Cleaner unit and gas extraction system

A gas extraction and gas technology, applied in the field of slag remover and gas extraction system, can solve the problems of blocking the gas extraction pipe network, affecting the extraction efficiency of the gas extraction system, etc., achieving simple structure and improving gas extraction. Reliable effect of efficiency and slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

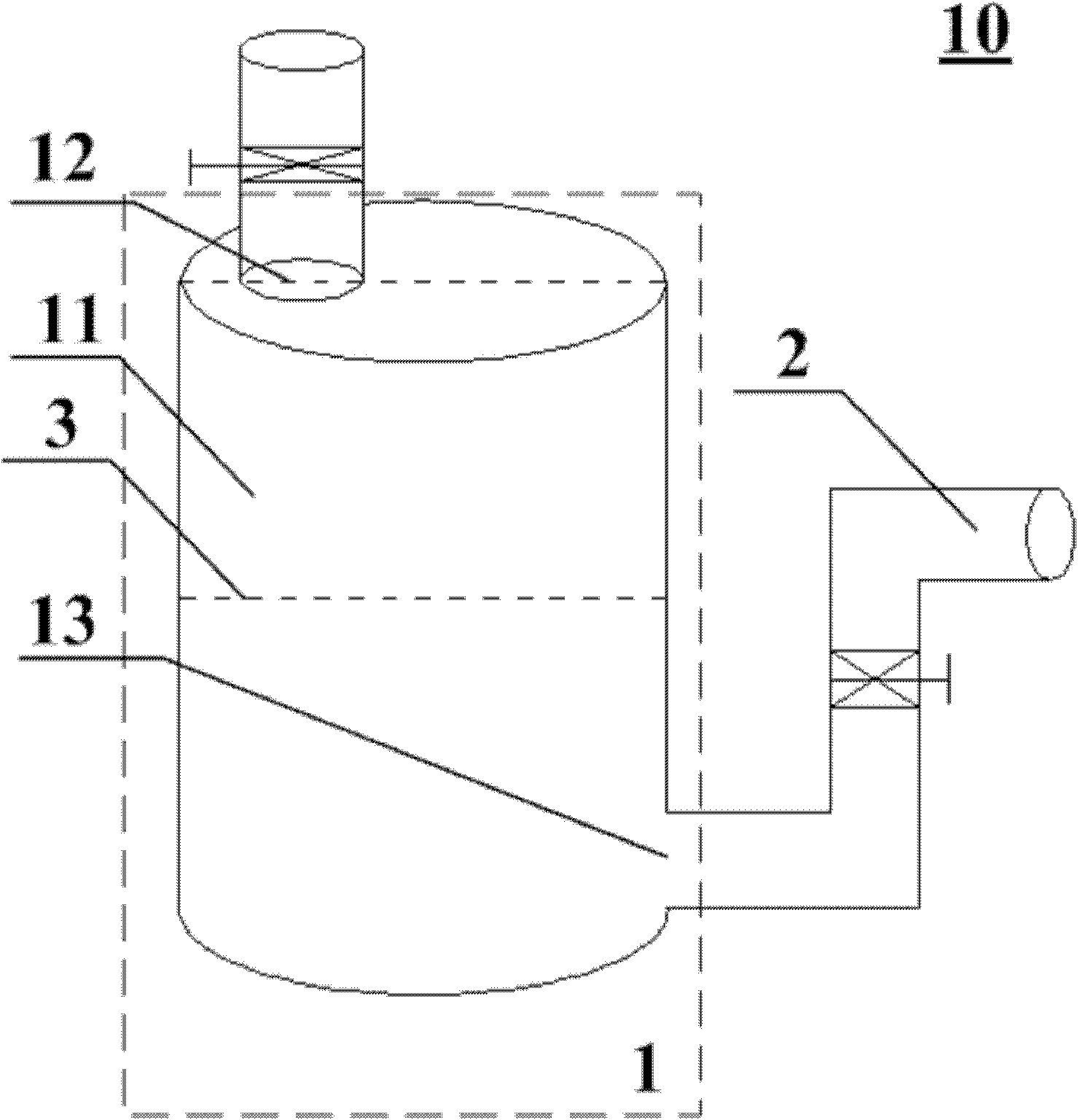

[0035] figure 1 It is a schematic diagram of the slag remover provided by Embodiment 1 of the present invention. Embodiment 1 of the present invention provides a slag remover 10 , which includes a filter device 1 and a connecting pipe 2 . The filter device 1 has a closed cavity 11 capable of accommodating liquid, and an outlet 12 is opened on the upper part of the closed cavity 11, and the outlet 12 is used to output filtered gas; an inlet 13 is opened on the lower part of the closed cavity 11, and the inlet 13 is used to input the gas to be filtered; the height of the connecting pipe 2 is greater than the liquid level 3 of the liquid contained in the closed cavity 11, one end of the connecting pipe 2 is sealed with the inlet 13, and the other end is used for the output port of the blowout preventer Sealed connection.

