Automatic cage curtain door

A technology of can curtain door and curtain door, which is used in transportation and packaging, lifting equipment in mines, etc., can solve the problems of endangering the life, health and safety of workers, high labor intensity, and low safety factor, and achieves simple structure and lightening. Labor intensity and the effect of improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

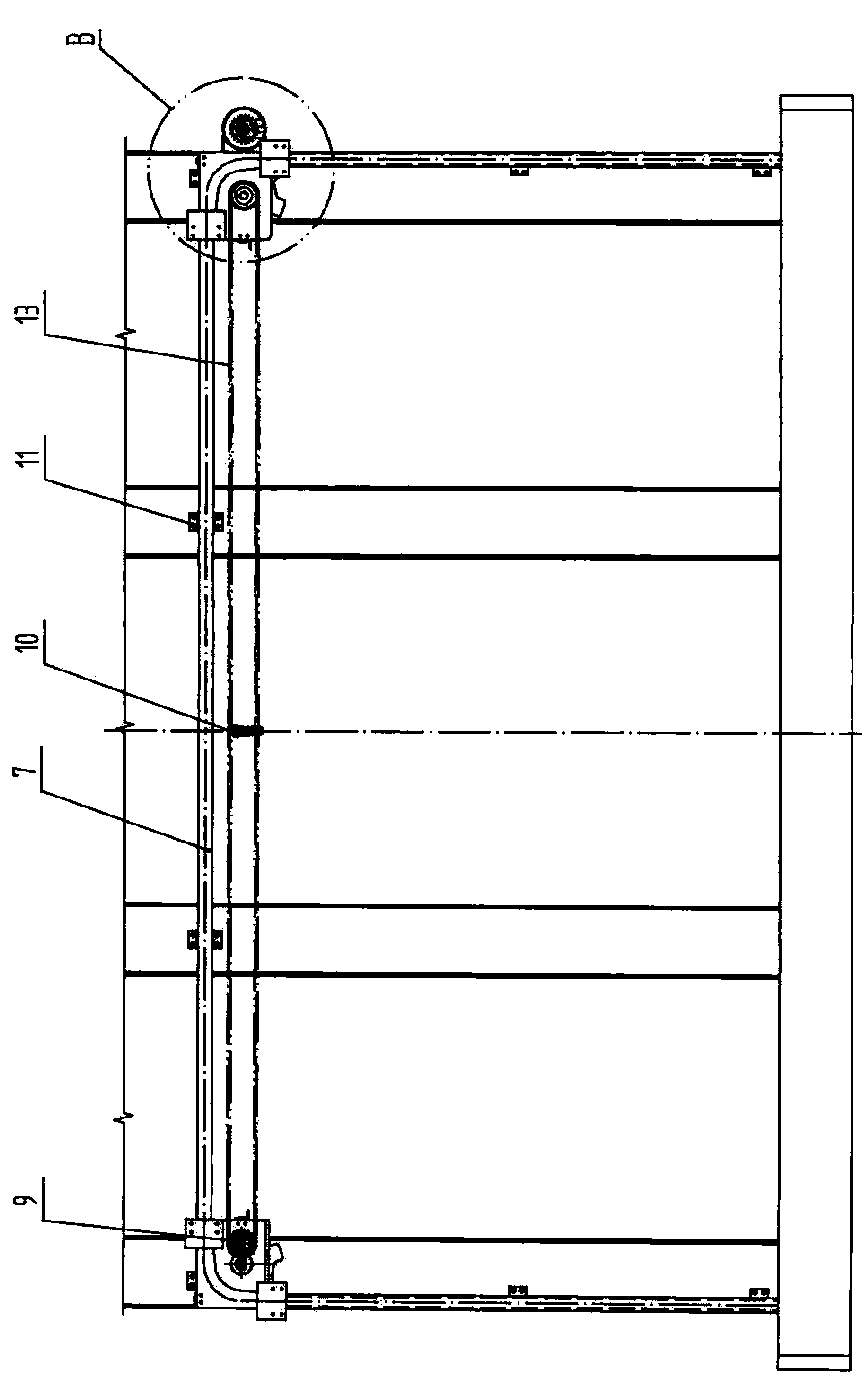

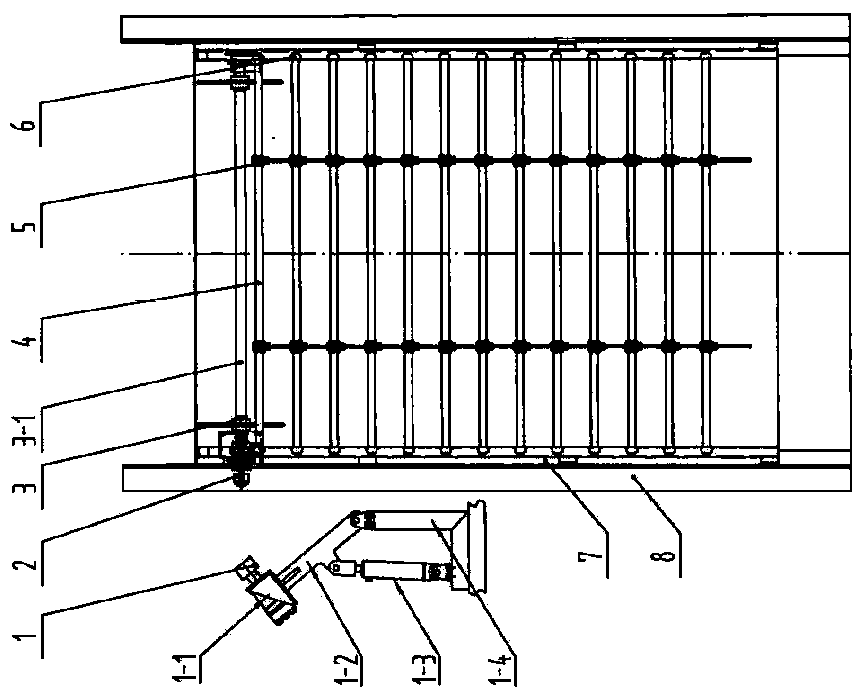

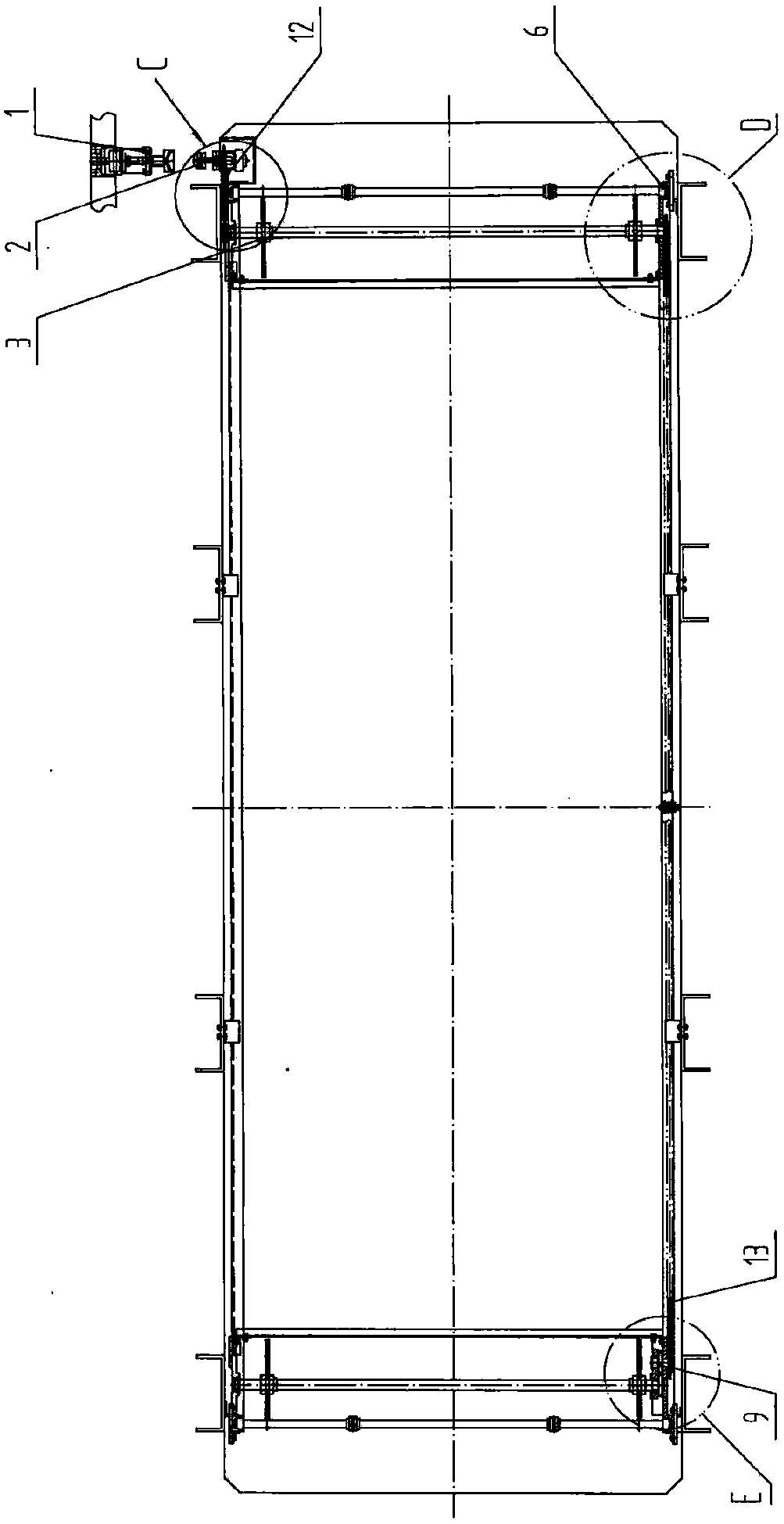

[0027] An automatic tank curtain door as shown in the accompanying drawings, it includes a curtain door device, a driving device 1 and a transmission device 2. The curtain door section 4, the curtain door track 7 is fixed on both sides inside the cage 8, the curtain door track 7 extends vertically from the lower end of the entrance and exit of the cage 8 to the upper part of the cage 8, and transitions to the upper space of the cage 8 through an arc A horizontal track is formed, and the plurality of curtain door sections 4 are hinged together through the curtain door section ring buckles 5. Section guide wheels 6 are installed at both ends of each of the curtain door section 4, and the section guide wheels 6 extend into the In the described curtain door track 7; The top of described cage 8 entrances and exits is equipped with dial shaft 3-1, is fixed with two dial wheels 3 on the dial shaft 3-1, is evenly made on the outer circle of dial wheel 3 with energy Pull the fixed-pitc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com