Safety control method for blast furnace minter process slag treatment granulation water supply system

A technology of granulated water supply and system safety, which is applied in the field of safety control of blast furnace slag treatment granulated water supply system, can solve problems such as increasing system operating costs, unbalanced pump unit load rate, affecting system stability and life, etc., to achieve Strong early warning and accident handling capabilities, reasonable intelligent control, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

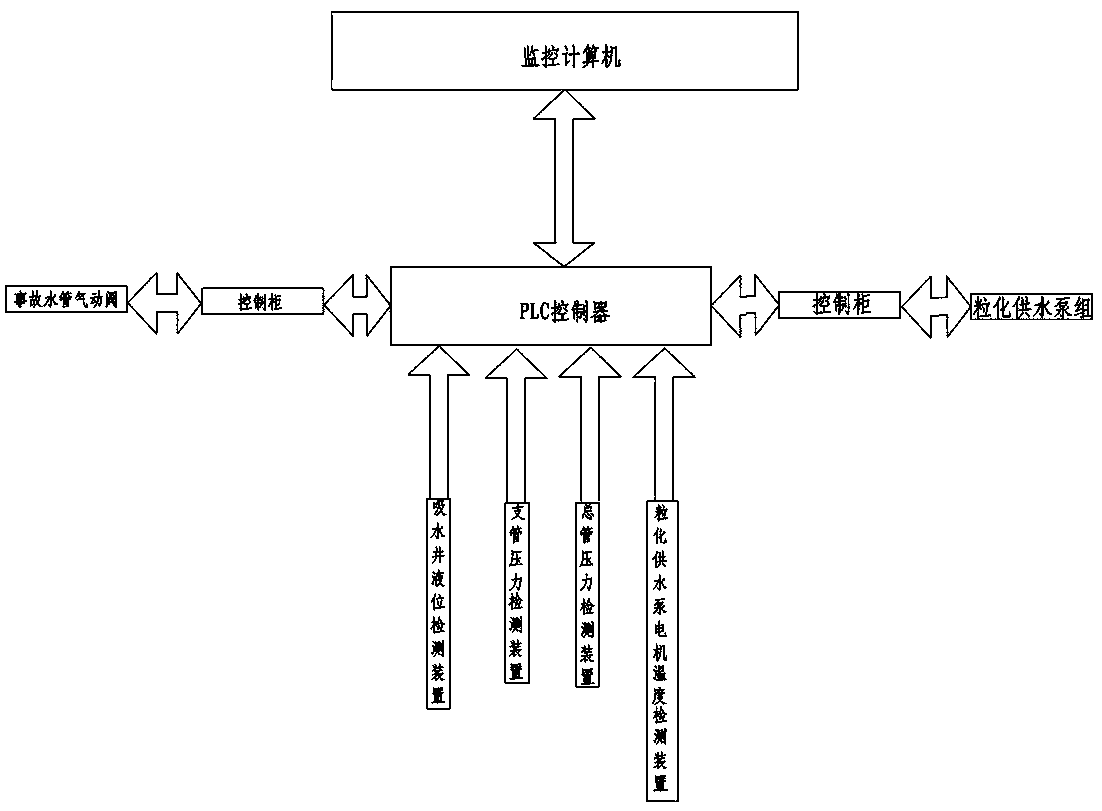

[0038] figure 2 It is a schematic block diagram of the hardware structure of an embodiment of the present invention, which includes a signal acquisition device, a controller for processing the data collected by the signal acquisition device (in this embodiment, a PLC controller, that is, a programmable logic controller), The executive mechanism used to control the switch of the pneumatic valve of the emergency water pipe and / or the switch of the internal pump motor of the granulation water supply pump, the monitoring device (in this embodiment, a monitoring computer) used to issue control instructions according to the data processed by the controller, and the signal acquisition device It is connected with the input end of the controller, the output end of the controller is connected with the actuator, and the control end of the controller is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com