Moire magnification device

A technology of ripple amplification and safety devices, applied in printing, optics, instruments, etc., can solve the technical difficulties of discrete micro-image arrays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

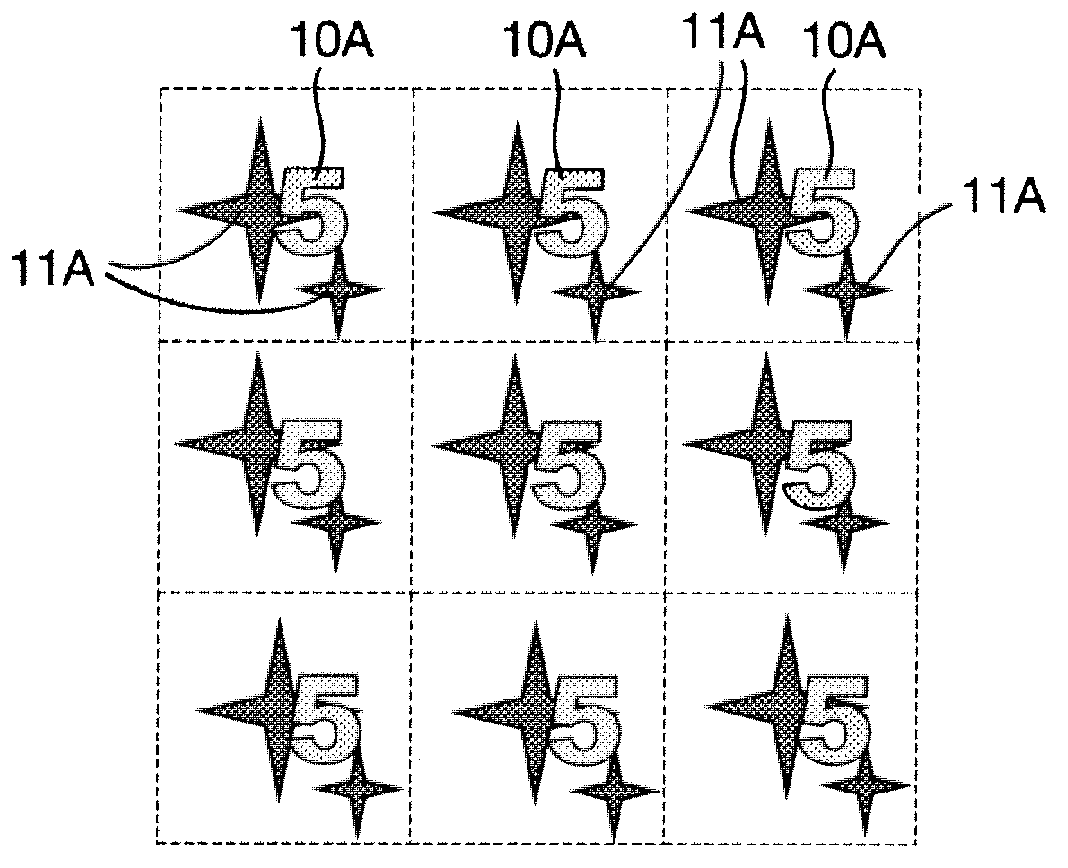

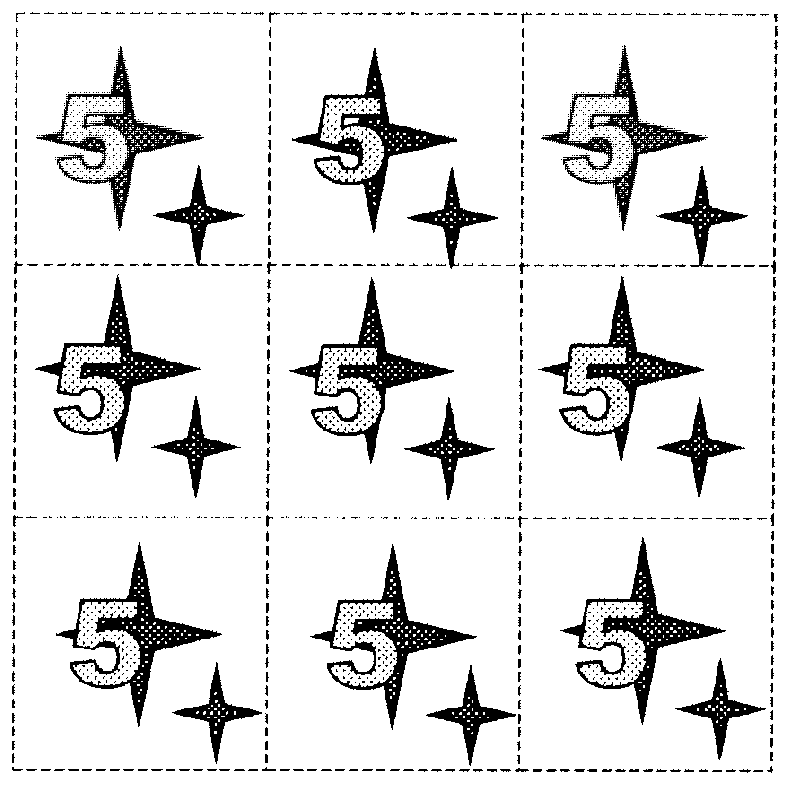

[0084] Assuming Figure 2 and Figure 5 The structure consists of a microlens 22 with a focal length f of 40 μm or 0.04 mm. In addition, it is assumed that both the microlens and the support substrate 20 are composed of a material having a refractive index n of 1.5. Thus, it follows that the bottom diameter D of the lens is defined by the following expression: D≤f*2(n-1), therefore D≤0.04*2(1.5-1), resulting in D≤0.04mm.

[0085] A value of 0.035mm can then be chosen for D, and a value of 0.04mm (along each axis) for lens spacing B (along each axis), so that the lens array has an f / # number close to 1, with reasonable close packing (lens The gap is 5 μm).

[0086] In the first embodiment, it is assumed that the first image array 10 is required to be located at 2 mm behind the surface plane of the substrate, and the second image array 11 is located at 6 mm behind the surface plane, (note that by definition, the surface plane behind images are virtual, and a more detailed anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com