Precision Electric Grinding Technology of Tiny Ball Seat Surface of High Pressure Common Rail Diesel Engine Injector

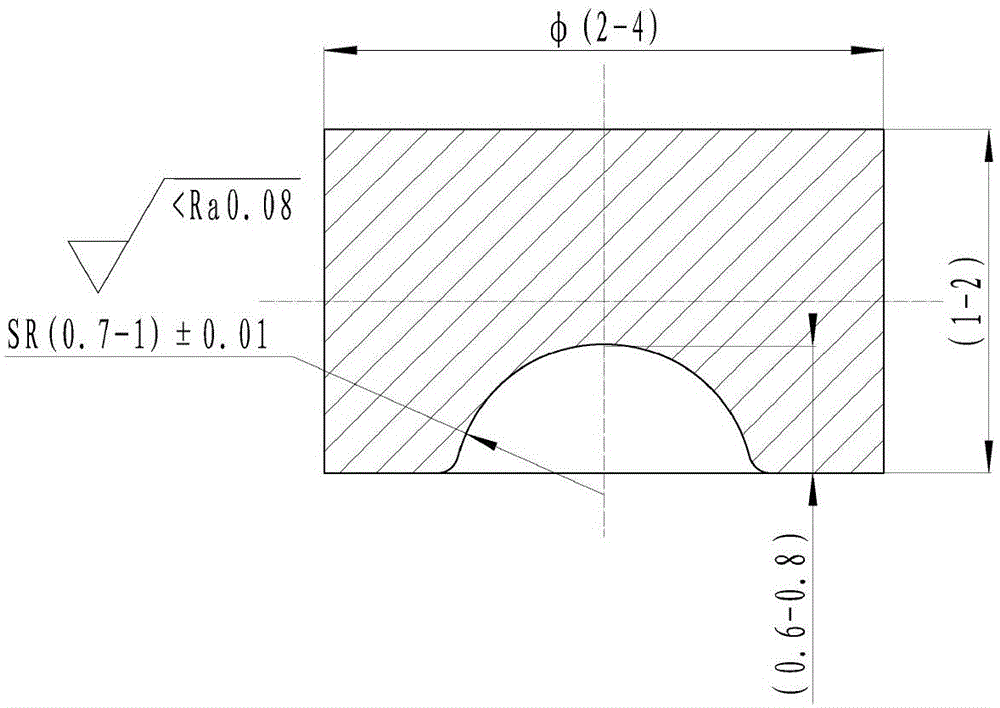

A diesel engine and high-pressure common rail technology, which is applied in the precision machining of the concave micro-sphere crown surface and the precision electric grinding process of the micro-ball seat surface of the high-pressure common-rail diesel engine injector, can solve the problem that the shape of the micro-ball seat surface cannot be achieved Dimensional accuracy requirements, the inability to meet the surface processing accuracy requirements of the micro-ball seat surface, and the inability to form three-dimensional micro-miniature cavities with high dimensional accuracy, etc., to achieve the effects of easy discharge of processed products, avoiding processing errors and surface burns, and improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention belongs to the technical field of micro-special processing, and in particular relates to a precision electric grinding process for the micro-ball seat surface of a high-pressure common rail diesel engine injector. The process flow, process steps and process of the present invention will be described below in conjunction with the accompanying drawings and implementation examples condition.