[0036] The slag remover provided in Embodiment 1 of the present invention has a filter device and a connecting pipe, and the connecting pipe can transport th...

Embodiment 2

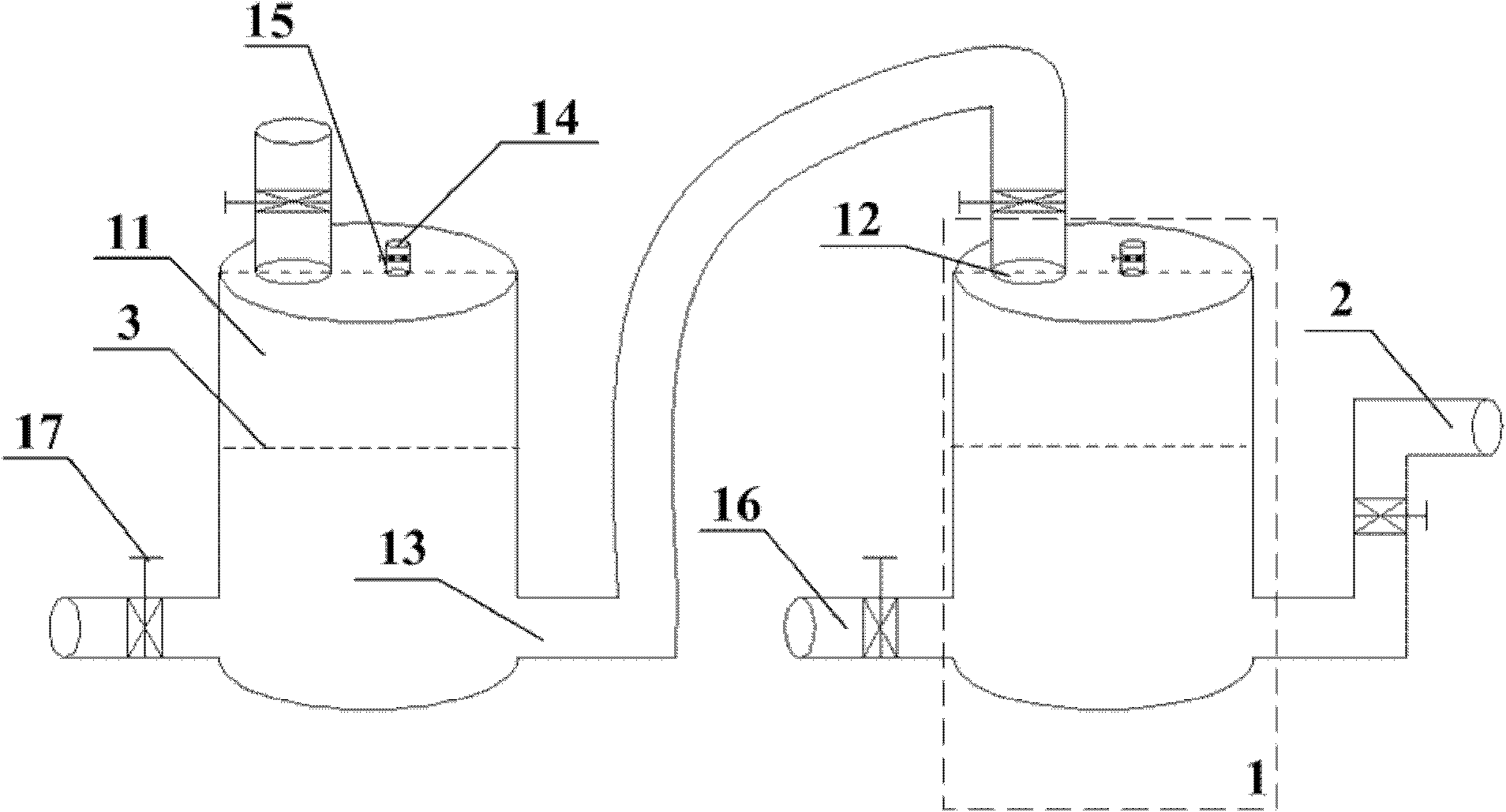

[0038] figure 2 Schematic diagram of the slag remover provided for the second embodiment of the present invention. Embodiment 2 of the present invention is based on the technical solution of Embodiment 1. Preferably, the number of filter devices 1 is at least two, each filter device 1 is sealed in sequence, and the outlet 12 and inlet of adjacent filter devices 1 13 connected to each other. That is, the inlet 13 of the first filter device 1 is connected to one end of the connecting pipe 2 for inputting the gas to be filtered into the filter device 1, and the outlet 12 of the first filter device 1 is connected to the inlet 13 of the second filter device 1 , the outlet 12 of the second filtering device 1 is connected with the inlet 13 of the third filtering device 1, and so on.

[0039] Setting multiple filtering devices can improve the filtering effect.

