Flame-retardant protective plastic plate

A technology of plastic board and flame retardant layer, which is applied in the field of plastic products, can solve the problems of no furniture board, no flame retardancy, high manufacturing cost, etc., and achieve good high temperature resistance and heat insulation effect, outstanding mechanical strength and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

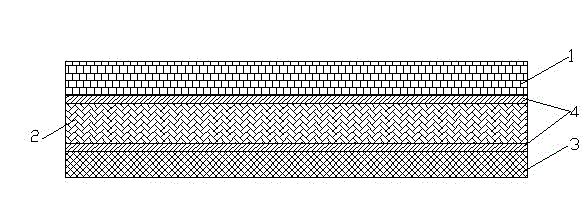

[0014] The present invention is a flame-retardant protective plastic board, see figure 1 , including the upper flame retardant layer 1, the middle layer high temperature resistant layer 2 and the lower layer heat insulation layer 3, the flame retardant layer 1 and the high temperature resistant layer 2, the high temperature resistant layer 2 and the heat insulation layer 3 are passed through The high temperature adhesive 4 is connected together, the flame retardant layer 1 is a polyphenylene ether plastic layer, the high temperature resistant layer 2 is a polysulfone plastic layer, the heat insulation layer 3 is a polypropylene plastic layer, and the high temperature resistant adhesive 4 It is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com