Optocoupler structure, and optocoupler structure assembly method

An assembly method and optical coupling technology, applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of complex assembly process and achieve the effect of simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

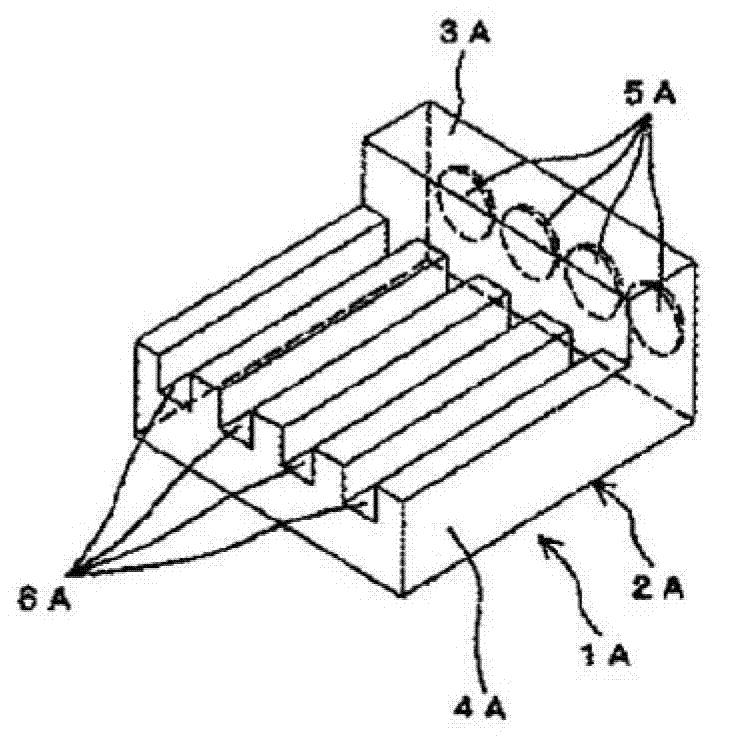

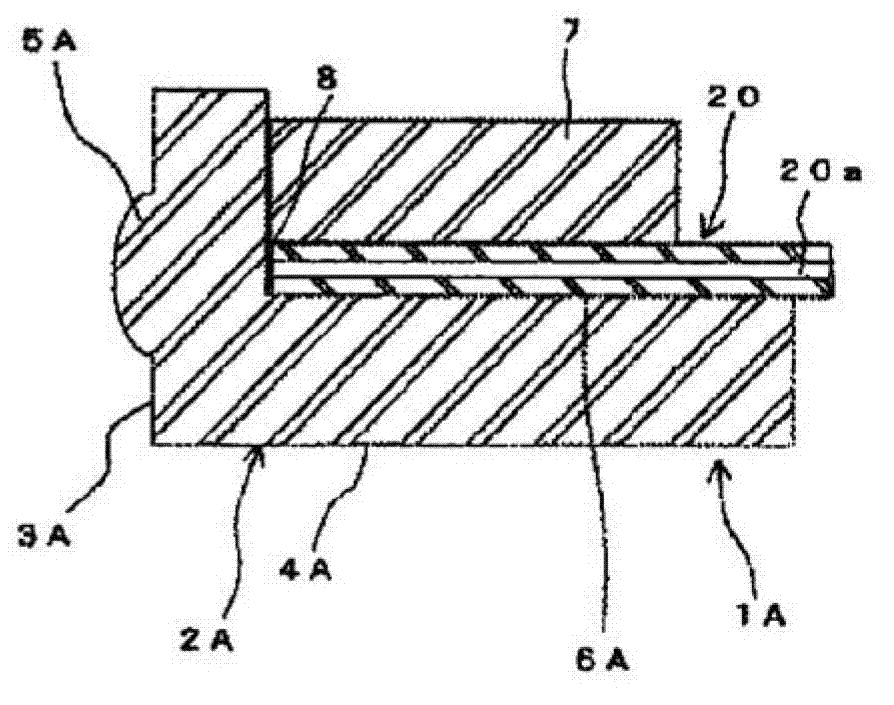

[0046] figure 2 It is a perspective view of the light coupling structure of Example 1, and FIG. 3 is a three-sided view of the light coupling structure of Example 1. FIG. Figure 3A for top view, Figure 3B for the front view, Figure 3C It is the left side view. Figure 4 yes Figure 3A The sectional view cut by the A-A line, Figure 5 yes Figure 3C A cross-sectional view taken along line BB. Figure 6 yes Figure 3A The cross-sectional view taken along the line CC is a view showing the state of optical coupling. Figure 7 Too Figure 3A The cross-sectional view taken along the line CC is a view showing another state of optical coupling.

[0047] The optical coupling configuration of Example 1 places the two optical fibers in physical contact with the lens. The optical coupling structure 10 is composed of a lens body 100 and a clamp 200 . The lens body 100 includes a lens portion 110 having lenses 111 , 112 and a fixing portion 120 . The lenses 111 and 112 shown...

