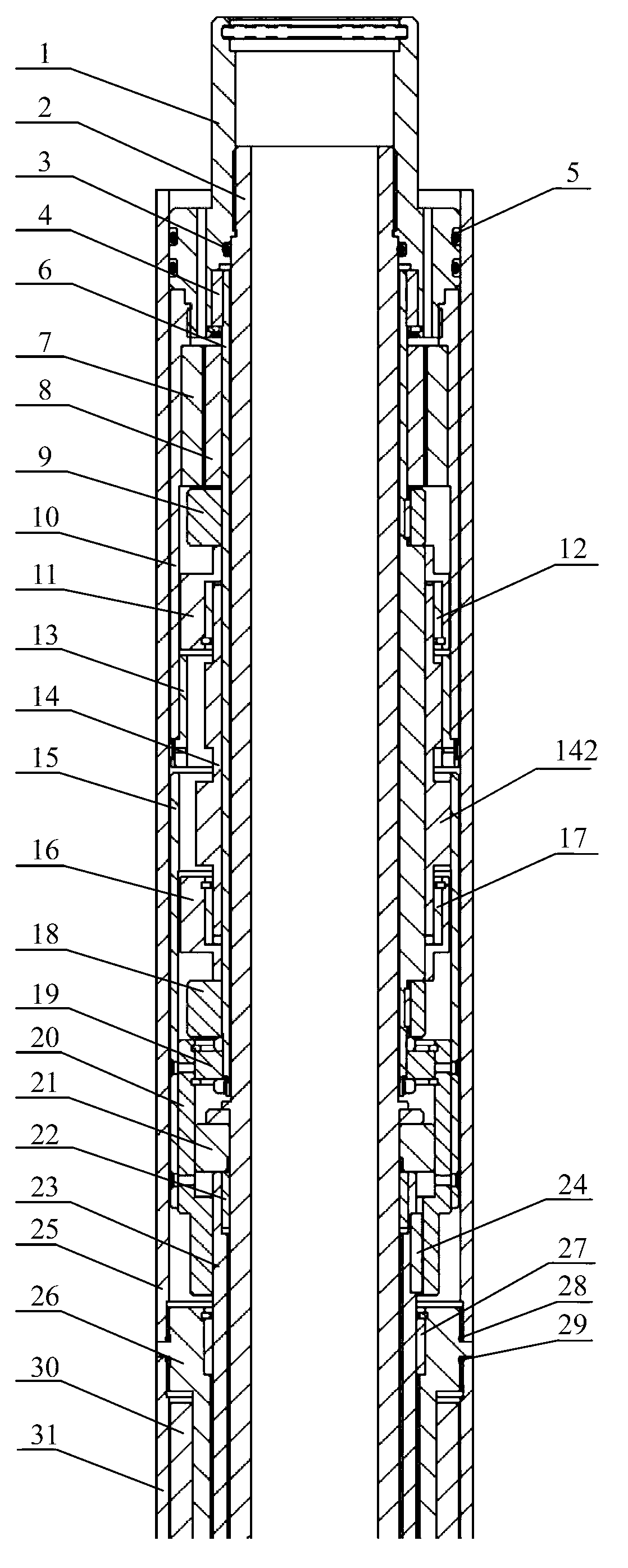

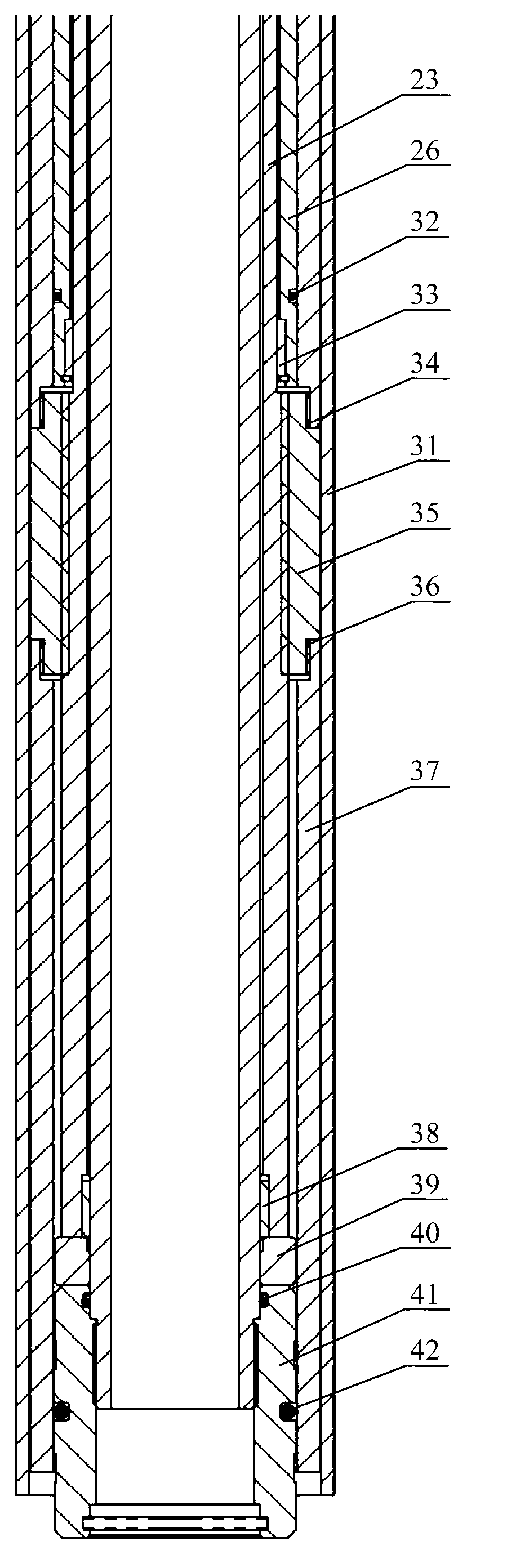

[0025] Such as figure 1 with figure 2 As shown, the downhole electronically controlled stepless position adjustment structure according to the embodiment of the present invention includes: a base pipe 2 and a motor, a deceleration device and a transmission device sleeved on the base pipe 2 . The motor, deceleration device and transmission device are all ring-shaped, so as to make full use of the annular space of the oil casing annulus, and realize the relative position adjustment of downhole components without affecting the liquid flow channel of the base pipe.

[0026] The motor includes: an annular motor output shaft, and the annular motor output shaft is rotatably sleeved on the base pipe 2 . Further, the motor is, for example, a ring-shaped motor or a ring-shaped permanent magnet synchronous motor, and the motor also includes: a ring-shaped stator 7 and a rotor 8 arranged between the stator 7 and the ring-shaped motor output shaft, and the rotor 8 Located in the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com