Flow-equalizing self-stabilization air quantity measuring device

A technology of measuring device and air volume, which is applied in the direction of detecting fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effect, etc. The problem of uneven inlet air volume, etc., achieves the effect of low maintenance cost, novel structure design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

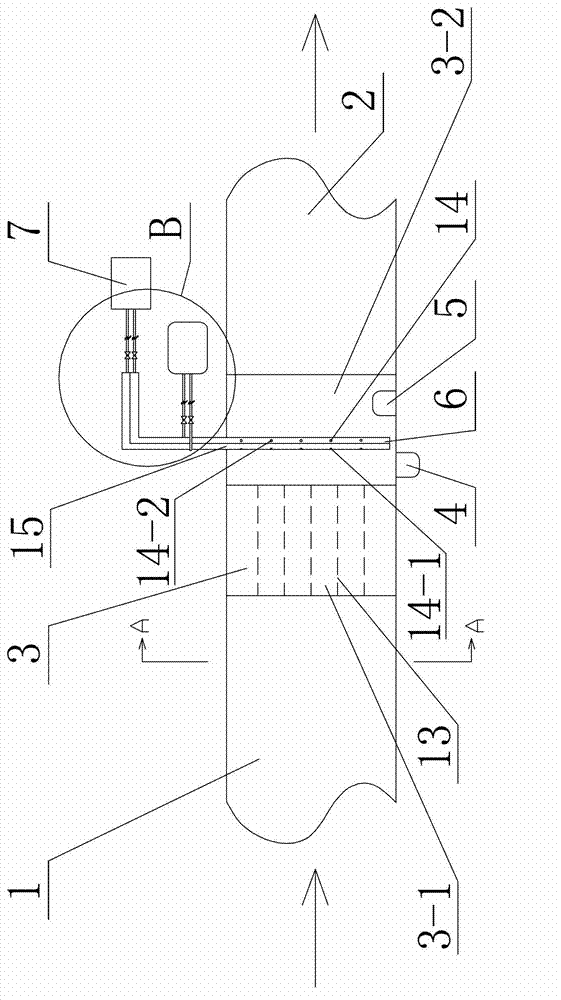

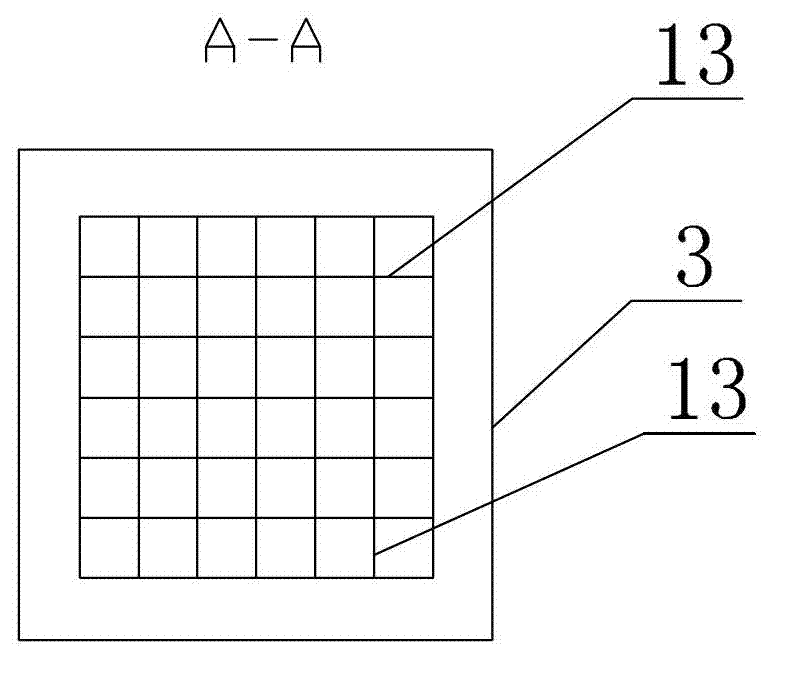

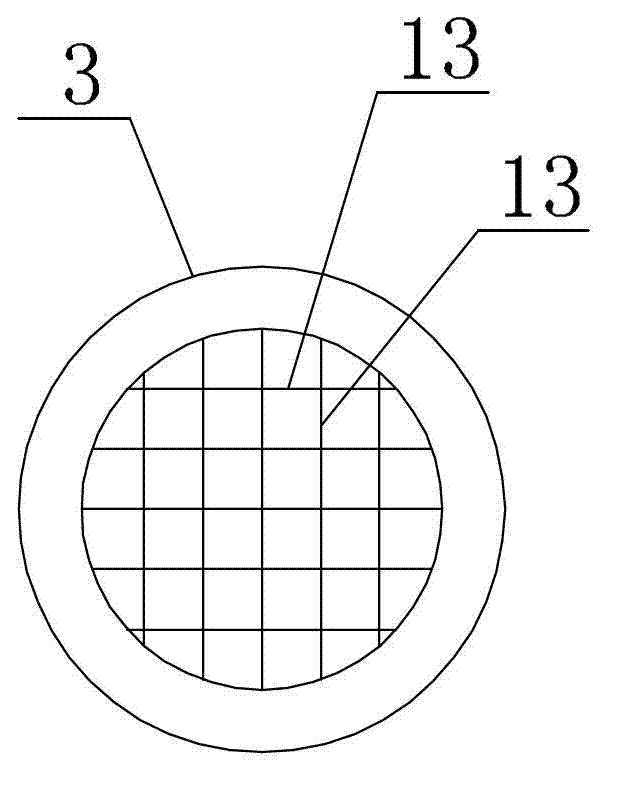

[0015] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 To illustrate this embodiment, the flow-equalizing self-stabilizing air volume measuring device described in this embodiment includes a first air passage 1, a second air passage 2, an air flow equalizer 3, a pressure transmitter 4, a temperature transmitter 5, The velocity measuring tube 6, two differential pressure tubes 9 and two cleaning air ducts 10, the first air channel 1, the air flow equalizer 3, and the second air channel 2 are arranged in a line and communicated in sequence, and the air flow equalizer The device 3 is composed of a flow equalization area 3-1 and a test area 3-2. The flow equalization area 3-1 and the test area 3-2 are connected and integrated. The flow equalization area 3-1 of the air flow equalizer 3 A plurality of intersecting spacers 13 are fixedly connected along the length direction of the air flow homogenizer, and the cross-section of the plurality ...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 2 and image 3 To describe this embodiment, the cross section of the air flow homogenizer 3 in this embodiment is rectangular or circular. According to the specific space on the ground, the air flow equalizer 3 with an appropriate shape is selected, so as to realize the purpose of the present invention more effectively. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 , figure 2 and image 3 To illustrate this embodiment, in this embodiment, a plurality of intersecting spacers 13 are connected in the flow uniforming area 3 - 1 of the air flow homogenizer 3 along the length direction of the air flow homogenizer 3 by welding. The welding method is time-saving and labor-saving, and has strong feasibility. It has been proved in practice that the connection of multiple spacers 13 in the air equalizer by welding is the most ideal connection method. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com