Hanging bucket type semi-automatic crop transplanting machine

A crop and semi-automatic technology, applied in the direction of transplanting machinery, agriculture, application, etc., can solve the problems of inapplicability, troublesome operation, impact, etc., and achieve the effect of achieving precise changes and reducing work resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

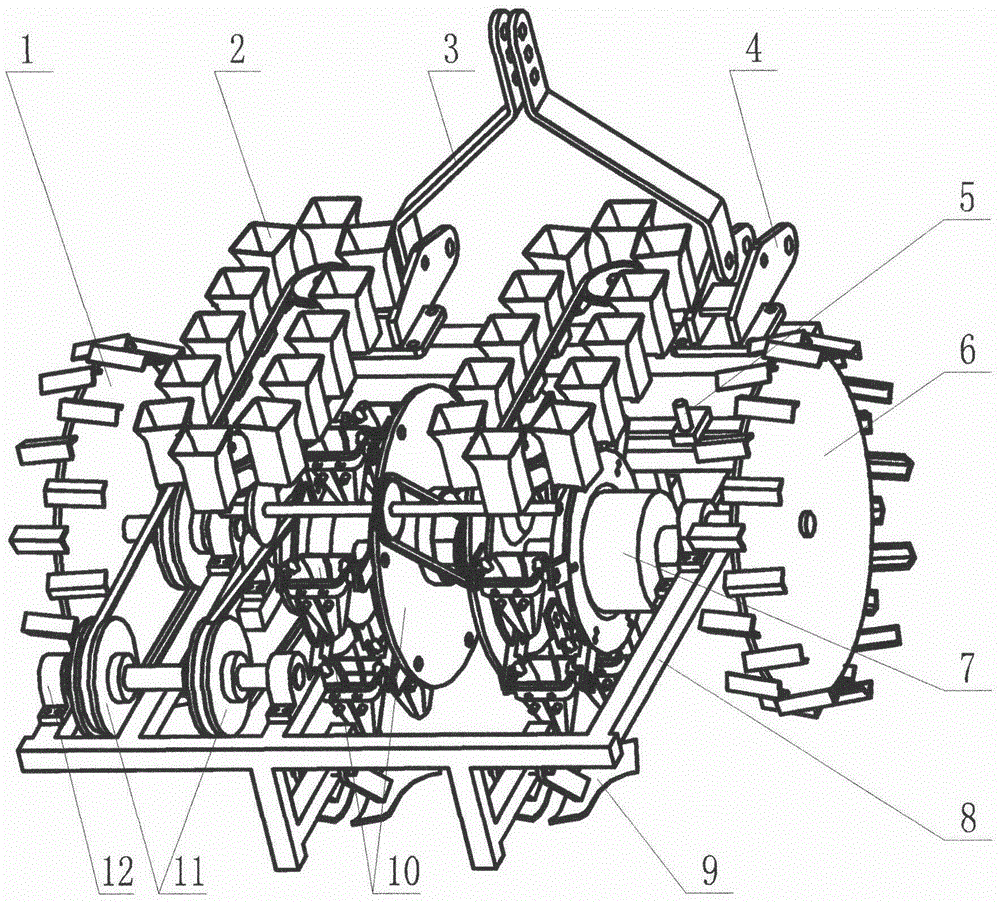

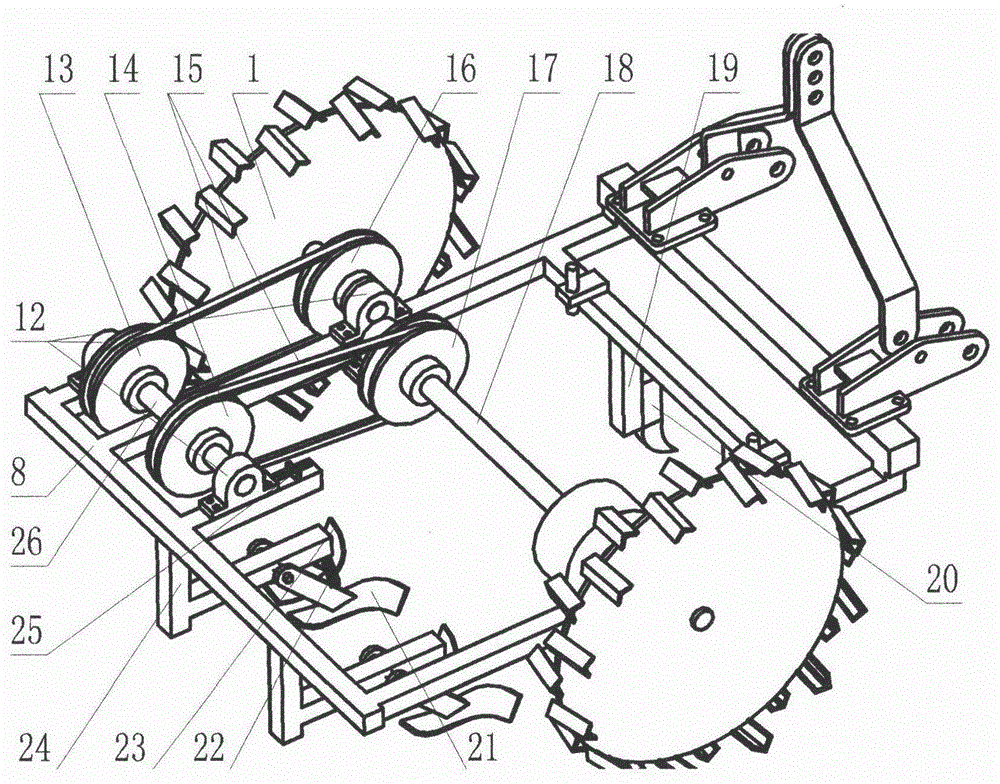

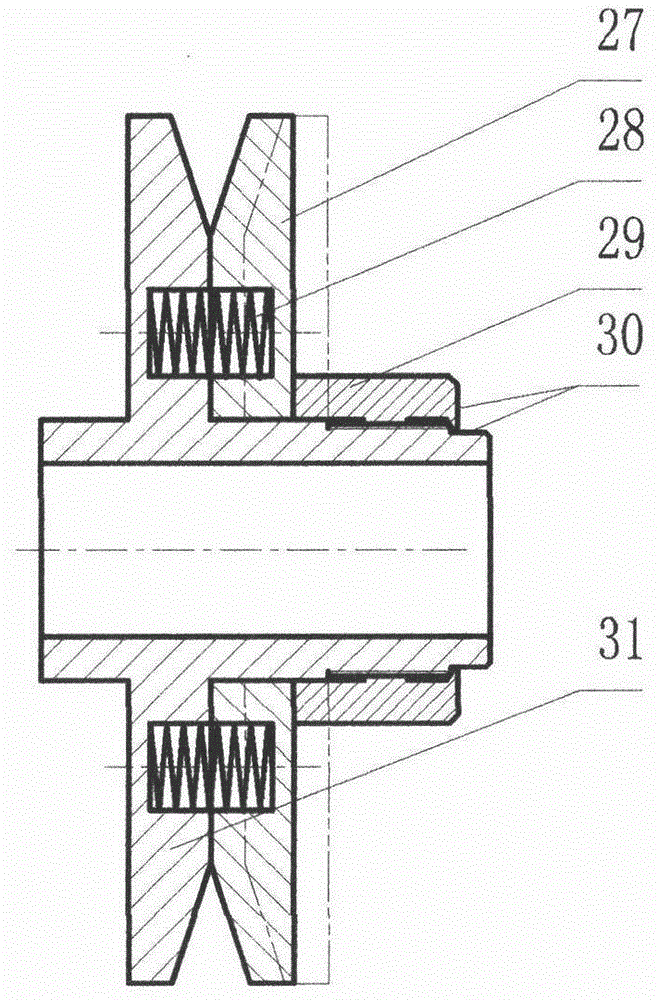

[0031] Such as Figure 1-7 As shown, with the driving of the walking driving wheel (1), the planting work of stable fixed-distance crop seedlings is realized, and a hydraulic motor (7) is added to provide the planting force at the same time, to reduce the working resistance of the driving wheel and prevent the driving wheel from Due to the sliding force of working resistance, the change of plant distance is affected. In view of the different agronomic requirements of different crop seedlings on row spacing and plant spacing, by adjusting the adjusting nut (29) of the adjustable diameter pulley set, the distance between the fixed wheel (31) and the adjusting wheel (27) is adjusted to realize the change of the transmission ratio and realize The agronomic requirements of different crop seedlings for row spacing; by adjusting the distance between a pair of seedling planting mechanisms, the agronomic requirements of different crop seedlings for row spacing are realized. Through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com