Object surface defect detection method and apparatus based on linear array CCD

A technology for defect detection and object surface, which is applied in the direction of optical detection of defects/defects, etc., can solve the problems of high detection accuracy, achieve high detection accuracy, easy correction of distortion errors, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

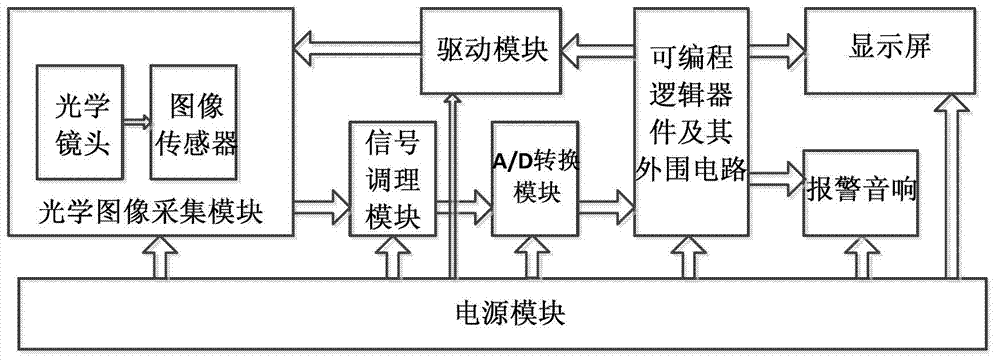

[0058] see figure 1 , the invention includes an optical image acquisition module, a signal conditioning module, an A / D conversion module, a driving module, a power supply module, a programmable logic device and peripheral circuits thereof. The programmable logic device is the core of the system, and is respectively connected with the A / D conversion module, the driving module, the power supply module and the like.

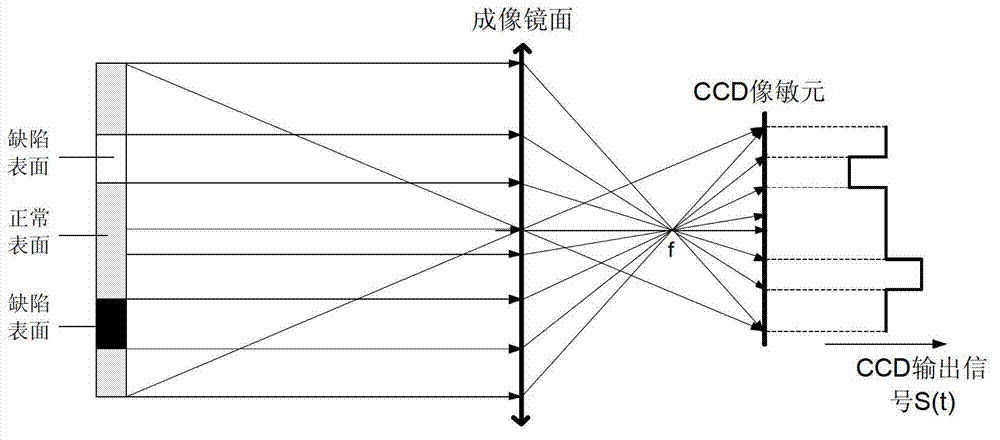

[0059] Optical image acquisition module. The module consists of a light source, an optical lens and an image sensor, and is responsible for collecting images of the surface of the object. The image sensor uses a linear array CCD. The module is powered by the power module and driven by the driver module, and the image information of the surface of the object collected by it is sent to the signal conditioning module.

[0060] Signal Conditioning Module. The module includes two parts of amplification and filtering, which is the prior art. Since the output analog s...

specific example

[0068] A specific example is as follows:

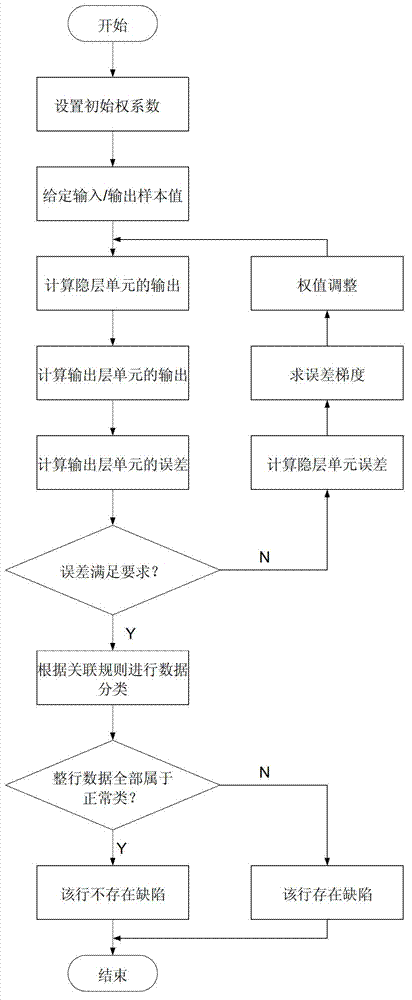

[0069] 1. The learning stage. Before classifying the data, there is a self-learning phase. In this stage, the BP neural network algorithm is used to extract the surface features of the material. Proceed as follows:

[0070] 1), data preprocessing. Before starting the training, it is necessary to normalize the collected sample data and re-encode the discrete data category attributes. First divide the corresponding voltage value in the sample by the maximum attribute value of the column, so that its input value is limited to the interval [0,1]. For discrete data category attributes, recode, and use 0 to represent "defect". Use 1 for "normal", as expected output. The normalized data is shown in Table 2. [The output voltage of the CCD is the output voltage of each pixel. Although the size of a defect is generally unlikely to be as large as one pixel, our solution is to use the method of judging whether there is a defect line by line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com