Production technology of optical fiber combiner based on capillary tube

A technology of optical fiber combiner and production process, which is applied in the field of optical fiber coupling, can solve problems such as low technical level, achieve the effect of regular and convenient fiber arrangement, reduce complexity, and reduce energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

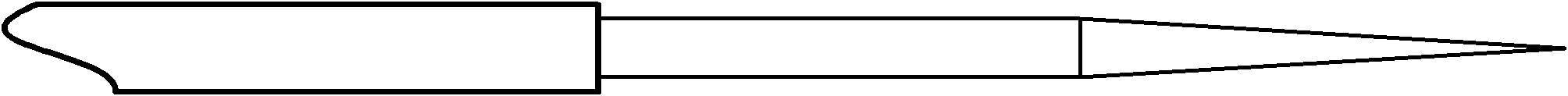

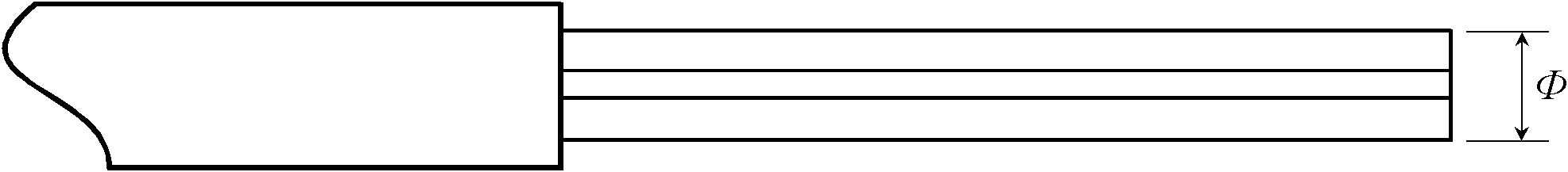

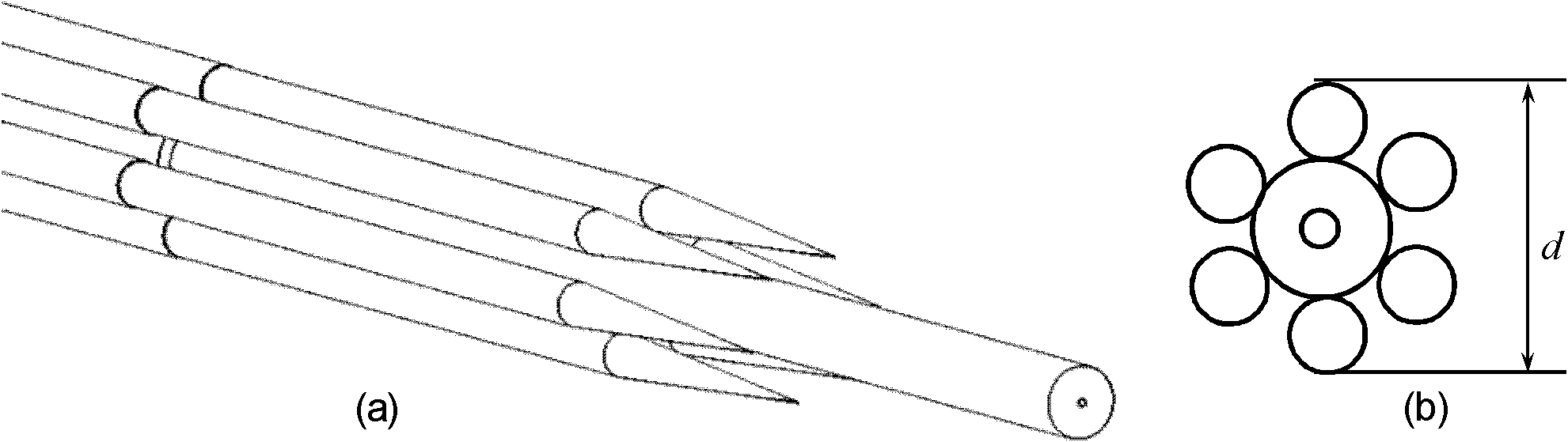

[0040] The present invention provides a novel capillary tapering method for fiber optic combiners, and develops a (N+1)×1 fiber laser pump combiner, which is mainly used to solve the problem of fiber laser pumping Combination problem, to achieve high-power semiconductor laser pumping of fiber lasers, different from the traditional fusion taper method, in this scheme, use quartz (or glass and other materials) capillary tubes as bundled fiber bundles (N tapered The multimode pump optical fiber and one transmission optical fiber are regularly stacked into a bundled fiber bundle) on the external frame, and the capillary is tapered, which realizes the overall tapering of the bundled optical fiber, and the bundled fiber bundle is fused with the capillary wall. As a whole, a tapered optical waveguide is formed to realize the combination of multiple laser beams.

[0041]After the tapering is completed, the bundled fiber bundle formed by N tapered multimode pump fibers and 1 signal tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com