Internal combustion engine having two lubricating chambers separated from one another in a fluid-tight manner

An internal combustion engine and space technology, which is applied to the lubrication of valve accessories, lubricating parts, lubricant conduit devices, etc., can solve problems such as incomplete solutions, and achieve the effect of shortening heat resistance and avoiding long-term wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

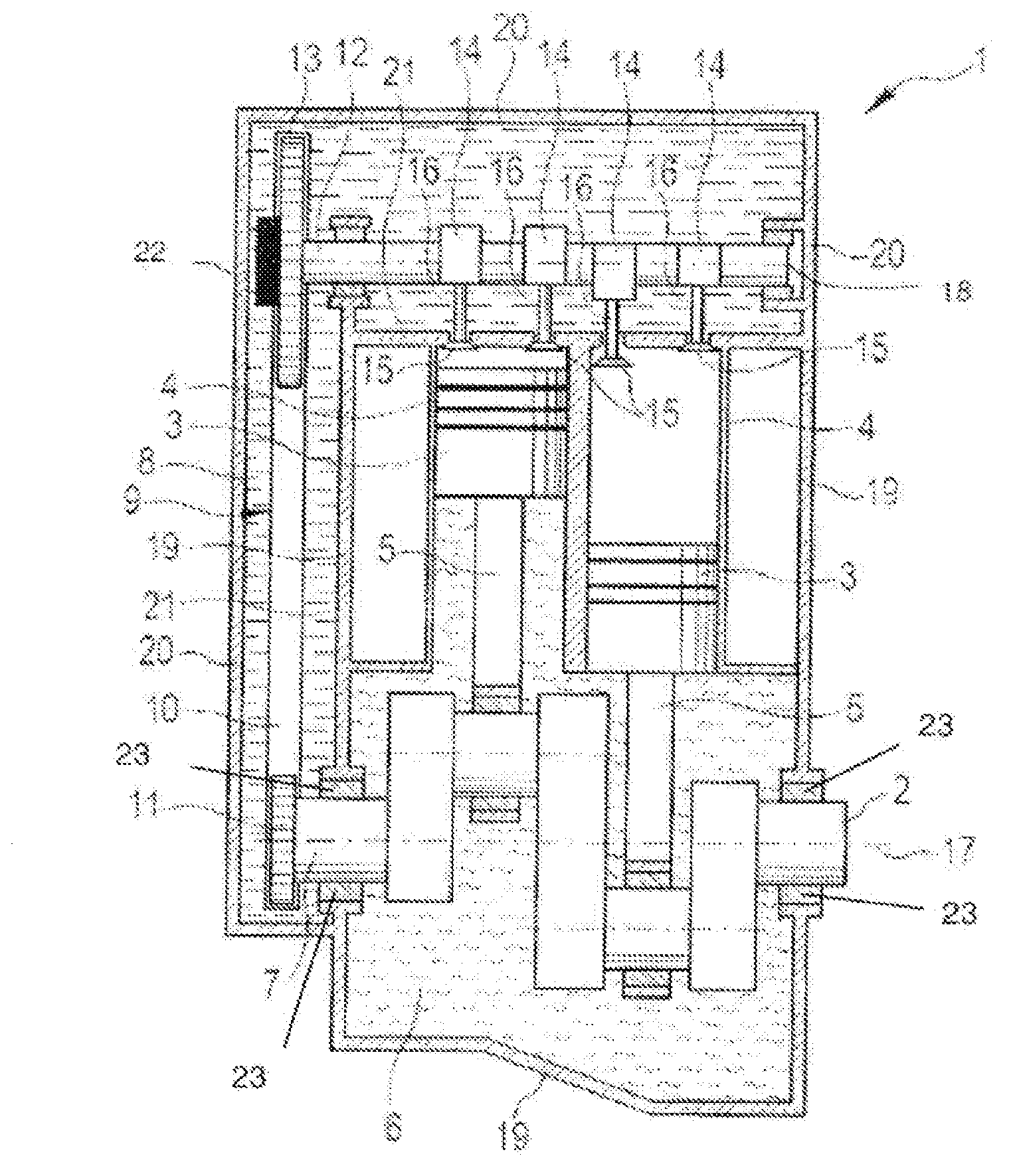

[0032] figure 1 The illustration of the internal combustion engine 1 is only schematic in nature and serves only for the understanding of the invention.

[0033] Internal combustion engine 1 has a crankshaft 2 , which is driven by two pistons 3 here by way of example. exist figure 1 The two pistons 3 shown in are arranged linearly movable in two cylinders 4 . Not shown, the cylinder 4 also includes a cylinder sleeve. The movement of the piston 3 is transmitted to the crankshaft 2 via the connecting rod 5 . Only sufficiently known connecting rod bearings are shown.

[0034] Also only the bearings of the crankshaft 2 are shown.

[0035] The crankshaft 2 is mainly arranged in the first space 6 . Only a small end section 7 of the crankshaft 2 protrudes from the first space 6 into the second space 8 . A synchronous transmission 9 is also provided in the second space 8 . The synchronous transmission 9 includes a traction mechanism 10 which is in operative contact with a gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com