Fixed galvanized bottle cultivation mushroom frame

A fixed, bottle planting technology, applied in horticulture, application, botany equipment and methods, etc., can solve the problems of increasing installation cost, affecting appearance, wasting manpower, etc., and achieving the effect of quick installation, saving installation time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

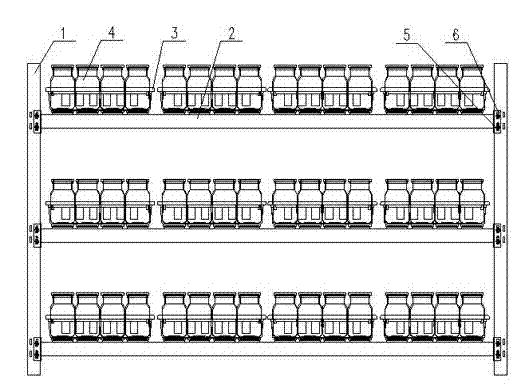

[0009] Such as figure 1 As shown, the fixed galvanized bottle mushroom planting rack includes: two columns 1, some beams 2 are arranged between the two columns 1, some brackets 3 are arranged on the beam 2, and the bottle 4 is arranged in the bracket 3, Two ends of the beam 2 are respectively provided with connecting pieces 5 , and two upright columns 1 are respectively provided with mounting holes 6 matched with the connecting pieces 5 .

[0010] The above-mentioned fixed galvanized bottle mushroom planter has a simple structure, quick installation, no welding on site, saves installation time, reduces installation cost, and is not easy to rust and looks beautiful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com