Method for solving cracking problem during sintering of ceramic concentric spheres

A technology of ceramic concentric balls and sintering method, applied in the field of handicraft manufacturing, can solve the problems of easy cracking of concentric balls when sintered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

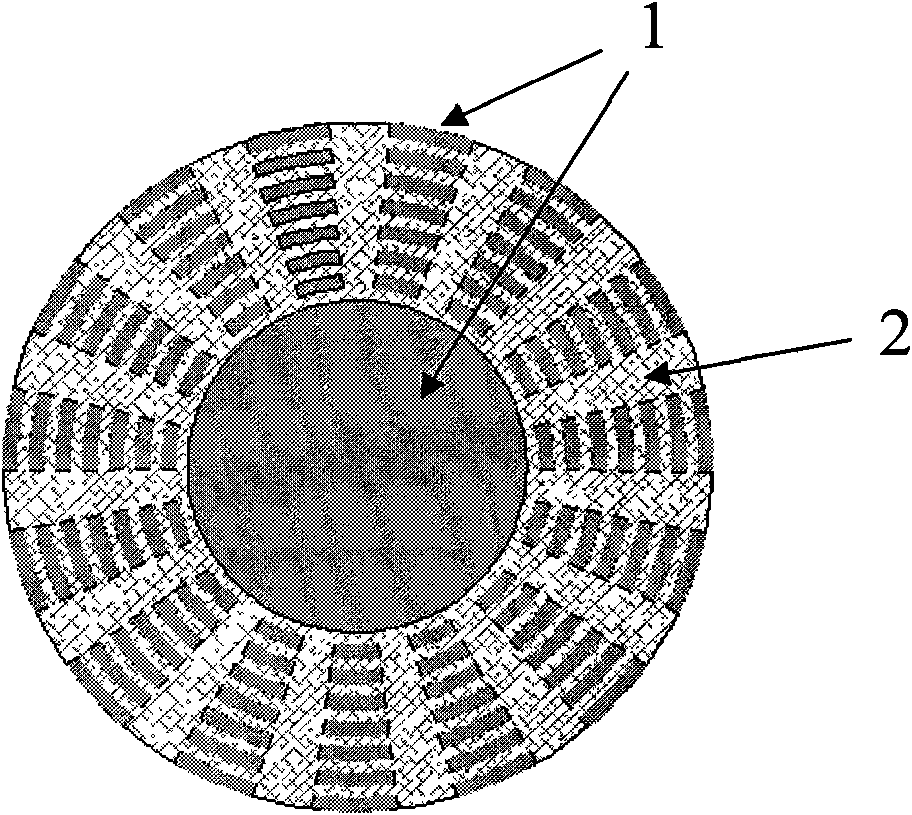

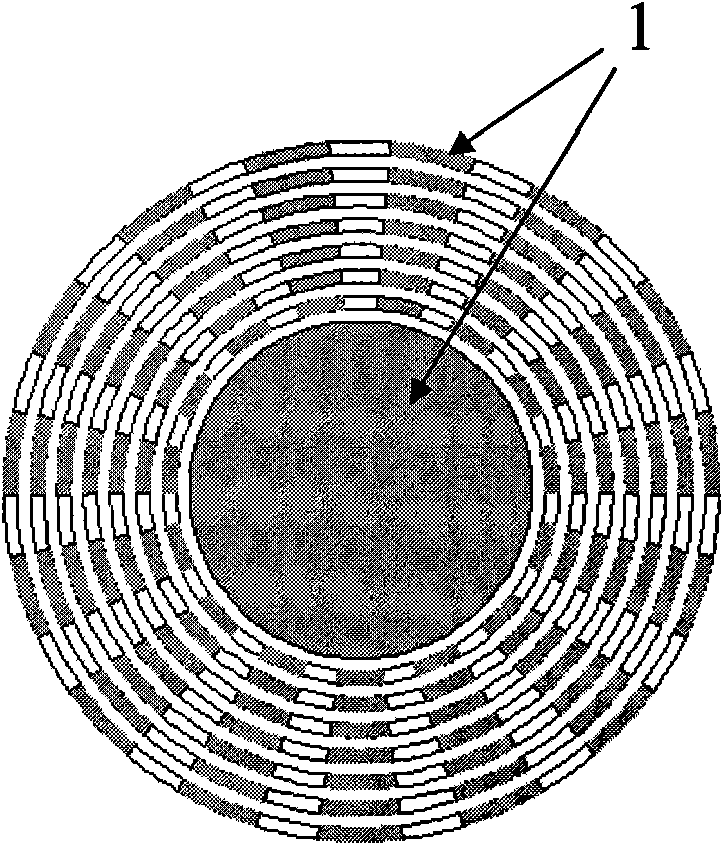

[0015] As shown in the figure, the present invention discloses a method for sintering ceramic concentric spheres, comprising the following steps:

[0016] Step 1, measuring the shrinkage rate of the blank used to make the ceramic concentric sphere after sintering;

[0017] Step 2, according to the sintering shrinkage rate of the measured ceramic blank, test to determine the proportion of various materials of the isolation layer, these materials include high temperature resistant materials such as alumina fine powder, sawdust or other organic material powder, adhesive, water or other solvents;

[0018] Step 3, prepare the isolation layer material according to the proportion and fully mix and knead it to make it a plastic blank like a ceramic green body;

[0019] Step 4, use the isolation layer blank made in the previous step for the production of ceramic concentric spheres: after the hollowed out carving is completed on each layer of the ceramic concentric sphere 1 as shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com