Blind hole type half axle gear

A half-shaft gear and blind hole technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problem of weakening tooth root bending strength and yield strength, overflow, and loose shaft seals, etc. problems, to achieve the effect of increasing the bending strength and yield strength and reducing the possibility of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

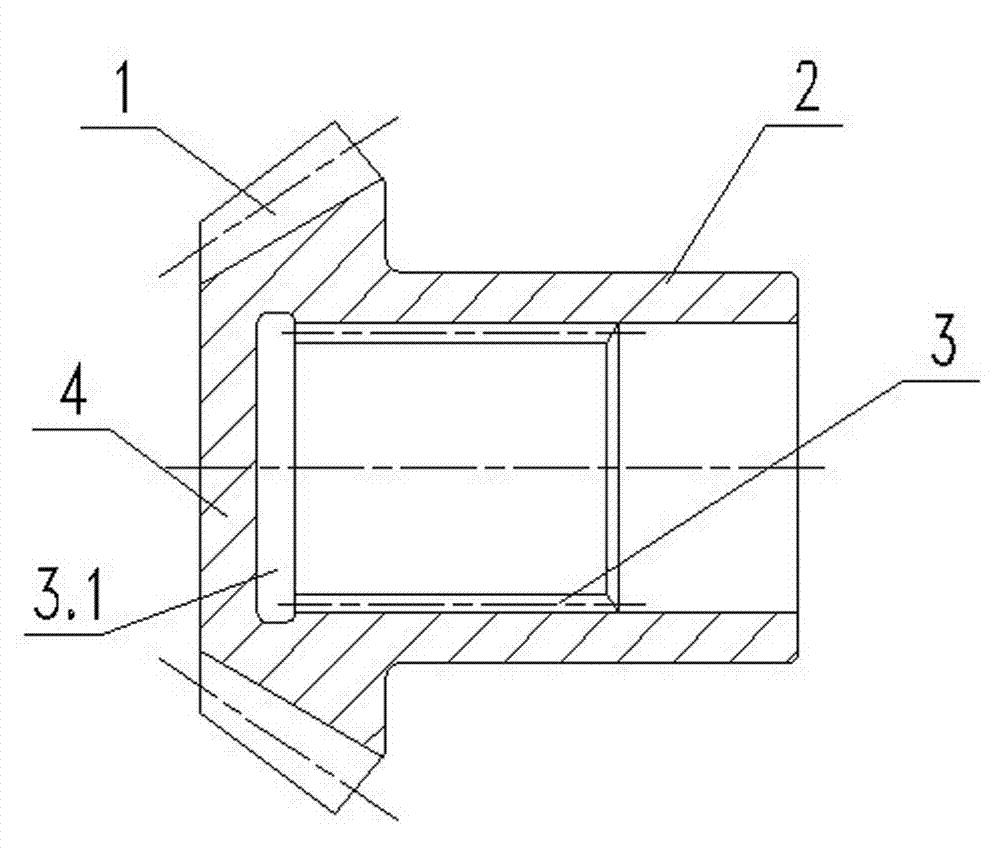

[0012] figure 1 The shown blind-hole side shaft gear consists of a bevel gear 1, a shoulder 2, an inner spline shaft hole 3 and a left end face 4. The small end of the bevel gear 1 starts from the left end face 4, and the large end of the bevel gear 1 is connected with the right shoulder 2 to form a whole. There is an undercut 3.1 between the key shaft hole 3 and the left end face 4 .

[0013] This embodiment is a side shaft gear in a DCT seven-speed automatic gearbox. Its main structural dimensions are: bevel gear 1 inner spline shaft hole 3 middle diameter Ф30mm, left end face 4 and inner spline shaft hole 3 separated by 5mm The undercut groove is 3.1, and the wall thickness of the left end face 4 is 4.2mm. Under the above-mentioned structural size conditions, the left end face 4 radially supports the small end of the bevel gear 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com