Method for extracting flavone substance from persimmon leaf by double water-phase extraction

A technology of persimmon leaf flavonoids and two-phase water, which is applied in the direction of solid solvent extraction, etc., can solve the problems of low extraction rate and cumbersome operation, and achieve the effect of simple method, quick effect and easy mastering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

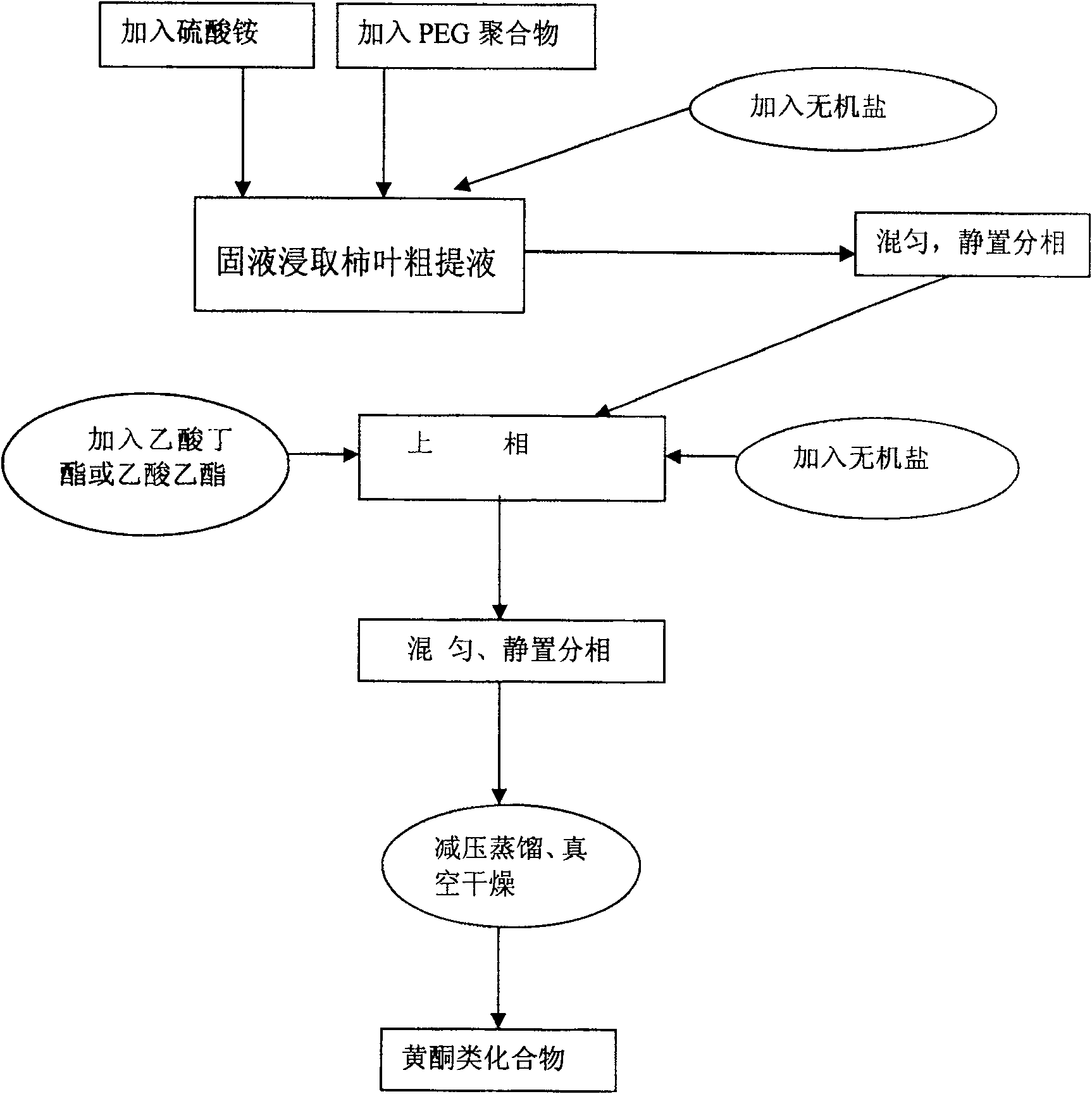

Image

Examples

Embodiment 1

[0033] (1) Solid-liquid leaching

[0034] Weigh 20 g of persimmon leaves that have been washed, removed, dried, and crushed, add 300 mL of 50% ethanol for reflux extraction for 3 hours, recover the solvent by distillation, filter the remaining extract to remove impurities, and obtain 153 g of filtrate.

[0035] (2) Aqueous two-phase extraction

[0036] Get above-mentioned filtrate, add 20g polyethylene glycol, 35g (NH 4 ) 2 SO 4 , 100g of water, and then add 5g of inorganic salt NaCl, mix well, and separate phases at 15°C for 2h to 6h.

[0037] (3) Butyl acetate or ethyl acetate stripping

[0038] Take out 124mL of the upper phase rich in polyethylene glycol polymer, add 50mL of water, 80mL of butyl acetate or ethyl acetate and 3g of NaCl, mix thoroughly, and let the system stand at room temperature for 1h-3h to separate phases completely into upper and lower phases. A two-phase, butyl acetate phase containing high amounts of flavonoids is for further processing.

[0039...

Embodiment 2

[0042] (1) Solid-liquid leaching

[0043] Weigh 20 g of persimmon leaves that have been cleaned, dried, and crushed, add 400 mL of 70% ethanol for reflux extraction for 5 h, recover the solvent by distillation, filter the remaining extract to remove impurities, and obtain 190 g of filtrate.

[0044] (2) Aqueous two-phase extraction

[0045] Get above-mentioned filtrate, add 25g polyethylene glycol, 45g (NH 4 ) 2 SO 4 , 95g of water, and then add 2g of NaCl, mix well, and separate the phases at 25°C for 2h to 6h.

[0046] (3) Butyl acetate or ethyl acetate stripping

[0047] Take out 186mL of the upper phase rich in polyethylene glycol polymer, add 75mL of water, 113mL of butyl acetate, 3g of NaCl, mix well, and let the system stand at room temperature for phase separation for 1h to 3h until it is completely divided into upper and lower phases. The butyl acetate phase, which contains high amounts of flavonoids, is for further processing.

[0048] (4) vacuum distillation, ...

Embodiment 3

[0051] (1) Solid-liquid leaching

[0052] Weigh 20 g of persimmon leaves that have been cleaned, dried, and crushed, add 500 mL of 60% ethanol for reflux extraction for 8 hours, recover the solvent by distillation, filter the remaining extract to remove impurities, and obtain 389 g of filtrate.

[0053] (2) Aqueous two-phase extraction

[0054] Get above-mentioned filtrate, add 35g polyethylene glycol, 65g (NH 4 ) 2 SO 4 , 125g of water, and then add 3g of inorganic salt NaCl, mix well, and separate phases at 30°C for 2h to 6h.

[0055] (3) Butyl acetate or ethyl acetate stripping

[0056] Take out 221mL of the upper phase rich in polyethylene glycol polymer, add 85mL of water, 126mL of butyl acetate, 3g of NaCl, mix thoroughly, and let the system stand at room temperature for phase separation for 1h~3h until it is completely divided into upper and lower phases. The butyl acetate phase, which contains high amounts of flavonoids, is for further processing.

[0057] (4) va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com