Magnetic ink removing machine

An ink and magnetic technology, applied in the field of magnetic ink remover, can solve the problems of poor processing effect and large energy consumption, and achieve the effect of improving effect, good processing effect and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

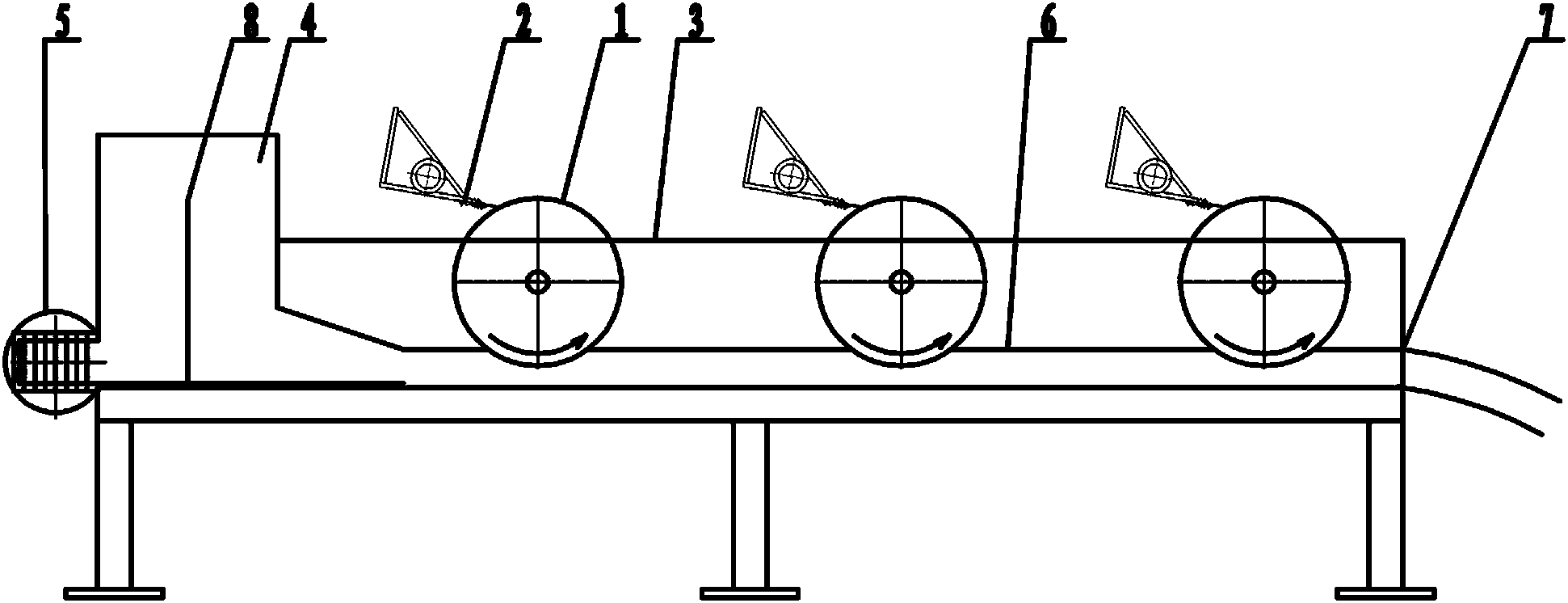

[0016] Such as figure 1 Among them, a magnetic ink removal machine, the frame 3 is provided with at least one magnetic roller 1, the magnetic roller 1 is connected with the rotary drive device, one side of the magnetic roller 1 is provided with a scraper 2 in contact with the magnetic roller 1, and the frame 3 One end is provided with a headbox 4, and the other end is provided with a pulp outlet 7. There are two or three magnetic rollers 1 used in this example. The magnetic force roller 1 is installed in the tank body of the frame 3, and the lower end of the magnetic force roller 1 is immersed in the below of the slurry liquid level 6.

[0017] The elevation of the upper end of the headbox 4 is higher than that of the frame 3 . A partition 8 is arranged inside the headbox 4 . The elevation of the upper end of the partition 8 is between the elevation of the upper end of the headbox 4 and the elevation of the upper end of the frame 3 . One side of the lower end of the headbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com