Dynamic performance test device for angular contact ball bearing retainer

A technology of angular contact ball bearing and test device, applied in the direction of mechanical bearing testing, etc., to achieve the effect of fast response, reliable measurement and wide measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below in conjunction with specific embodiments.

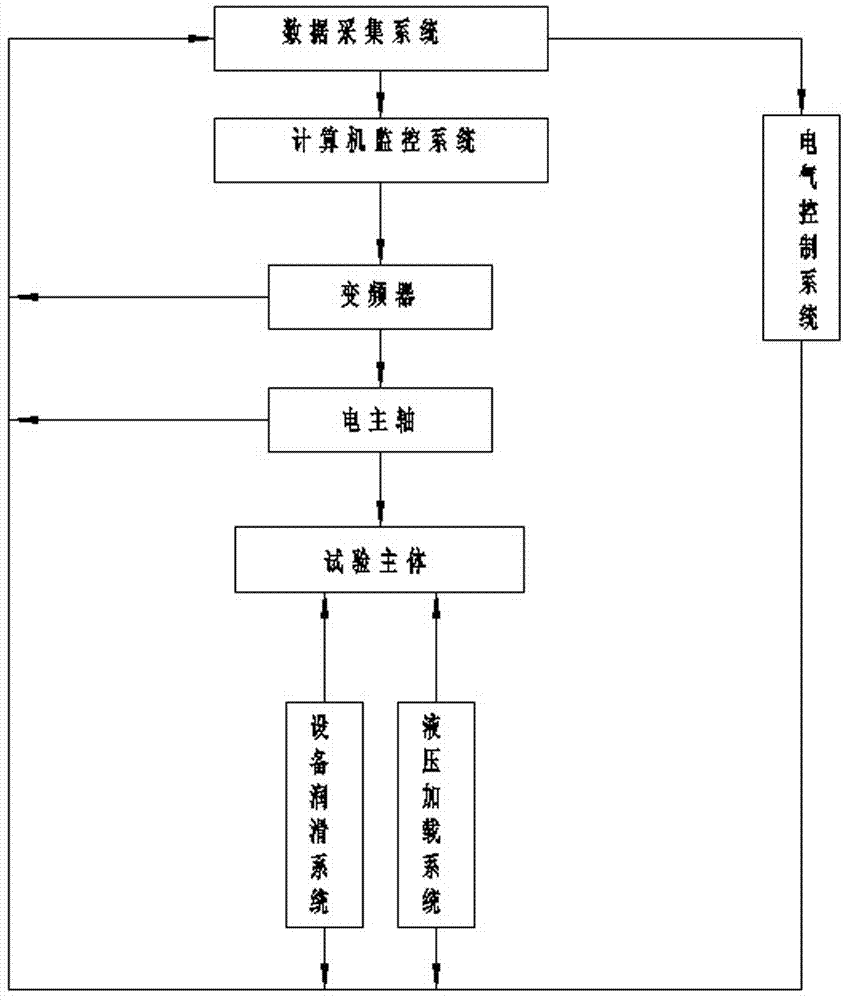

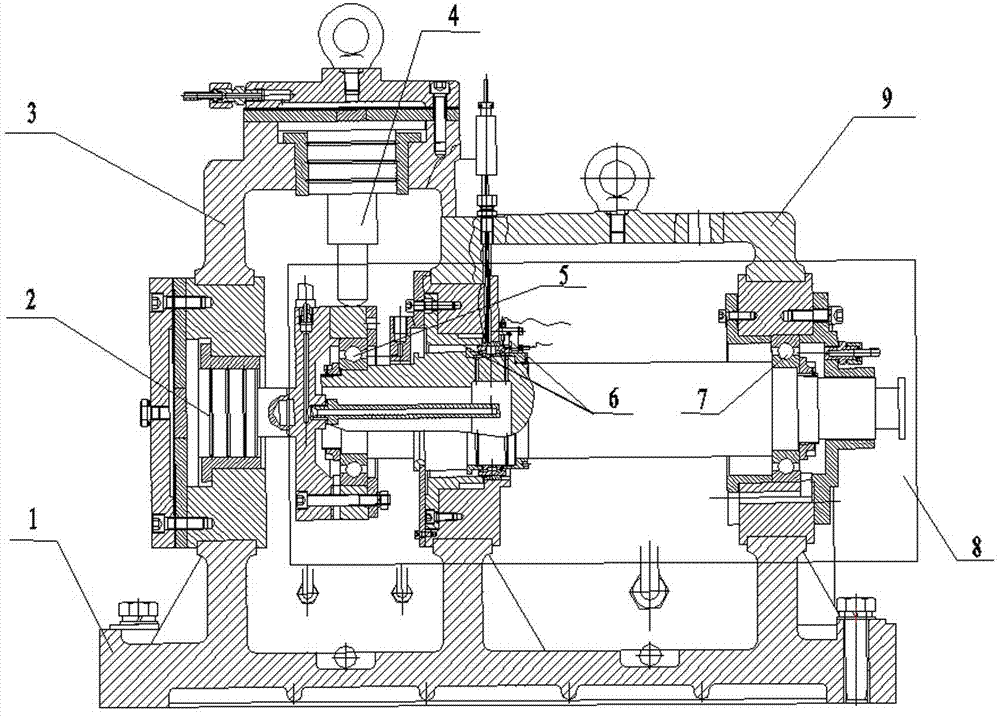

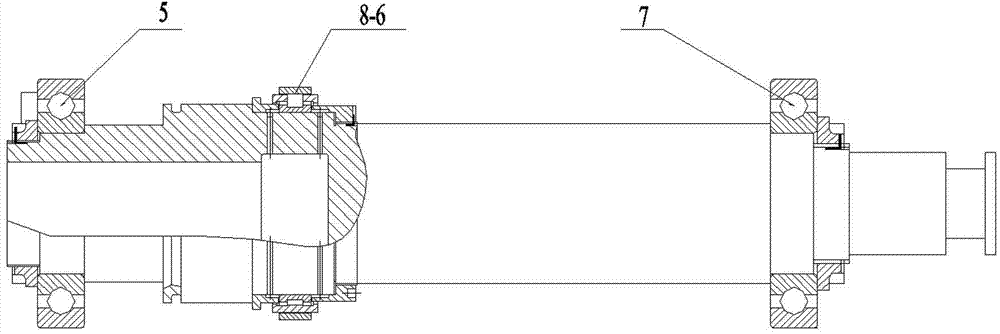

[0032] A dynamic performance test device for an angular contact ball bearing cage, including a test body, an electric spindle, a frequency converter, a hydraulic loading system, a computer monitoring system, and a data acquisition system. The electric spindle and the hydraulic loading system are respectively connected to the test body, and the frequency converter and The electric spindle is connected, the electric spindle provides power for the test main body, and the hydraulic loading system provides the test load for the test main body. After the hydraulic loading system is loaded, the signal measured by the measuring device on the test main body and the test parameters of the electric spindle and the frequency converter are respectively input to the data acquisition system, the signal output terminal of the data acquisition system is input to the computer monitoring syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com