Polarizing film application device and system of manufacturing liquid crystal display device provided with same

A technology of laminating device and polarizing film, which is applied to identification devices, polarizing elements, optics, etc., can solve problems such as low productivity, and achieve the effects of simple setup, excellent area efficiency, and short production interval.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

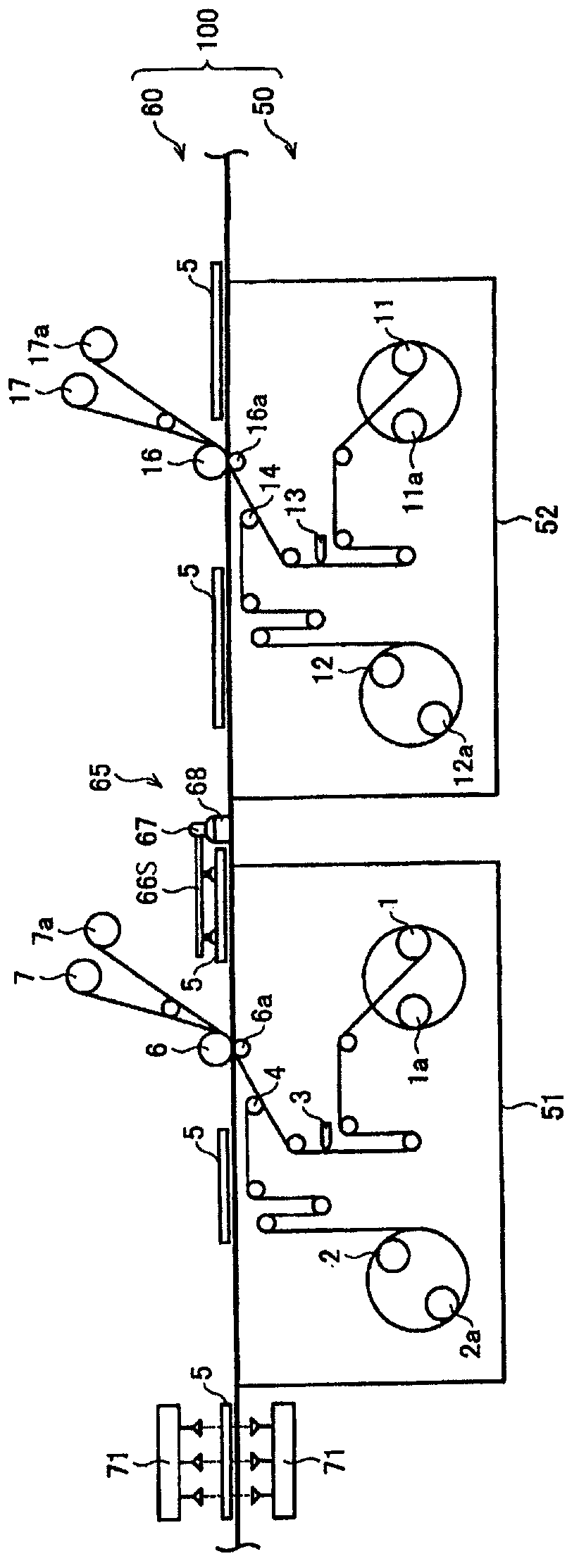

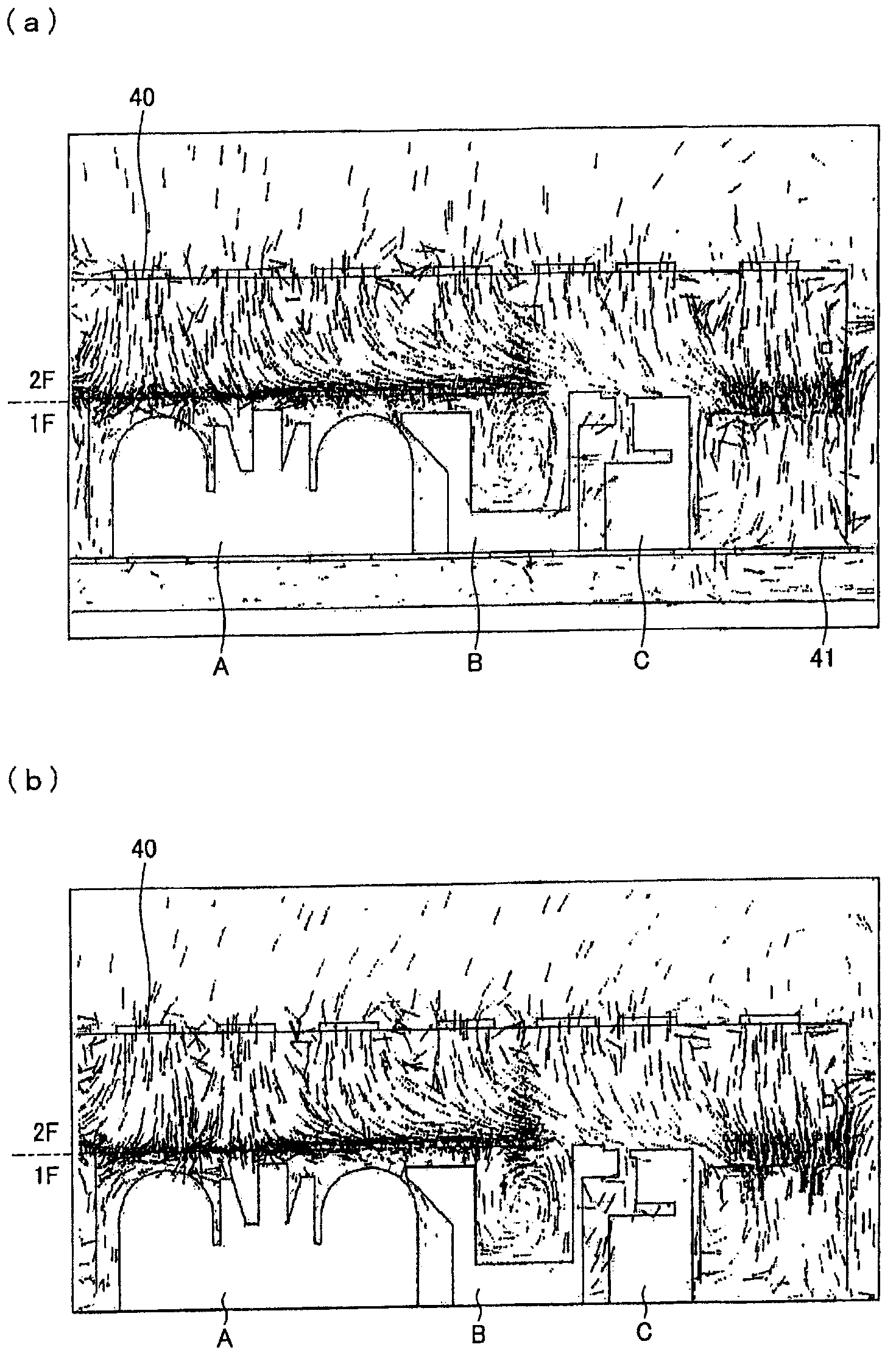

[0141] For an embodiment of the present invention, according to Figure 1 to Figure 9 The description is as follows, but the present invention is not limited thereto. First, the configuration of the manufacturing system (liquid crystal display device manufacturing system) of this embodiment will be described below. The manufacturing system includes the bonding device of the present invention.

[0142] figure 1 is a sectional view showing the manufacturing system. As shown in the figure, the manufacturing system 100 has a two-stage structure, 1F (1st floor) part is the film conveyance mechanism 50, and 2F (2nd floor) is the bonding apparatus 60 including the board|substrate conveyance mechanism.

