Composite type reactive dye composition and dyeing method by using composition

A reactive dye, composite technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

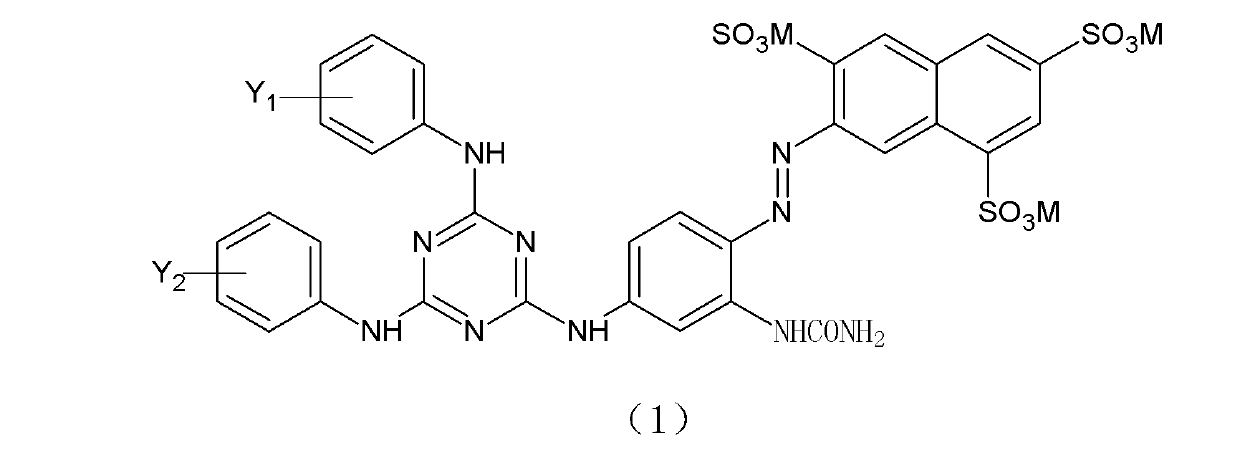

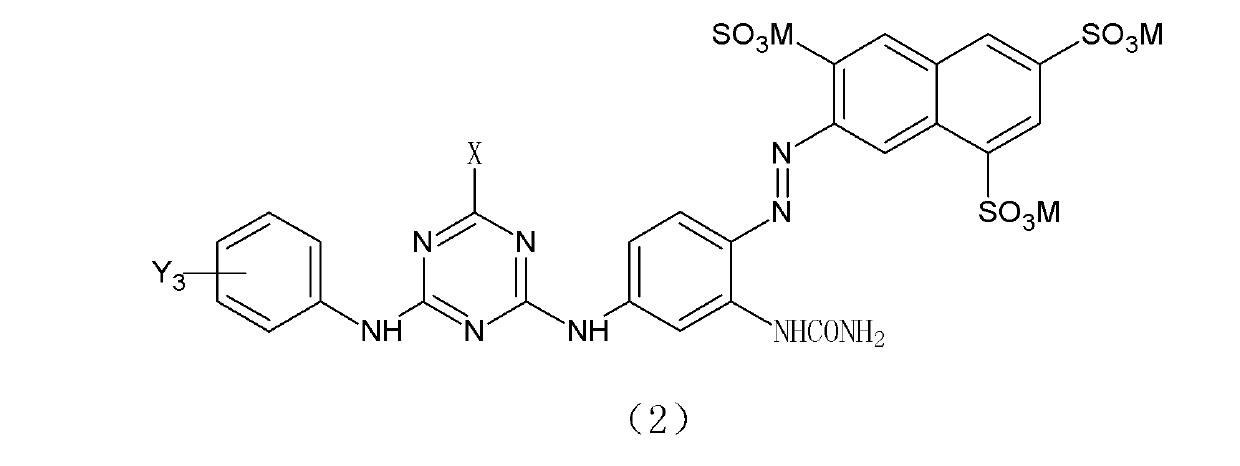

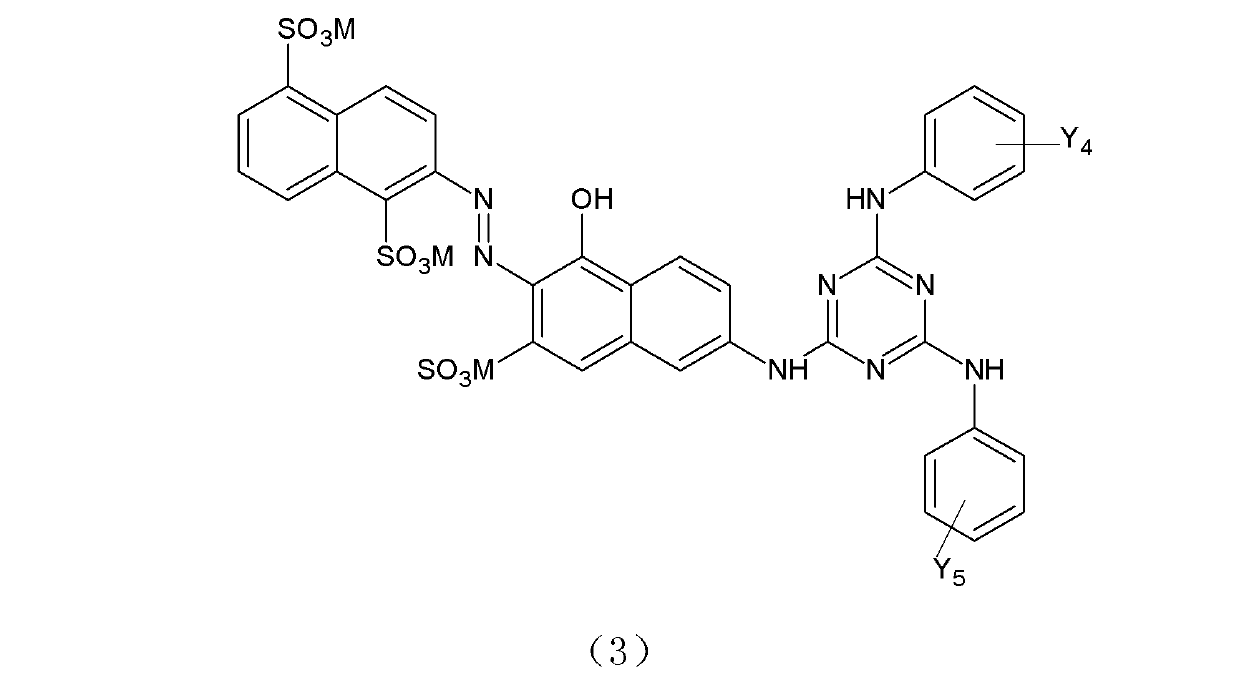

Image

Examples

Embodiment

[0059] According to the superior application performance and other characteristics, each color formula is screened out, and the specific ratio is shown in Table 1.

[0060] serial number

color

Formula ratio

1

yellow

Formula (2) 86g, formula (4) 1g, additive 13g

2

yellow

Formula (1) 32g, formula (2) 55g, formula (4) 2g, additive 11g

3

yellow

Formula (1) 34g, formula (2) 50g, formula (3) 5g, formula (4) 1g, additive 10g

4

red

Formula (6) 42g, formula (7) 56g, formula (8) 1g, additive 1g

5

red

Formula (5) 10g, formula (6) 37g, formula (7) 42g, formula (8) 2g, additive 9g

6

red

Formula (5) 20g, formula (6) 30g, formula (7) 30g, formula (8) 10g, additive 10g

7

blue

Formula (10) 43g, formula (11) 23g, formula (6) 8g, additives 26g

8

blue

Formula (9) 20g, formula (10) 60g, formula (11) 10g, additive 10g

9

blue

Formula (9) 10g, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com