Bolt group

A bolt group and bolt technology, applied in the directions of bolts, screws, nuts, etc., can solve the problems of nut falling off, hidden troubles, loose connection nuts, etc., and achieve the effect of convenient installation and disassembly, strong applicability, and enhanced anti-loosening performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

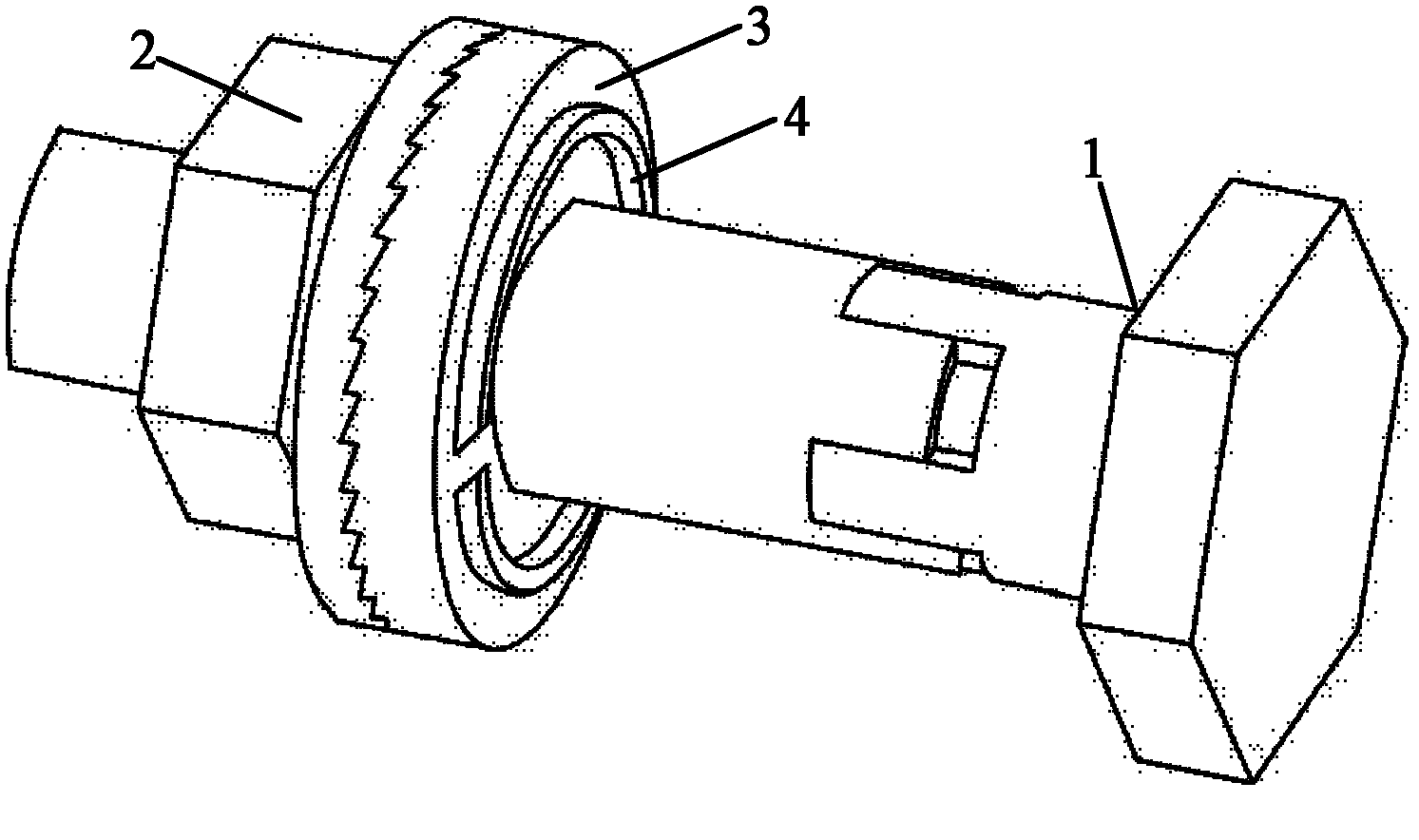

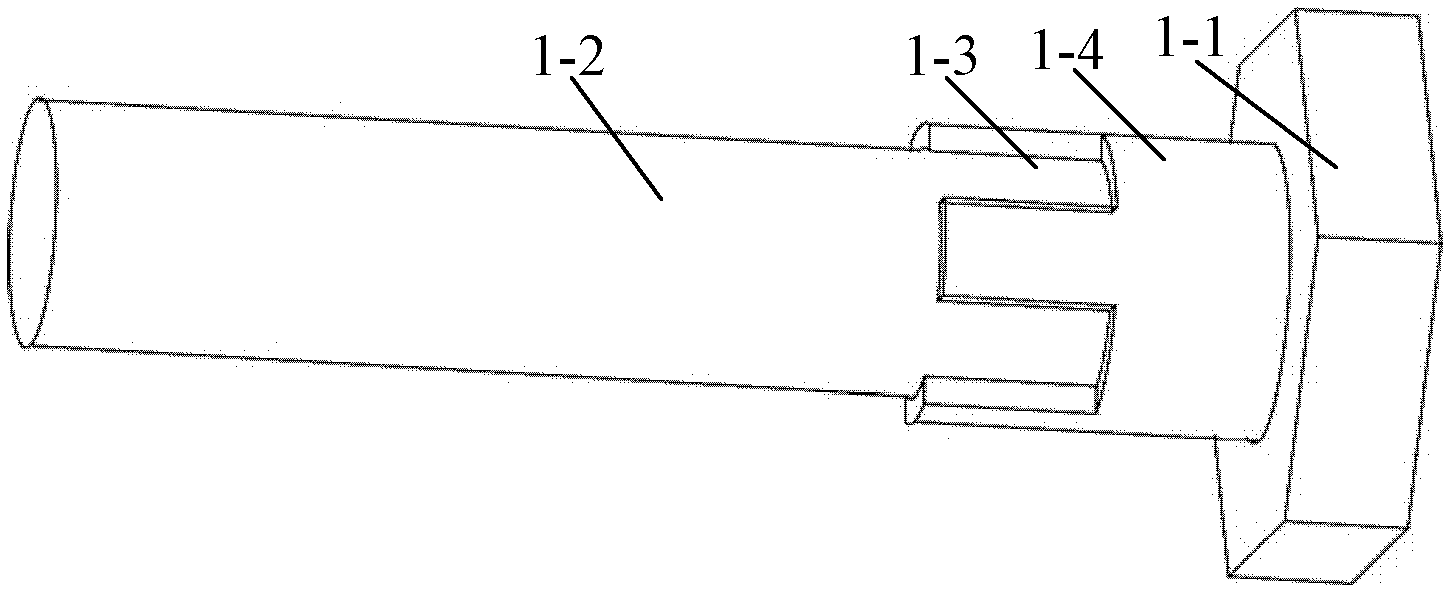

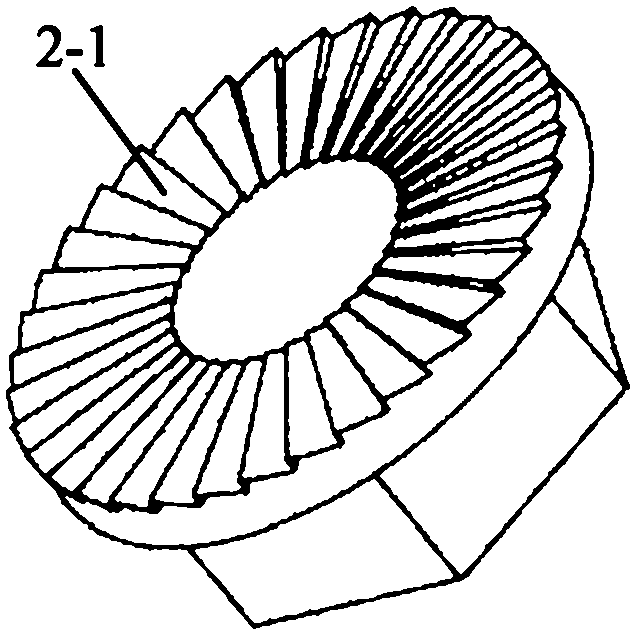

[0025] figure 1 A schematic structural diagram of a bolt group according to an embodiment of the present invention is shown, which includes a bolt 1 and a nut 2, and the bolt 1 and the nut 2 are connected by common threaded locking. In order to prevent the loosening between the bolt 1 and the nut 2, the bolt group of the present embodiment adds an anti-loosening fastening sleeve 3, and the fastening sleeve 3 is arranged between the bolt head 1-1 and the nut 2, and the fastening A set of one-way ratchets are provided on the opposite end surfaces of the sleeve 3 and the nut 2 in the radial direction, and the two sets of ratchets are engaged, and the loosening direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com