Embodiment 2

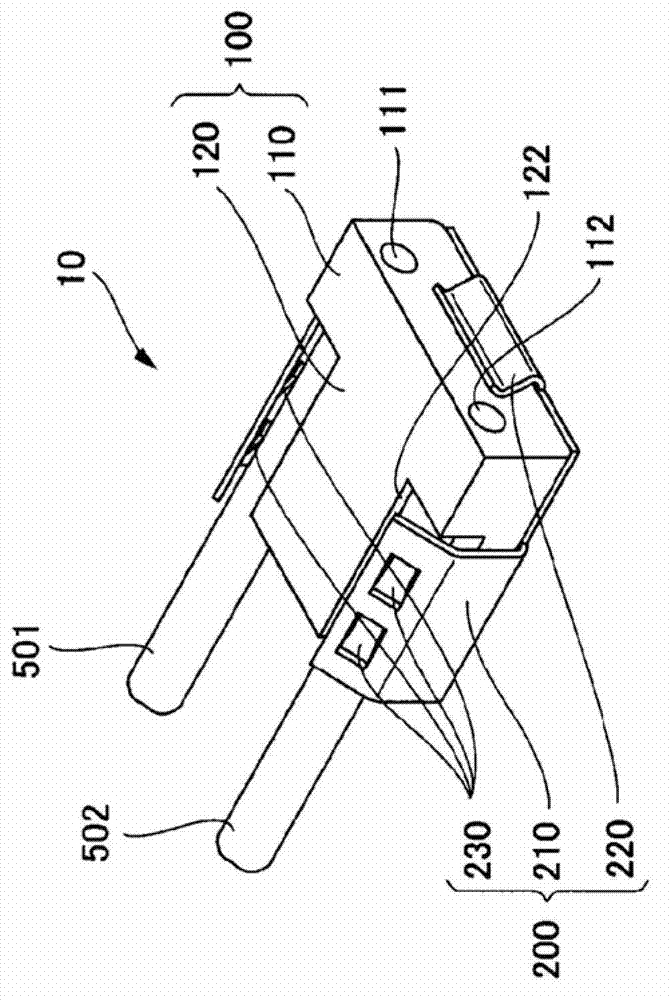

[0065] Figure 13 It is a perspective view of the light coupling structure of Example 2, and FIG. 14 is a three-sided view of the light coupling structure of Example 2. FIG. Figure 14A is a top view, Figure 14B is the front view, Figure 14C It is the left side view. Figure 15 yes Figure 14A The sectional view cut by the D-D line, Figure 16 yes Figure 14C A cross-sectional view taken along line E-E.

[0066] The optical coupling configuration of Example 2 places the two optical fibers in physical contact with the lens. The optical coupling structure 70 is composed of a lens body 700 and a clamp 800 . The lens body 700 includes a lens portion 710 having lenses 711 , 712 and a fixing portion 720 . The structures, functions, etc. of the lenses 711 and 712 are the same as those of the lenses 111 and 112 of the first embodiment, and the optical characteristics can be appropriately designed according to the type of optical coupling to be performed.

[0067] The fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com