[0143]

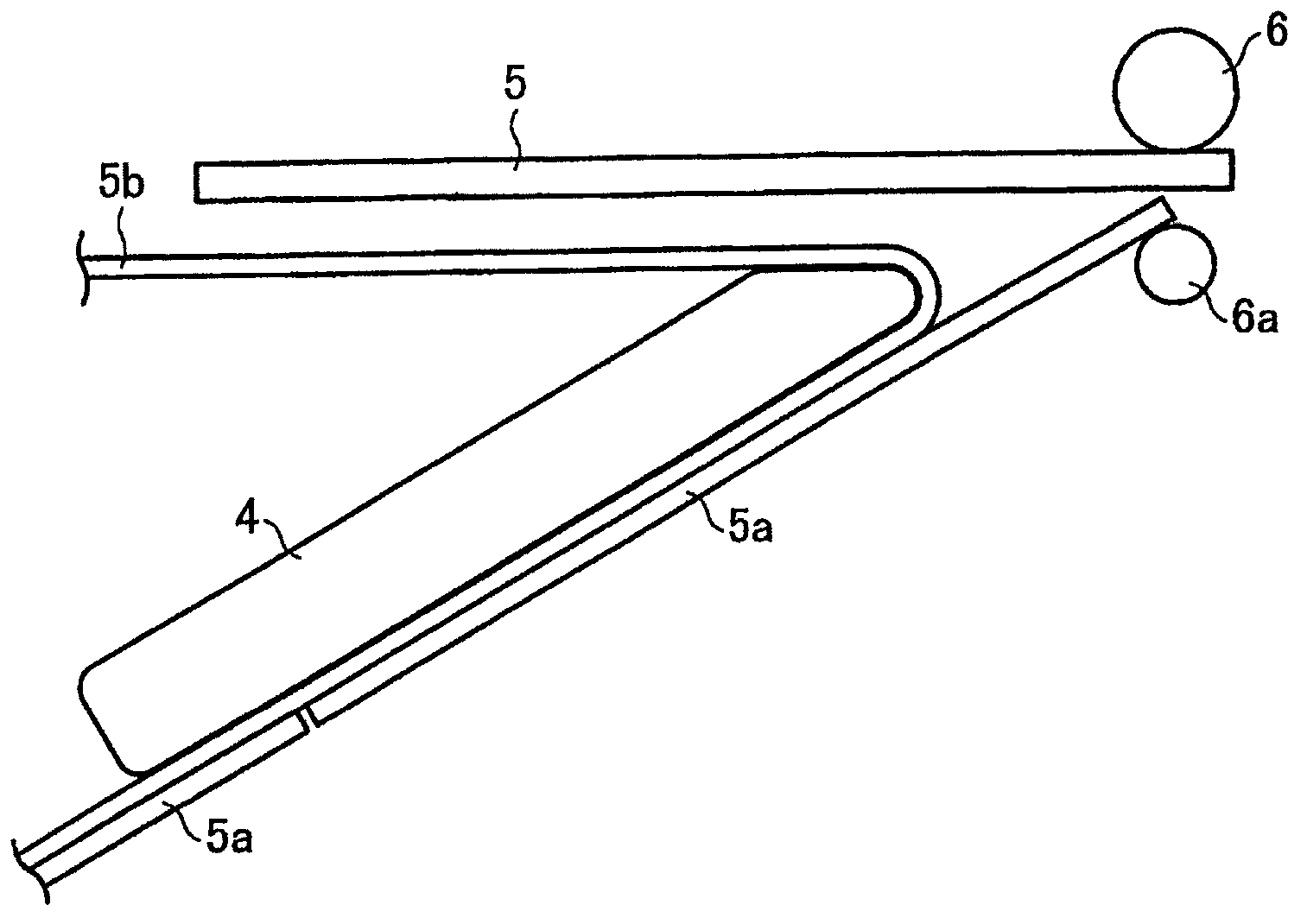

[0144] First, the film transport mechanism 50 will be described. The film conveying mechanism 50 unwinds the polarizing film (polarizing plate) and conveys it to the nip rollers 6, 6a and 16, 16a, and plays a role of winding up an unnecessary release film. On the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com