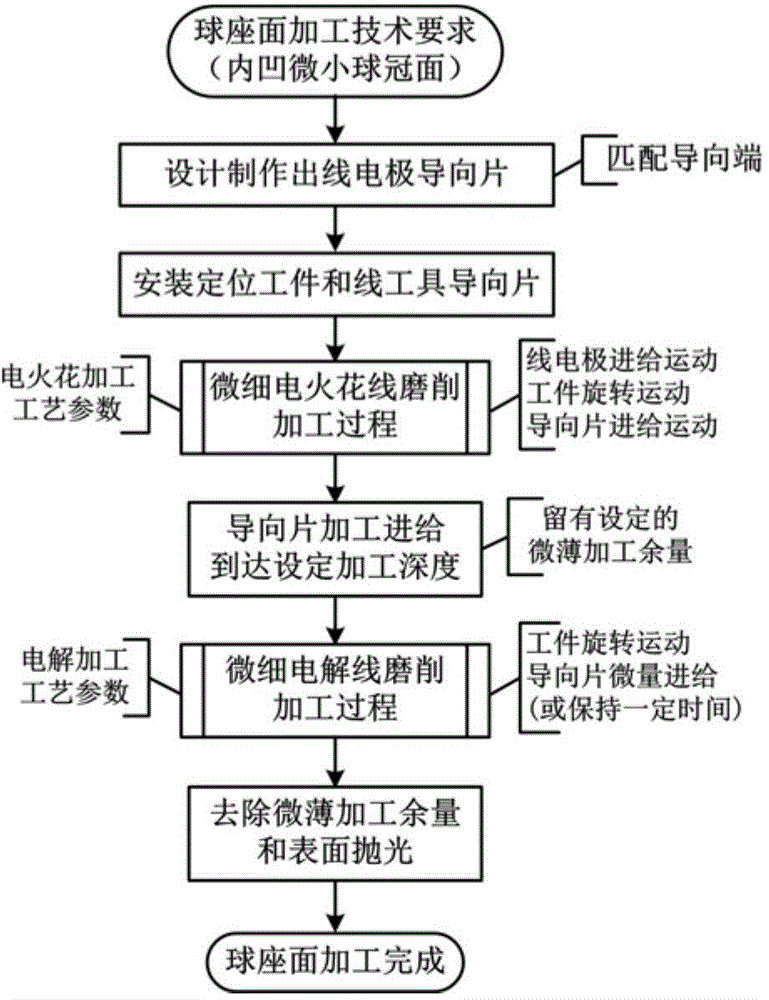

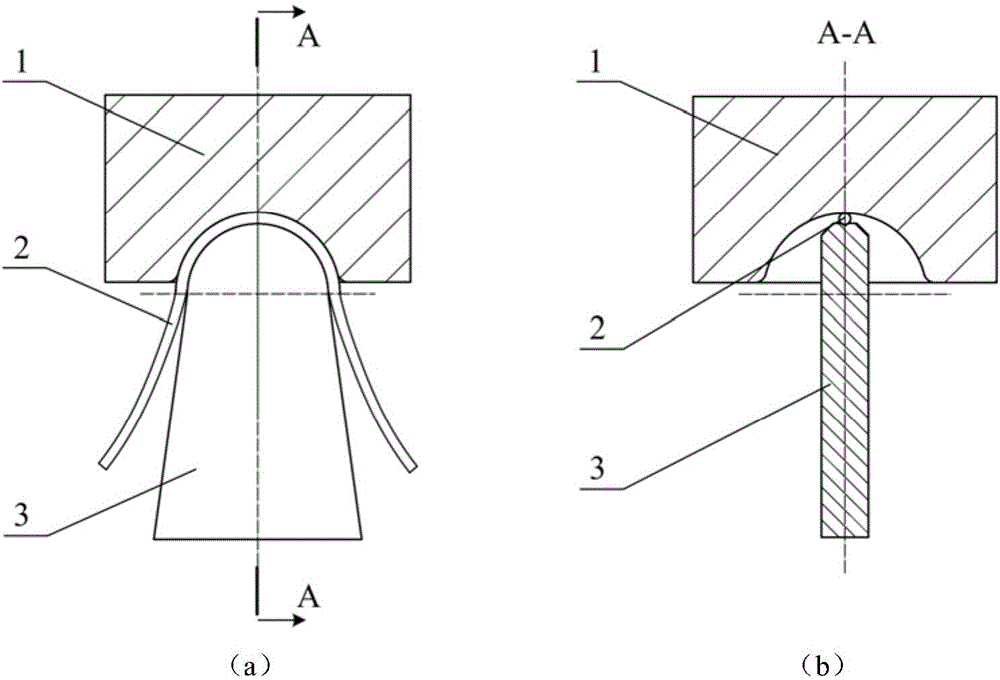

[0038] like figure 1 As shown, the precision micro electric grinding process of the micro-ball seat surface (concave micro-sphere crown surface) of the high-pressure common rail diesel engine injector mainly includes the following steps: According to the size of the ball seat surface (concave micro-sphere crown surface), Design and manufacture matching wire electrode guide pieces with arc-shaped guide ends; install and position the workpiece on the ball seat surface and the wire electrode guide piece to ensure the coaxial accuracy of the symmetry axis of the gui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com