Integrated device for sewage pre-treatment in small mountainous town

A technology for sewage pretreatment and small towns, which is applied in the fields of dust and sand, sewage pretreatment grids, slag removal and sand removal devices. The effect of convenient slag and sand removal, small footprint and fast settlement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment figure, the present invention is described further in detail:

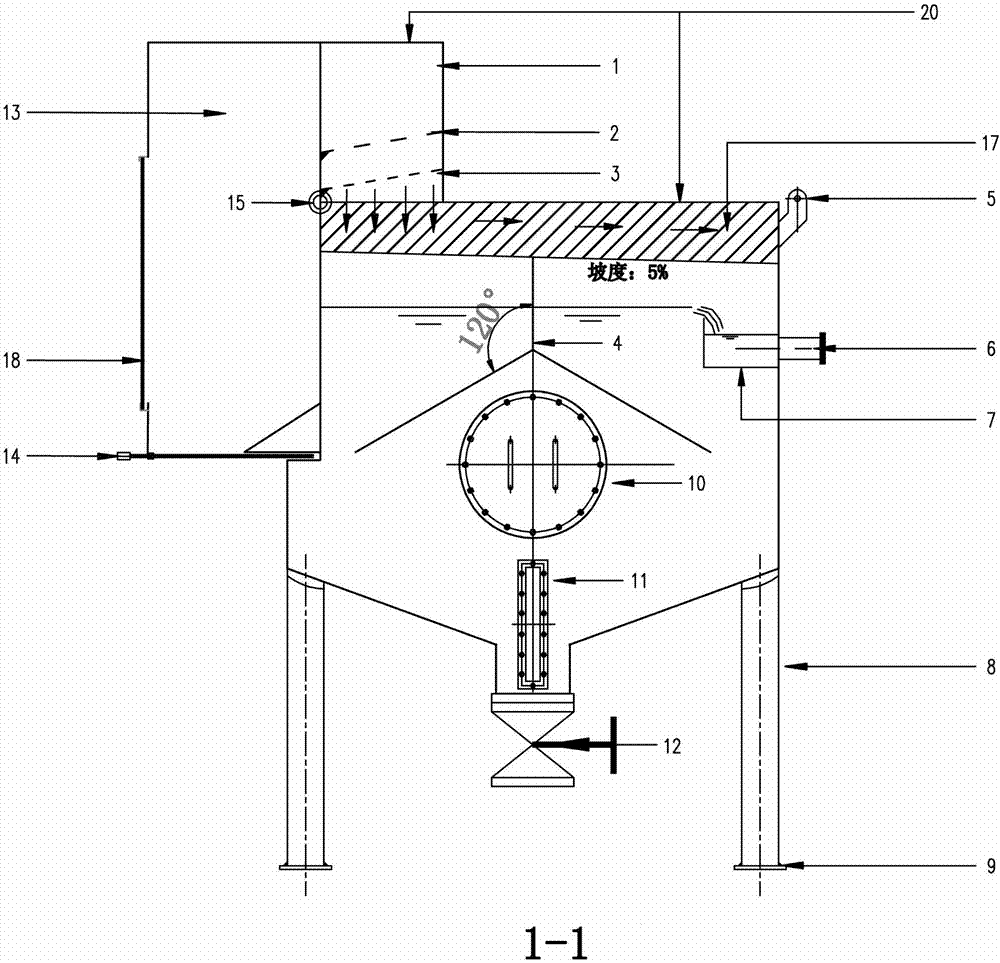

[0020] see figure 1 with figure 2 , the device includes a grille unit, a slag removal unit, a sand settling unit and a sand removal unit.

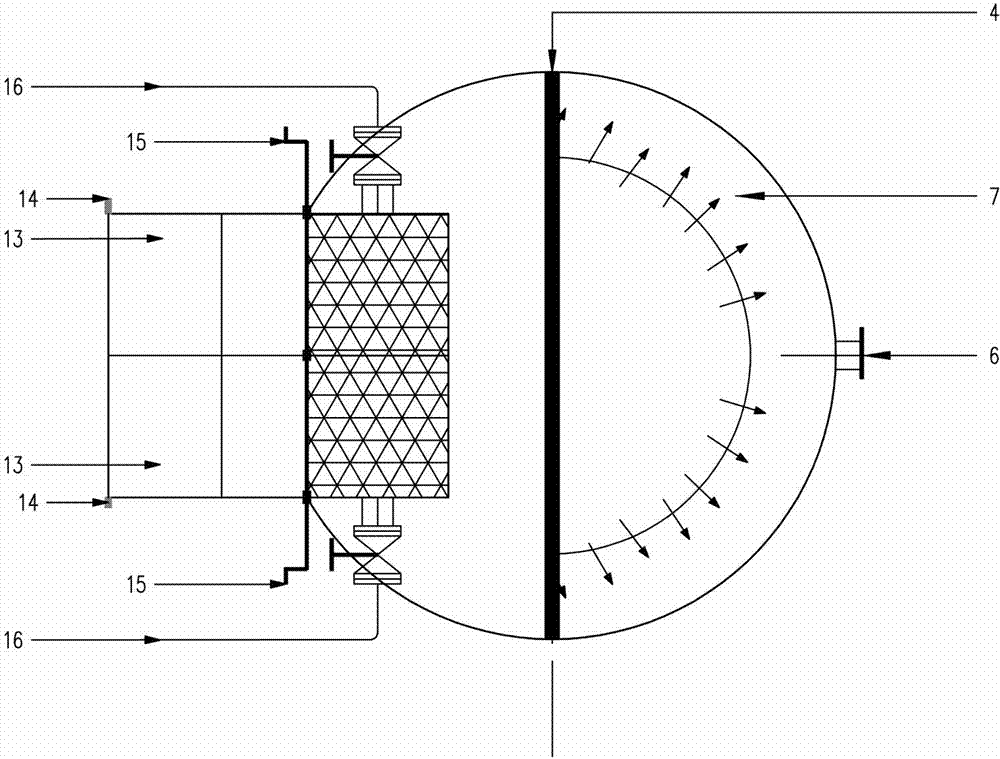

[0021] The grill unit is arranged on the top of the device, including a grill groove 1, a coarse grill 2 and a fine grill 3. The coarse grid 2 and the fine grid 3 are divided into upper and lower layers, installed in the grid tank 1, the upper part of the grid tank 1 is connected to the water pipe, and the bottom of the grid tank 1 is connected to the sand settling unit; the fine grid is welded together On the plate, the lower end of the plate is connected with the rotating shaft 15, see Figure 5 , When shaking and rotating, the thick and thin grille and plate can be turned over 180°.

[0022] see image 3 , The sand settling unit has a cylinder, a partition 4, a water outlet 6, a water outlet 7, a manhole 10, a sight glass 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com