Precision comparison and precision compensation method for ultra-precision manufacturing equipment based on bond length of graphene

A graphene and ultra-precision technology, which is applied in the field of sub-nanometer precision comparison and precision compensation of ultra-precision manufacturing equipment, can solve problems such as poor measurement stability, achieve good stability, and avoid secondary clamping errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings. This method is implemented on the TECNAI20U-TWIN high-resolution transmission electron microscope of the Netherlands Philips (PHILIPS) company. The pattern generator used is DY2000A.

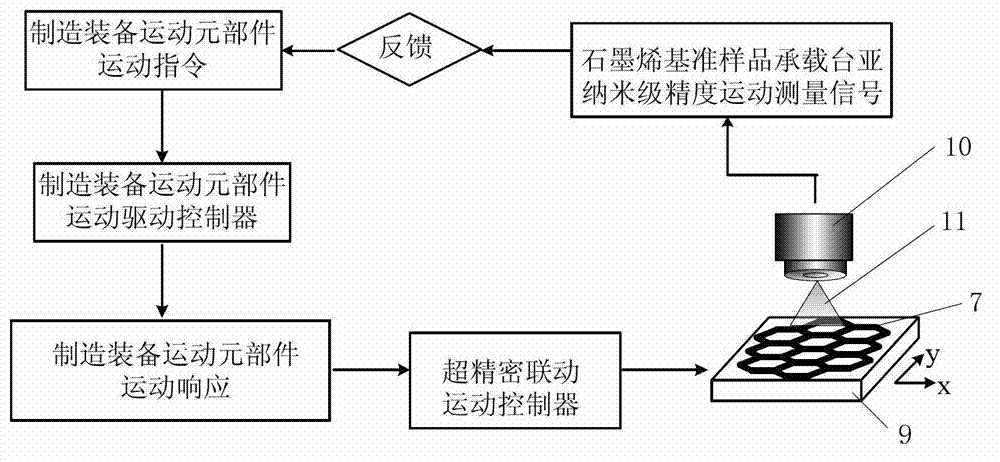

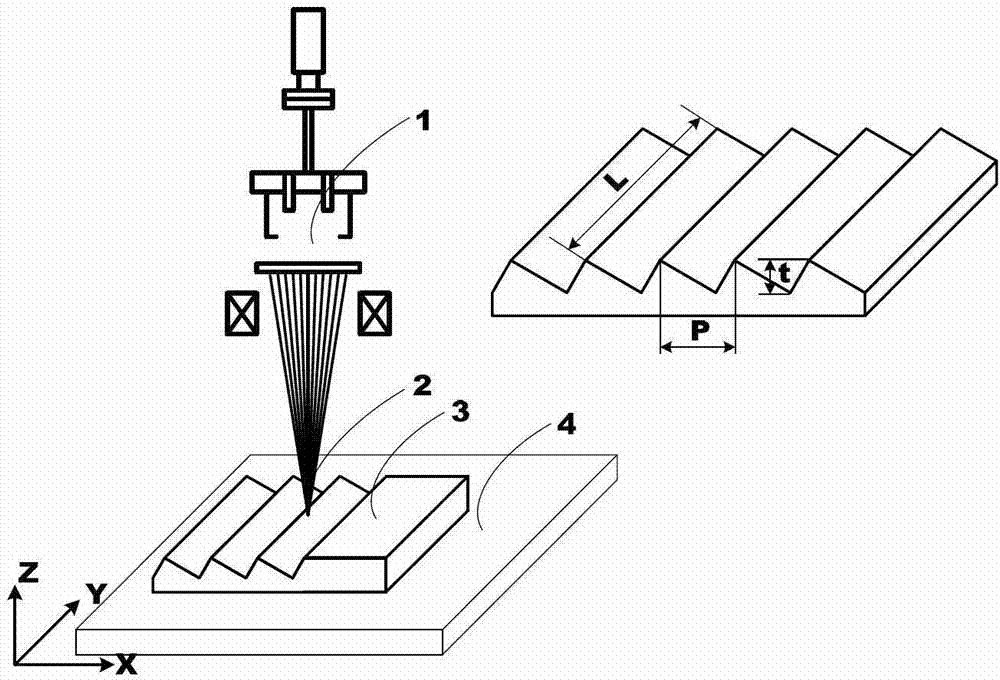

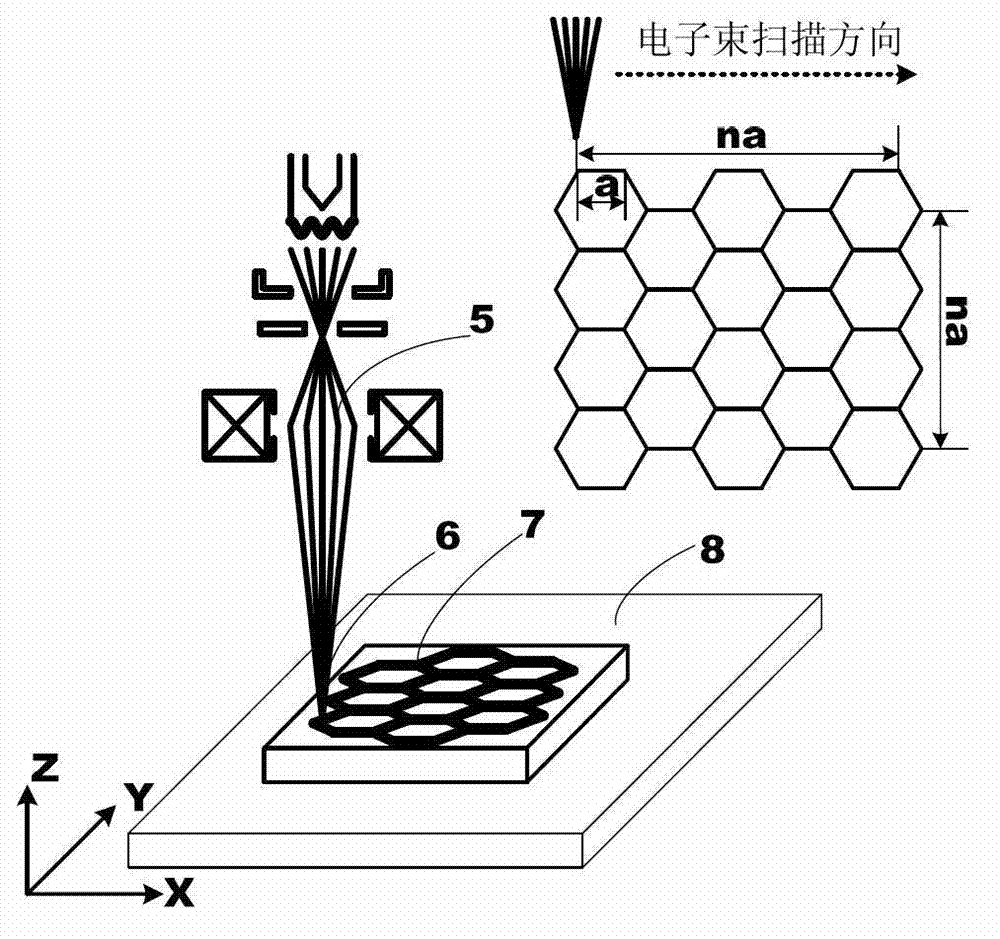

[0018] figure 1 It is a motion control and detection block diagram of the method of the present invention. figure 2 It is a schematic diagram of an ultra-precision machining device according to the method of the present invention (in this example, high-energy beam processing is taken as an example), wherein 1 is a high-energy beam emitting device, 2 is a high-energy beam spot, 3 is a workpiece, and 4 is a manufacturing equipment moving element Components (in this example, a moving platform); the processed feature structure includes groove depth t, period P, and groove length L. image 3 It is a schematic diagram of the detection device of the method of the present invention (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com