Intelligent-control non-retractable synchronous soot blower system

A soot blower, non-telescopic technology, applied in the treatment of combustion products, combustion methods, removal of solid residues, etc., can solve the problems of easy leakage of the sleeve, low soot blowing efficiency, waste of steam, etc., and reduce equipment. High usage, high soot blowing efficiency, and the effect of reducing land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

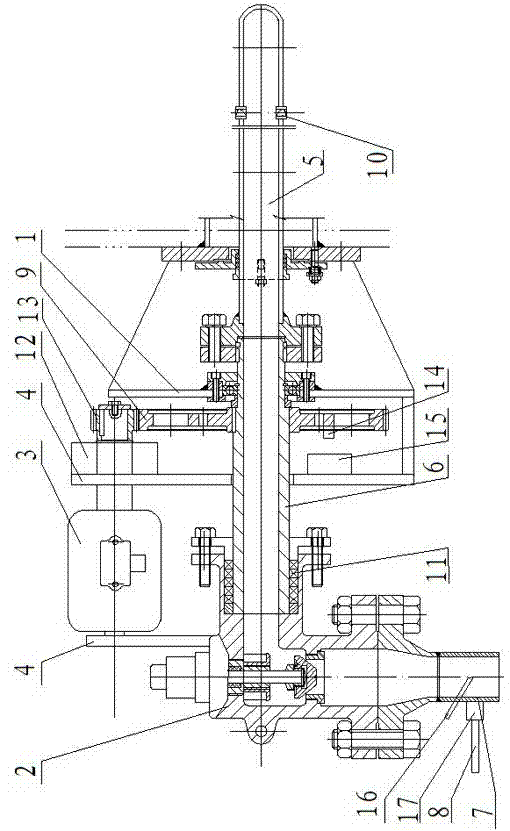

[0015] like figure 1 As shown, the present invention mainly consists of an industrial furnace connection mechanism 1, a soot blowing solenoid valve 2, a motor 3, a motor support plate 4, a soot blowing pipe 5, a soot blowing pipe connecting pipe 6, a steam connecting pipe 7, a heating pipe waste gas pipe 8 and a deceleration Device 12 is composed.

[0016] The soot blowing connecting pipe 6 is connected in the industrial furnace connecting mechanism 1, the soot blowing connecting pipe 6 is also fixedly connected with the transmission gear 9, the front end of the soot blowing connecting pipe 6 is connected with the soot blowing pipe 5, and the soot blowing pipe 5 is also opened There is a steam nozzle 10, the rear end of the soot blowing connecting pipe 6 communicates with the outlet of the soot blowing solenoid valve 2, and a sealing packing 11 is embedded in the connection between the soot blowing connecting pipe 6 and the outlet of the soot blowing solenoid valve 2.

[0...

Embodiment 2

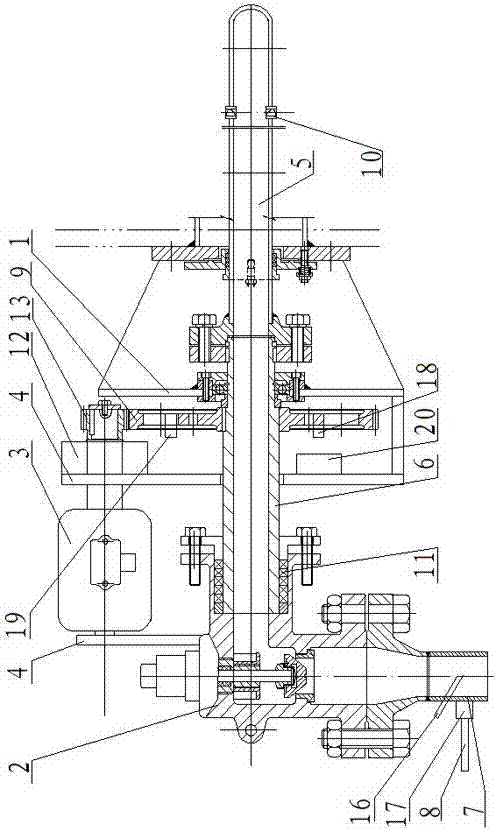

[0020] like figure 2 As shown, the structure of embodiment 2 is the same as that of embodiment 1, and the receiving device 15 of the angle measuring ruler sensing element 14 and the angle measuring ruler sensing element adopts a proximity switch, and two different angles of the transmission gear 9 are respectively equipped with a sending mechanism of the proximity switch. Terminals 18 and 19, a receiving terminal 20 of a proximity switch is installed on the industrial furnace connection mechanism 1.

[0021] Working process of the present invention:

[0022] When the system starts to blow soot, open the solenoid valve 17 of the warming pipe, the steam enters the pipeline system before the soot blower, and enters the waste steam pipe 8 of the warming pipe, and the waste steam pipe 8 of the warming pipe is connected to the waste gas recovery system of the factory system to realize recycling and achieve the goal of design. After a certain period of time, the thermocouple 16 det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com