[0040] Further, the upper end of the closed cavity 11 is provided with a liquid inlet pipe 14, and the liquid inlet pipe...

Embodiment 3

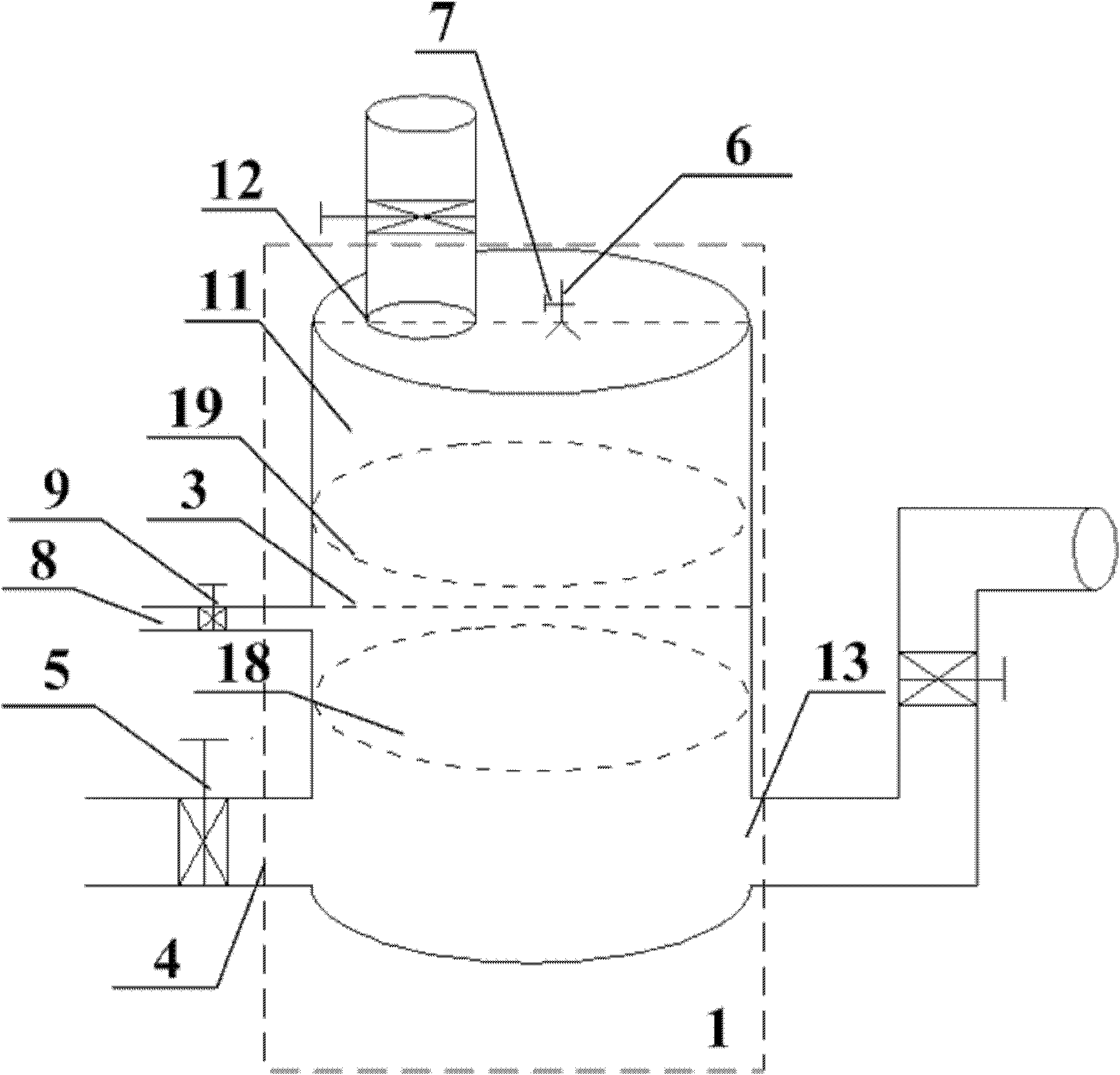

[0044] image 3 It is a schematic diagram of the slag remover provided by Embodiment 3 of the present invention. Embodiment 3 of the present invention is based on the technical solution of Embodiment 1. It is preferred that the filter device 1 further includes a first filter screen 18, which is fixedly arranged on the inner wall of the closed cavity 11, intercepting In the gas flow path, and the liquid level 3 of the liquid is higher than the installation position of the first filter 18 .

[0045] Setting the first filter screen and making the liquid level of the liquid higher than the installation position of the first filter screen can effectively prevent coal dust in the solution from being suspended on the surface of the solution.

[0046] Further, the filter device also includes a second filter screen 19, which is fixedly arranged on the inner wall of the closed cavity 11, intercepted in the flow path of the gas laterally, and the liquid level 3 of the liquid is lower th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap