Softened veneer and manufacturing process thereof

A production process and veneer technology, which is applied in the direction of manufacturing tools, wood layered products, wood processing appliances, etc., can solve the problems of limiting the application range of wood products, small bending range, and poor practicability, etc., to achieve strong practicability, The effect of improving product grade and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present invention is further described.

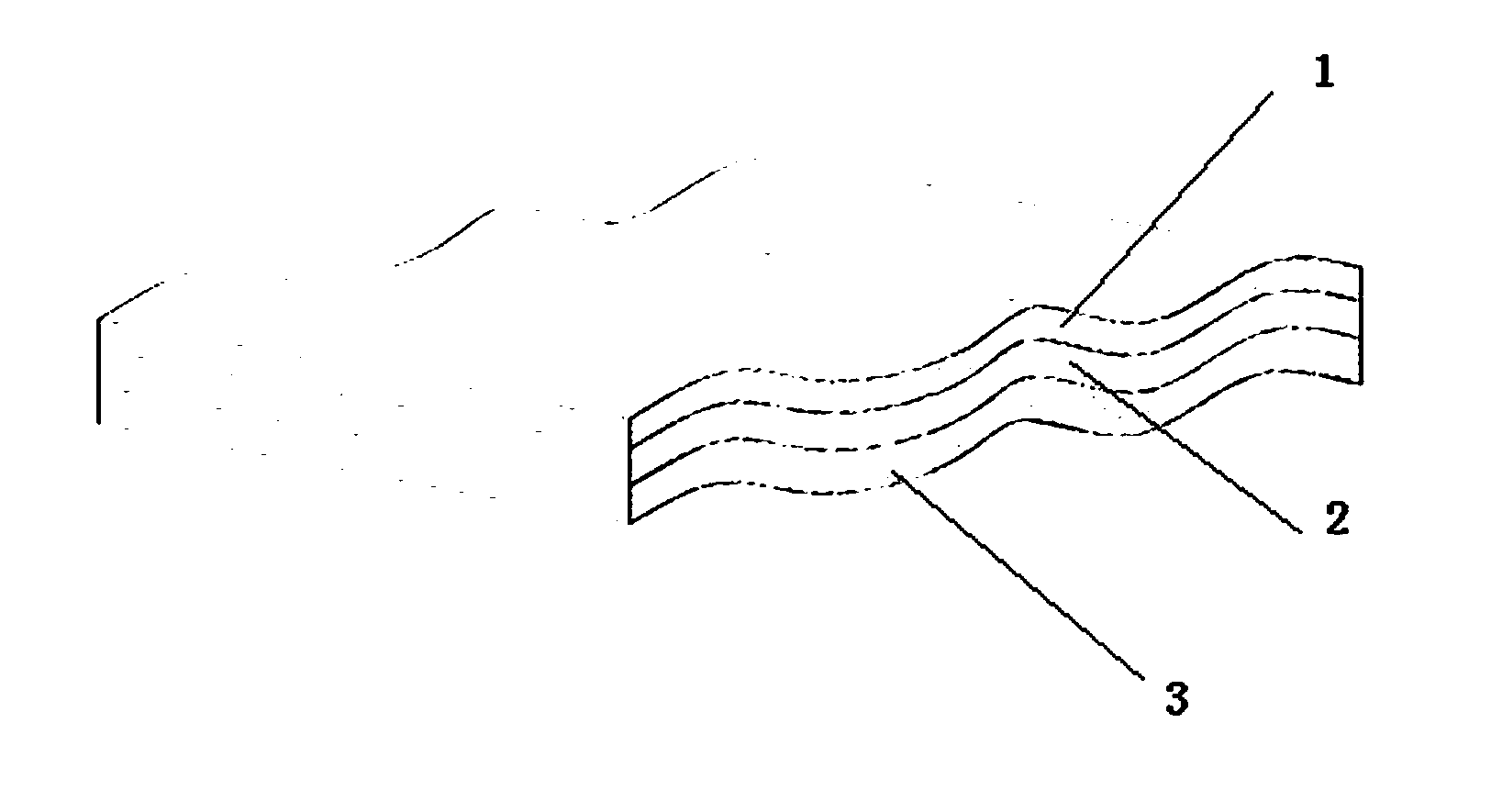

[0021] Such as figure 1 As shown, a softened veneer comprises a cork layer I1 and a cork layer II3, and a solid glue layer 2 is fixed between the cork layer I1 and the cork layer II3, and the solid glue layer 2 binds the cork layer The above-mentioned cork layer I1 and cork layer II3 are connected into a softened veneer whole.

[0022] The thickness of the cork layer I1 and the cork layer II3 is 0.2-0.5 cm; the thickness of the solid glue layer 2 is 0.1-0.2 cm.

[0023] A kind of manufacture craft of described softening veneer, comprises the following steps:

[0024] 1. Material selection, choose wood without cracks, cut it into thin plates with a thickness of 0.2-0.5 cm, and prepare materials for cork layer Ⅰ1 and cork layer Ⅱ3;

[0025] 2. Prepare solid glue, use ethylene propylene as the main raw material to prepare solid glue, and then evenly coat it on the underlying cork layer Ⅰ1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com