Optical laminate, polarizing plate, and display device

A technology of optical laminates and optical functional layers, applied in optics, identification devices, optical components, etc., can solve the problems of display image flashing, low density, and inability to alleviate the glare of LCD modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

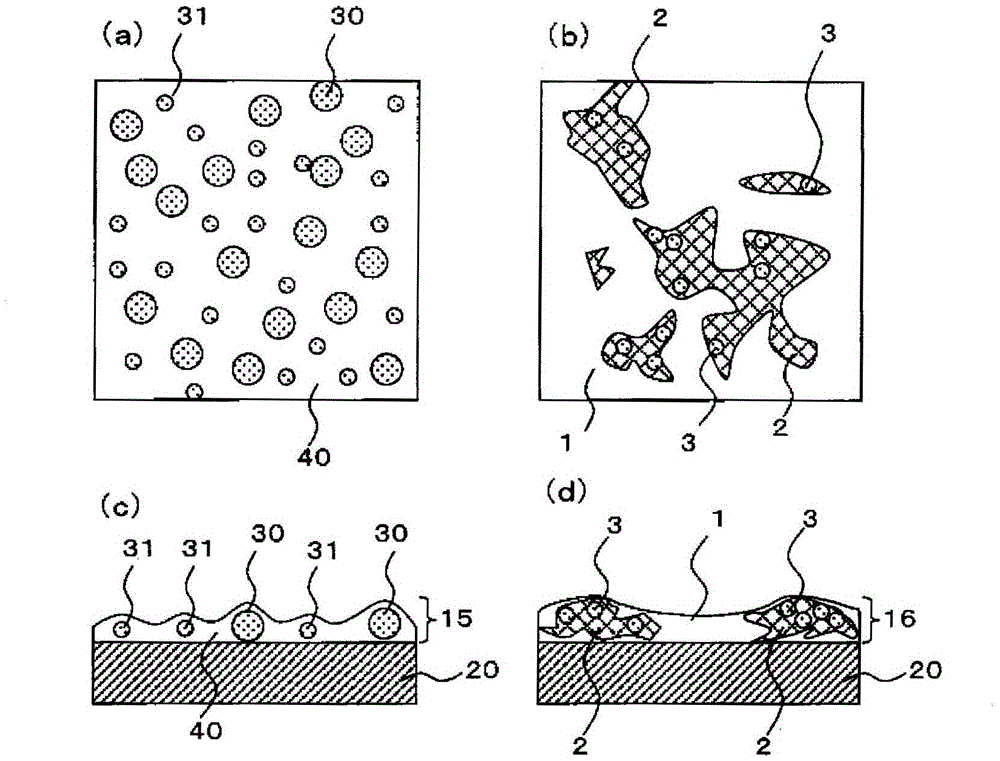

Embodiment 1

[0251] The paint for forming an optical functional layer obtained by stirring the predetermined mixture described in Table 1 with a disperser for 30 minutes was applied by roll coating (line speed: 20 m / min) to a film thickness of 60 μm and a total light transmittance of 92 % TAC (manufactured by Fuji Film Co., Ltd.; TD60UL) on one side of the transparent substrate, after pre-drying at 30-50°C for 20 seconds, drying at 100°C for 1 minute, and then irradiating ultraviolet rays (lamps) in a nitrogen atmosphere (nitrogen replacement) : Concentrating type high pressure mercury lamp, lamp output: 120W / cm, number of lamps: 4 lamps, irradiation distance: 20cm), thereby curing the coating film. Thereby, the optical laminated body of Example 1 which has an optical function layer with a thickness of 4.1 micrometers was obtained. From the results of SEM and EDS, it was confirmed that the optical functional layer constituting the obtained laminate had at least a first phase and a second p...

Embodiment 2

[0254] Except having changed the coating material for optical function layer formation into the predetermined liquid mixture described in Table 1, it carried out similarly to Example 1, and the optical laminated body of Example 2 which has the optical function layer of thickness 5.5 micrometers was obtained. From the results of SEM and EDS, it was confirmed that the optical functional layer constituting the obtained laminate had at least a first phase and a second phase, and formed a random aggregation structure.

[0255] (first invention, third invention)

Embodiment 3

[0257] Except having changed the coating material for optical function layer formation into the predetermined liquid mixture described in Table 1, it carried out similarly to Example 1, and the optical laminated body of Example 3 which has an optical function layer with a thickness of 5.5 micrometers was obtained. From the results of SEM and EDS, it was confirmed that the optical functional layer constituting the obtained laminate had at least a first phase and a second phase, and formed a random aggregation structure.

[0258] (first invention, third invention)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com