Workpiece cleaning line

A technology for cleaning lines and workpieces, applied to cleaning methods and appliances, cleaning methods using liquids, and surface pretreatment, etc., can solve problems such as increased labor intensity, workpiece cleaning, and reduced work efficiency, and achieve high work efficiency and automation High degree, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

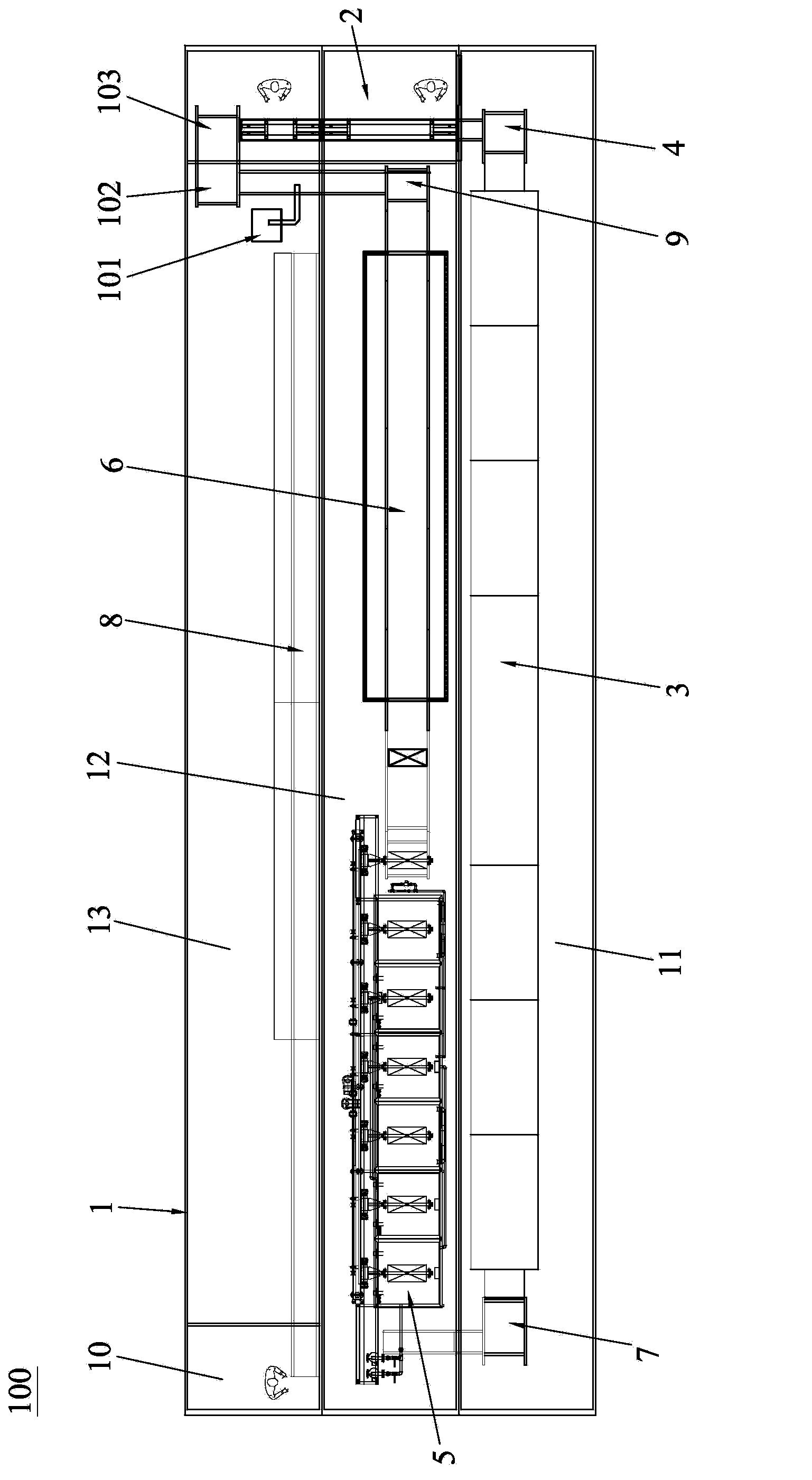

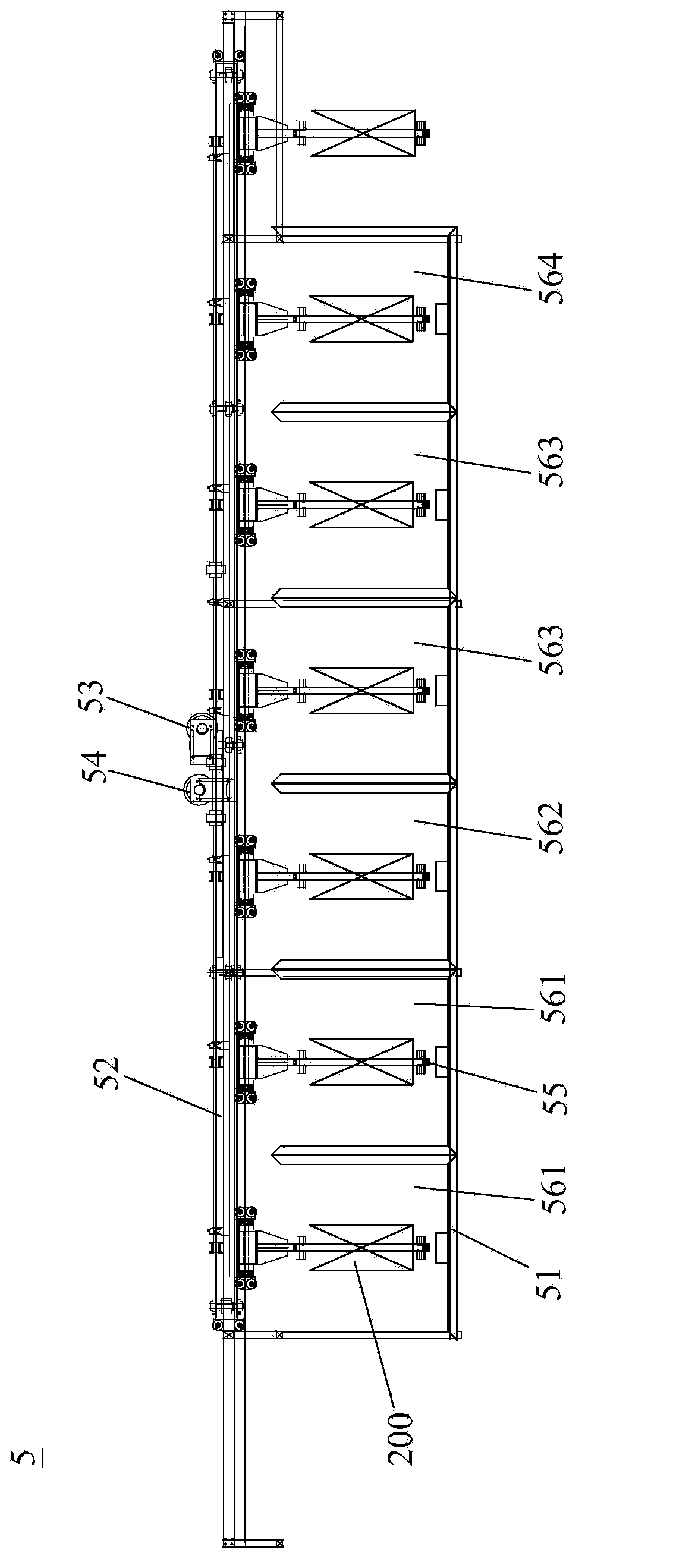

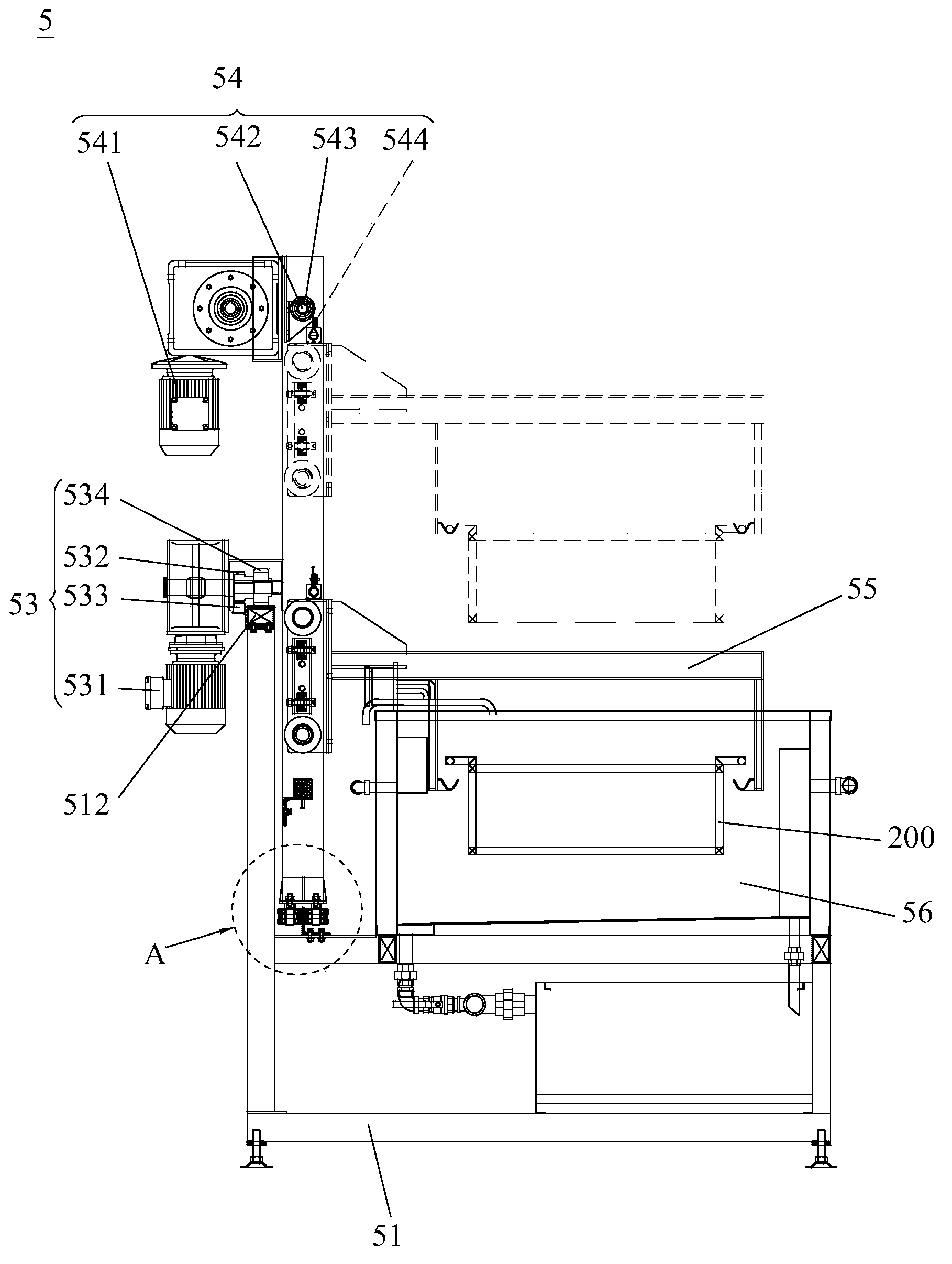

[0023] Such as figure 1As shown, the workpiece cleaning line 100 of the present invention cleans flat workpieces, and the workpieces are carried on the workpiece carrier 200. The workpiece cleaning line 100 includes a container 1, an upper part area 2, a stress relief furnace 3, a first Turning conveying device 4, cleaning device 5, drying furnace 6, second turning conveying device 7, conveyor belt 8, third turning conveying device 9, lower part area 10, grabbing device 101, fourth turning conveying device 102, the first Five steering conveying device 103 and control system (not shown in the figure); the upper area 2 is connected to one end of the stress relief furnace 3 through the first steering conveying device 4; the input end of the second steering conveying device 7 It is connected with the other end of the stress relief furnace 3, and the output end of the second diverting conveying device 7 is connected with one end of the cleaning device 5; the other end of the cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com