Circuit board structure and packaging structure for IGBT (insulated gate bipolar transistor) module

A technology of circuit boards and sub-modules, applied in the direction of circuits, printed circuits connected with non-printed electrical components, electrical components, etc., can solve the problems of restricting the application of large-capacity power electronic commutation systems, difficulty in manufacturing, and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

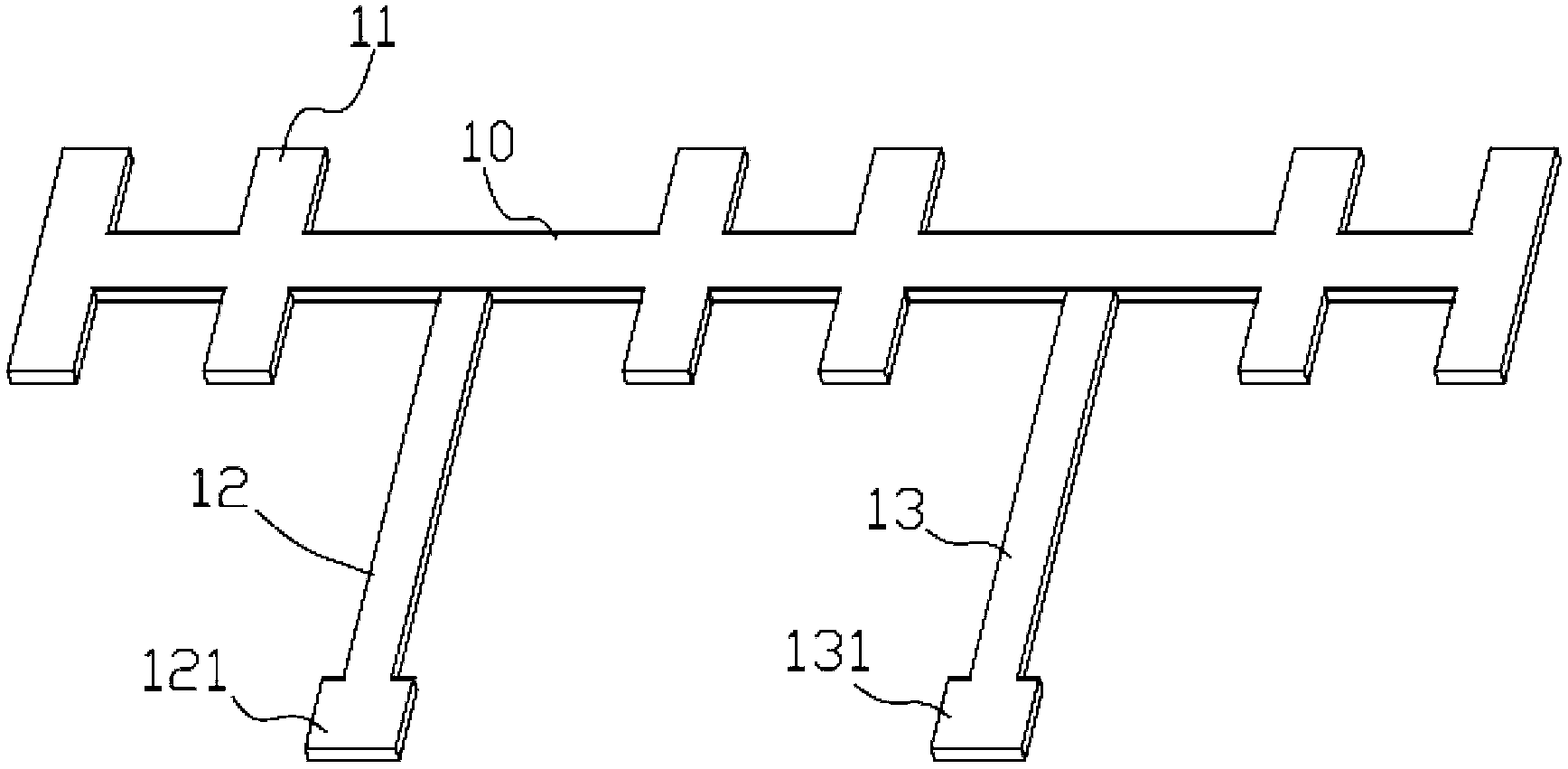

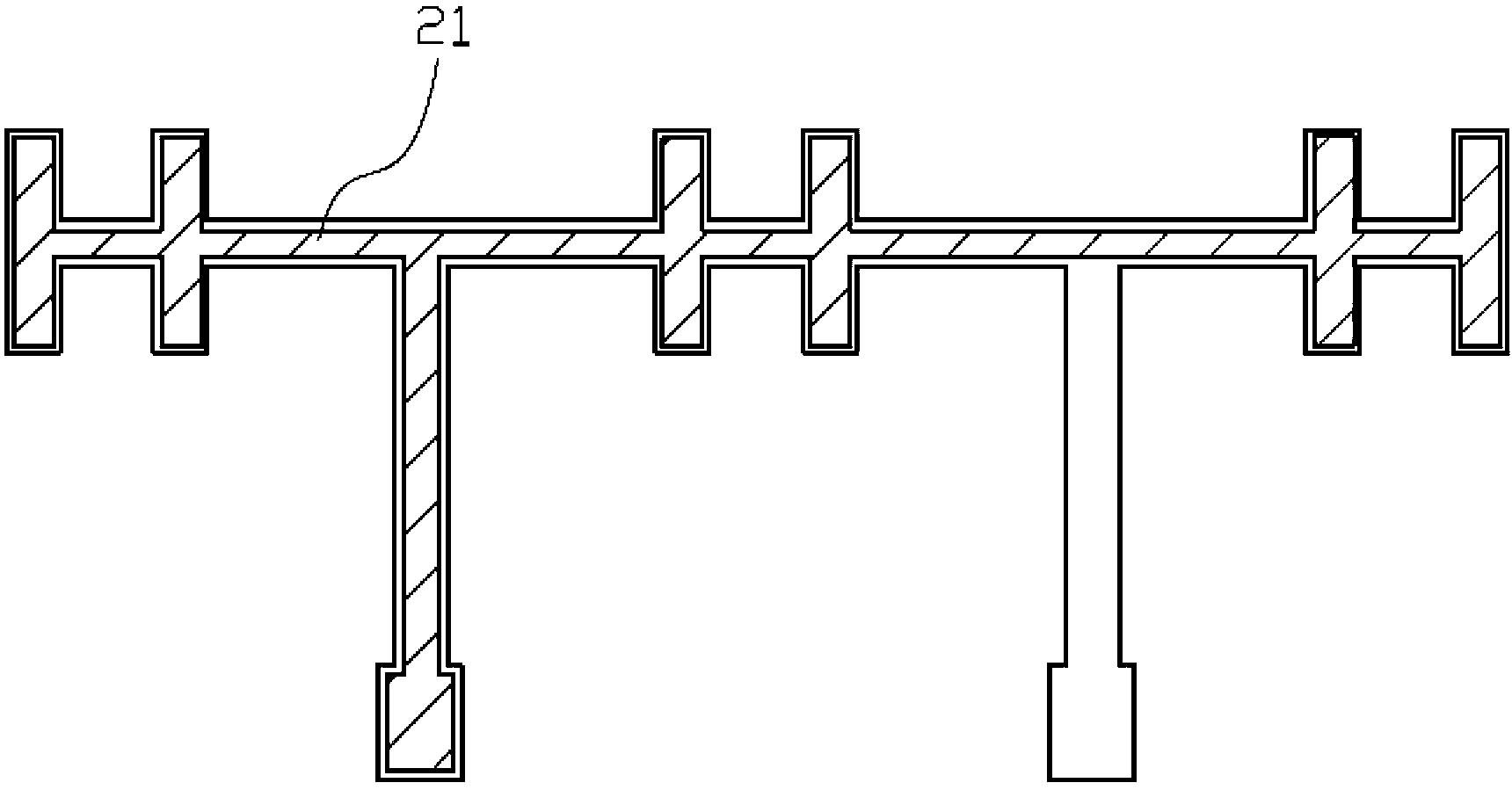

