Water quenching thermal treatment adjustable device of steel cord brass electroplating operation line

A technology for working lines and steel cords, used in quenching devices, heat treatment furnaces, heat treatment equipment, etc., can solve the problems of large power consumption, economic losses of enterprises, burns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

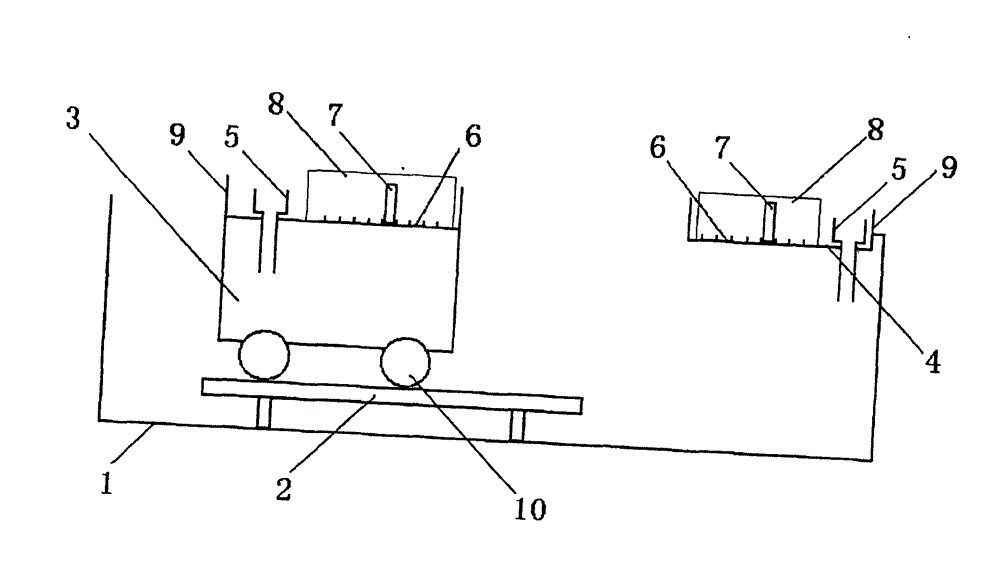

[0007] As shown in the figure, an adjustable device for water quenching heat treatment of a steel cord electroplating brass operation line, the lower end of the water bath 1 is provided with a guide rail 2, and the bottom of the mobile working tank 3 is provided with a roller 10, and the roller 10 is located on the guide rail 2. The mobile working tank 3 and the fixed working tank 4 are respectively equipped with a liquid lifting device 5, an end plate 9 and an adjusting tank 6, and a moving plate 7 is inserted in the adjusting tank 6 on the moving working tank 3 in parallel with the end plate 9, and the moving work The adjustment groove 6 on the groove 3 is also provided with a water barrier 8 perpendicular to the end plate 9 and the moving plate 7, and the moving plate 8 is inserted in the adjusting groove 6 on the fixed working groove 4 parallel to the end plate 9, and the fixed working groove 4. In the adjustment groove 6, there is also a water barrier 8 perpendicular to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com