Device and method for silkworm cocoon vacuum penetration treatment

A technology of vacuum infiltration and treatment device, which is applied in mechanical treatment, fiber treatment, silk fiber production and other directions, can solve the problems of inapplicability of automatic silk reeling machine, high labor intensity of staff, increase in production cost, etc., and achieves simple and easy operation. , the effect of saving manpower and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

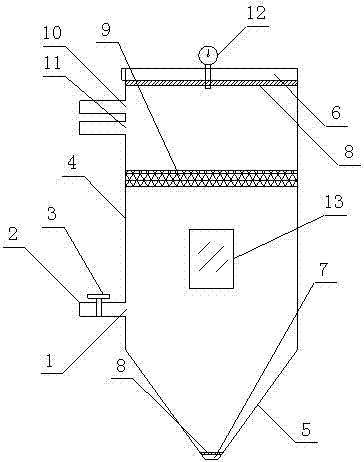

[0032] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0033] A vacuum infiltration treatment device for silkworm cocoons, comprising an operating table, a water storage tank, a vacuum tank, a cocoon tank, and an inner cover 9 used in conjunction with the vacuum tank. The inner cover 9 is provided with plum blossom eyes. The vacuum tank and the dry cocoon bag are placed on the operating table, and the water inlet 1 of the vacuum tank is connected with the water storage tank through the water inlet pipe 2, and the water inlet pipe 2 is provided with a pool water valve 3. The lower port of the vacuum tank communicates with the cocoon pool.

[0034] Such as figure 1 As shown, the vacuum tank is composed of an upper cylindrical tank body 4 with a height of 800 mm and a diameter of 500 mm and a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com