Wind-power steamship

A ship and wind technology, applied in the field of transport ships, can solve the problems of rapid wear, waste of energy resources, corrosion and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Further description will be made below in conjunction with description of drawings and specific embodiments

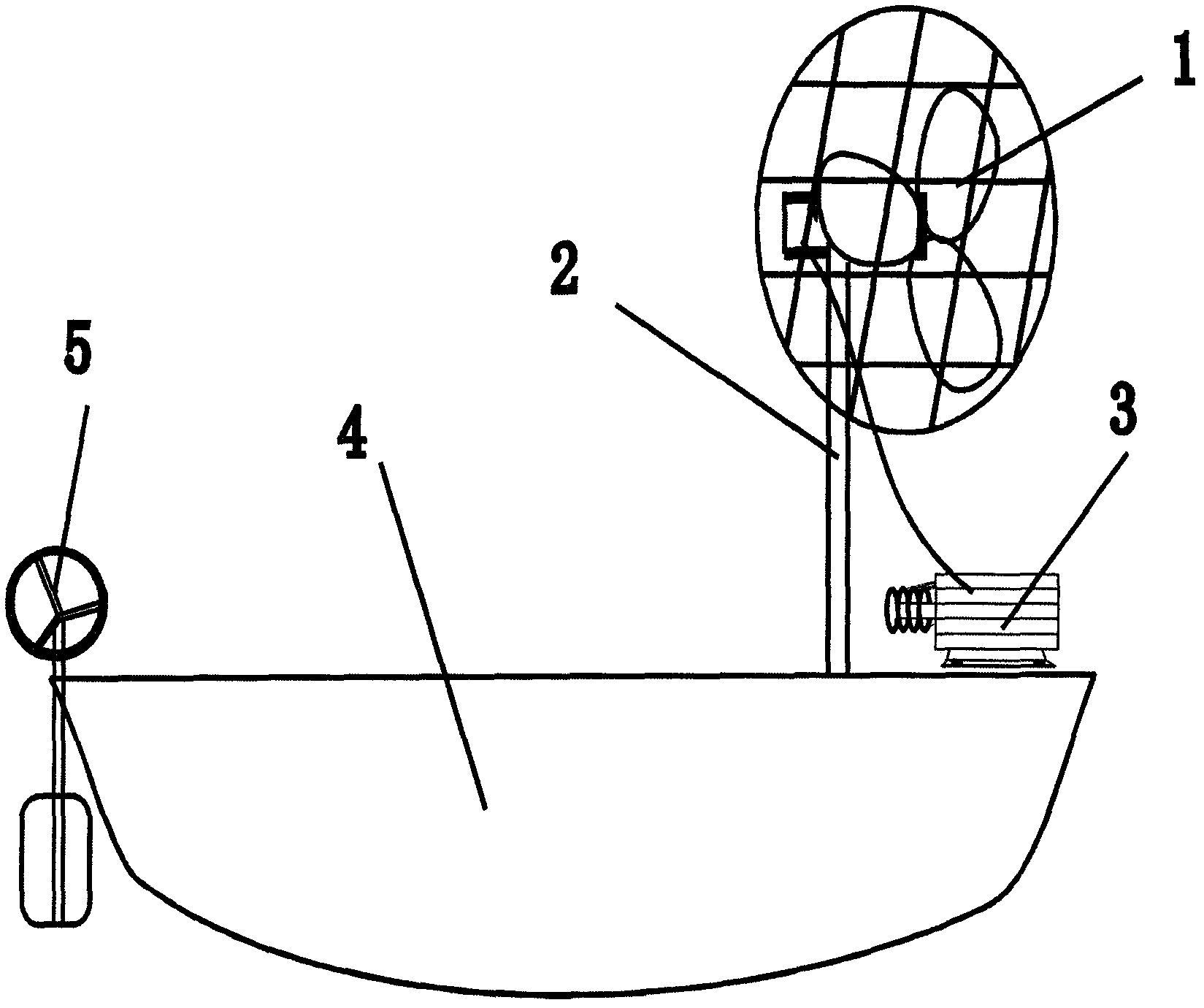

[0007] Depend on figure 1 It can be seen that a wind-powered ship is composed of a rotating impeller 1, a bracket 2, a power generator 3, a hull 4 and a helmsman 5, the rotating impeller 1 is installed above the bow bracket 2, and the rotating impeller 1 relies on the power provided by the power generator 3 to rotate , and can rotate clockwise or counterclockwise, the helmsman 5 is at the stern of the hull 4, the electric motor above the generator 3 power supply bracket rotates, and the electric motor drives the rotating impeller 1 to rotate, and the reaction force of the air is used to make the ship move forward. When the ship needs to move forward , the rotating impeller rotates clockwise, blowing backwards, relying on the reaction force of the air, the ship will move forward, on the contrary, the rotating impeller will rotate counterclockwise, and the ship wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com