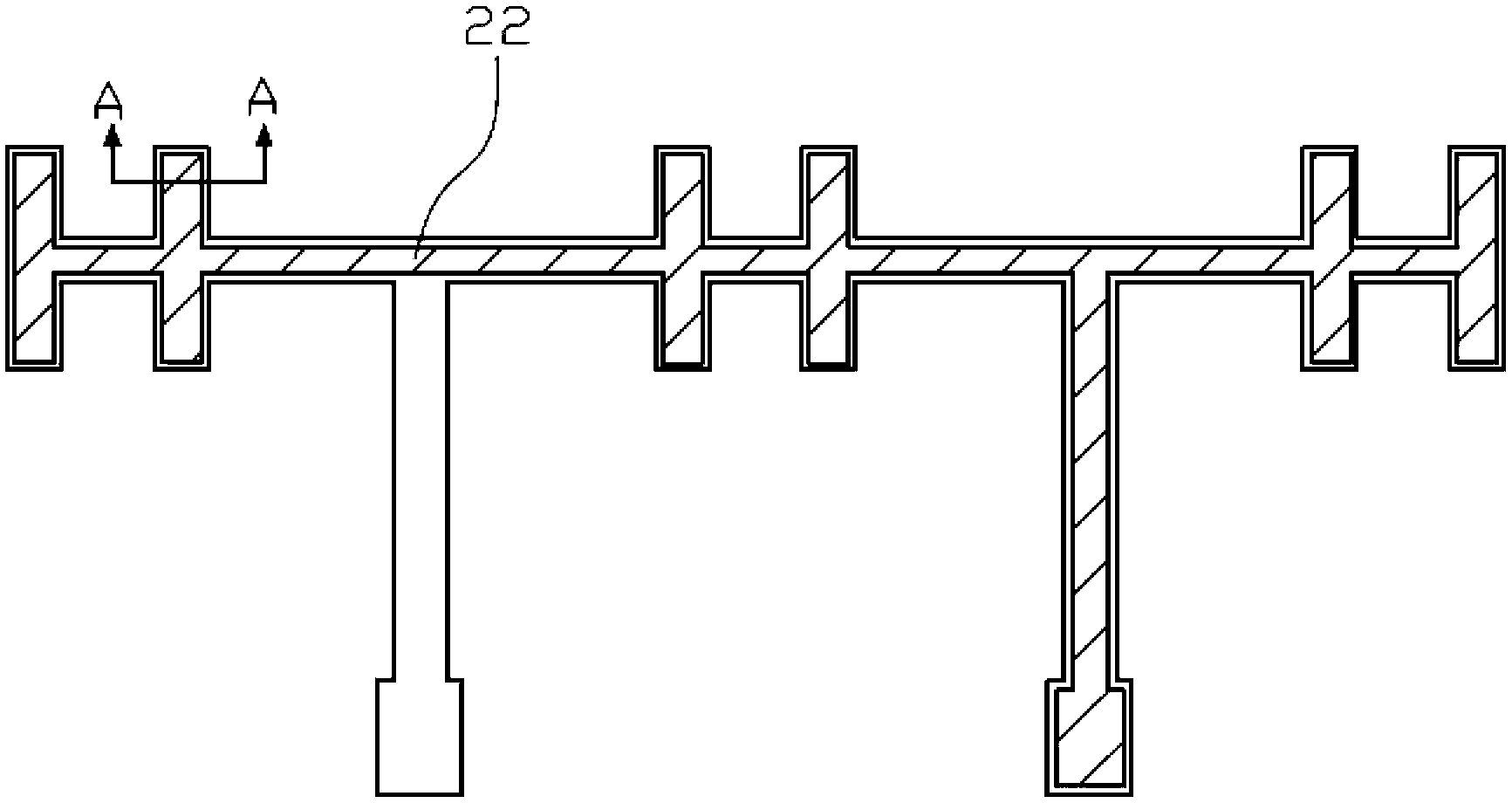

[0021] As described in the background art, in the existing IGBT module packaging technology, how to achieve simple and effective control electrode extraction has always been an unresolved problem. Aiming at this problem, the present invention proposes a circuit board structure in the IGBT module packaging process. Through the circuit board, the control electrodes on each sub-module in the IGBT module can be easily drawn out. Especially in the flat-plate press-fit packaging process, the gate and emitter of each parallel IGBT sub-module can be accurately led to the control terminal through the circuit board structure of the present invention, thereby realizing effective electrical control of the entire IGBT module. .

[0022] The technical solutions of the present invention will be clearly and completely described below through specific embodiments. Obviously, the described embodiments are only some, but not all, embodiments of the present invention. Based on the embodiments o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Minimum width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com