Insulator glaze capable of identifying phases of power line and product of same

A technology for insulators and power lines, applied in the field of identifying power line phase insulator glazes and its products, can solve problems such as inconspicuousness, confusion, and impermanence, and achieve the effects of clearly distinguishing phases, facilitating construction, and convenient laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

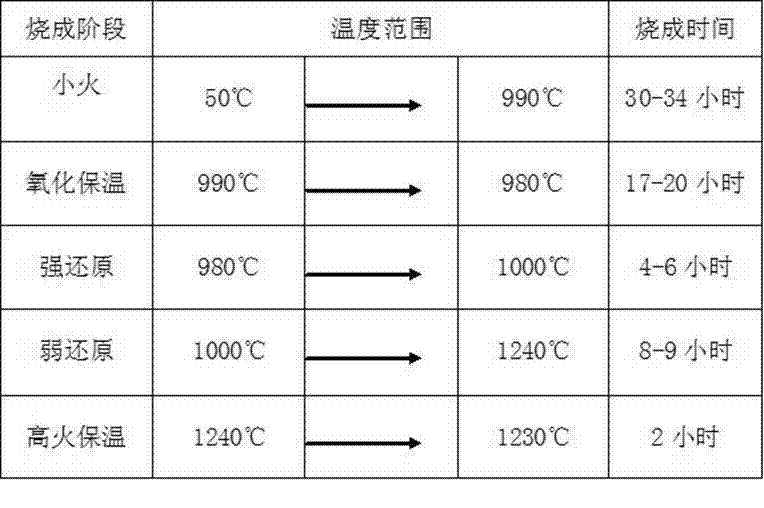

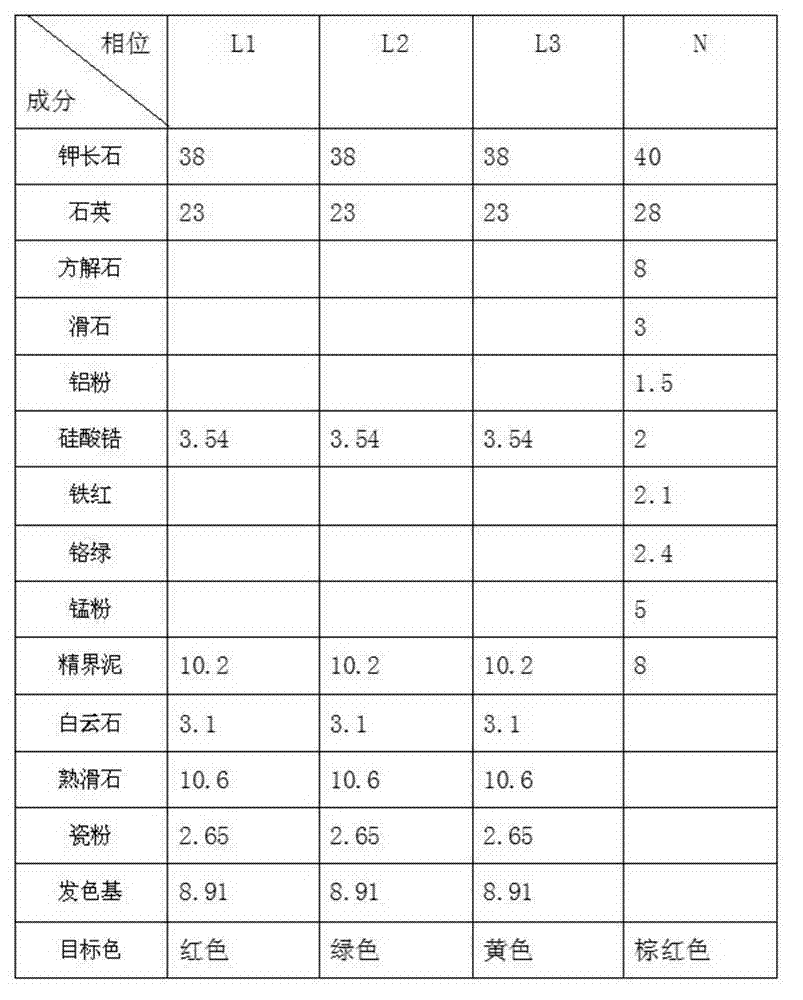

[0030] Example 1: Color the prepared four-color glaze on the body of the porcelain insulator correspondingly, where red corresponds to L1 phase, green corresponds to L2 phase, yellow corresponds to L3 phase, and brown-red corresponds to N phase. For firing, it takes 30 hours to heat from 50°C to 990°C in the low fire stage; maintain the temperature between 990°C and 980°C for 18 hours in the oxidation and heat preservation stage; control the temperature between 980°C and 1000°C for 5 hours in the strong reduction stage; After 8 hours in the weak reduction stage, the temperature is heated from 1000°C to 1240°C; in the high-fire heat preservation stage, the temperature is maintained between 1240°C and 1230°C for 2 hours.

Embodiment 2

[0031] Embodiment 2: Color the prepared four-color glaze correspondingly on the embryo body of the porcelain insulator, wherein brown-red corresponds to L1 phase, green corresponds to L2 phase, yellow corresponds to L3 phase, and red corresponds to N phase. For firing, it takes 34 hours to heat from 50°C to 990°C in the low fire stage; maintain the temperature between 990°C and 980°C for 20 hours in the oxidation and heat preservation stage; control the temperature between 980°C and 1000°C for 4 hours in the strong reduction stage; After 8.5 hours in the weak reduction stage, the temperature is heated from 1000°C to 1240°C; in the high-fire heat preservation stage, the temperature is maintained between 1240°C and 1230°C for 2 hours.

Embodiment 3

[0032] Embodiment 3: Color the prepared four-color glaze correspondingly to the embryo body of the porcelain insulator, where red corresponds to L1 phase, yellow corresponds to L2 phase, green corresponds to L3 phase, and brown-red corresponds to N phase. For firing, it takes 32 hours to heat from 50°C to 990°C in the low-fire stage; maintain the temperature between 990°C and 980°C for 17 hours in the oxidation and heat preservation stage; control the temperature between 980°C and 1000°C for 6 hours in the strong reduction stage; After 9 hours in the weak reduction stage, the temperature is heated from 1000°C to 1240°C; in the high-fire heat preservation stage, the temperature is maintained between 1240°C and 1230°C for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com