Automatic braking force regulating device for screw oil pump

An automatic adjustment and oil well pump technology, which is applied in pump control, pump components, machines/engines, etc., can solve the problems of poor safety and accidents of oil well operators, and achieve the effect of reducing the degree of danger, improving efficiency, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

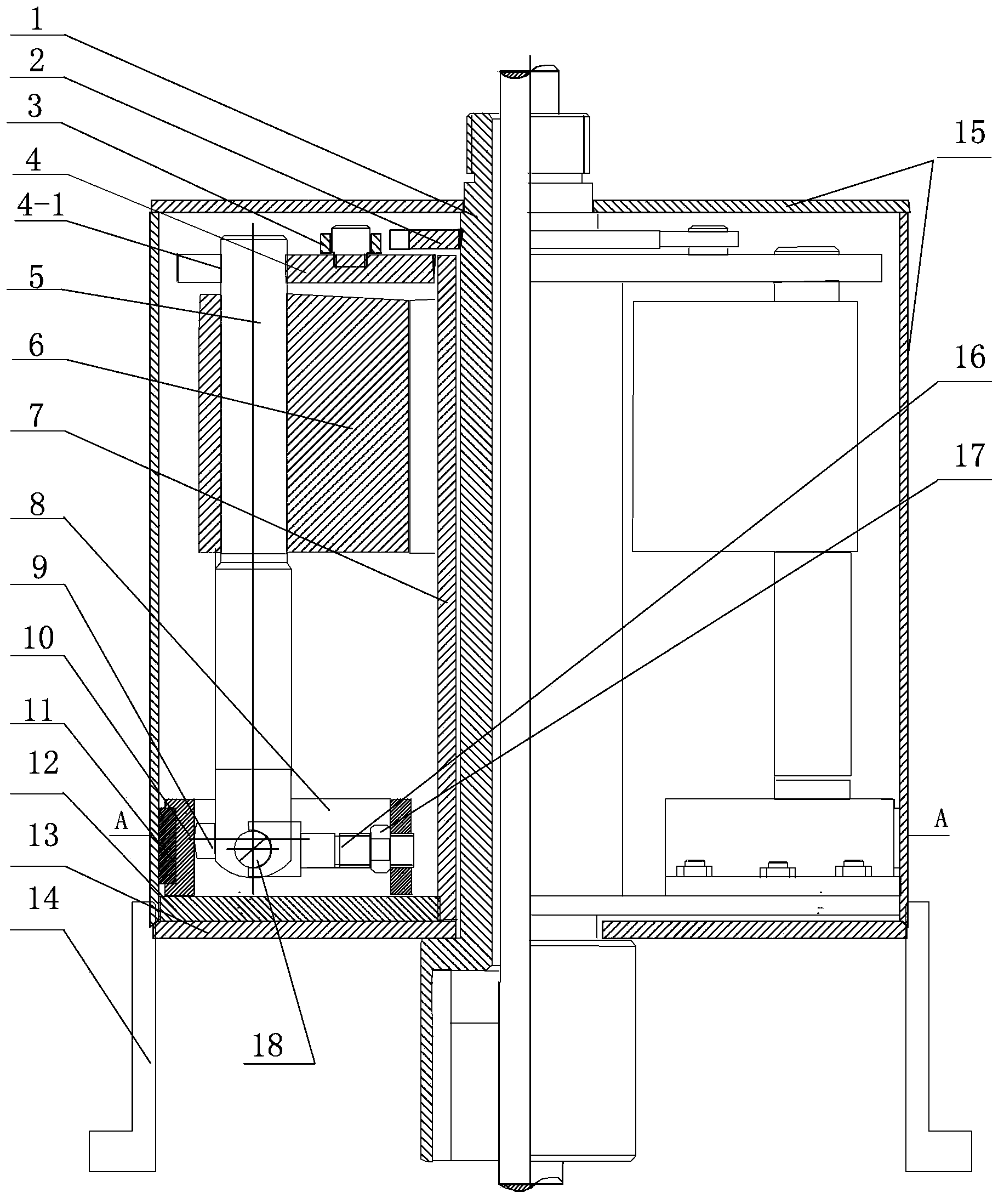

[0007] Specific implementation mode 1: Combination figure 1 To explain this embodiment, the device of this embodiment includes a branch pipe 1, a ratchet tooth 2, a pawl 3, a brake disc 4, a brake disc connecting pipe 7, a brake chassis 12, a base 13, a housing 15, and a rotating pin 18. , Two levers 5, two counterweights 6, two multifunctional brackets 8, two special-shaped cams 9, two friction plate fixing frames 10 and two friction plates 11, the bottom of the housing 15 is fixedly connected to the base 13 , Ratchet teeth 2, pawl 3, brake disc 4, brake disc connecting pipe 7, brake chassis 12, two levers 5, two counterweights 6, two multifunctional brackets 8, two special-shaped cams 9 , The two friction plate holders 10 and the two friction plates 11 are both installed in the housing 15. The upper end of the branch pipe 1 passes through the upper end surface of the housing 15 and is set on the outside of the housing 15 and the two are rotatably connected. The lower end pass...

specific Embodiment approach 2

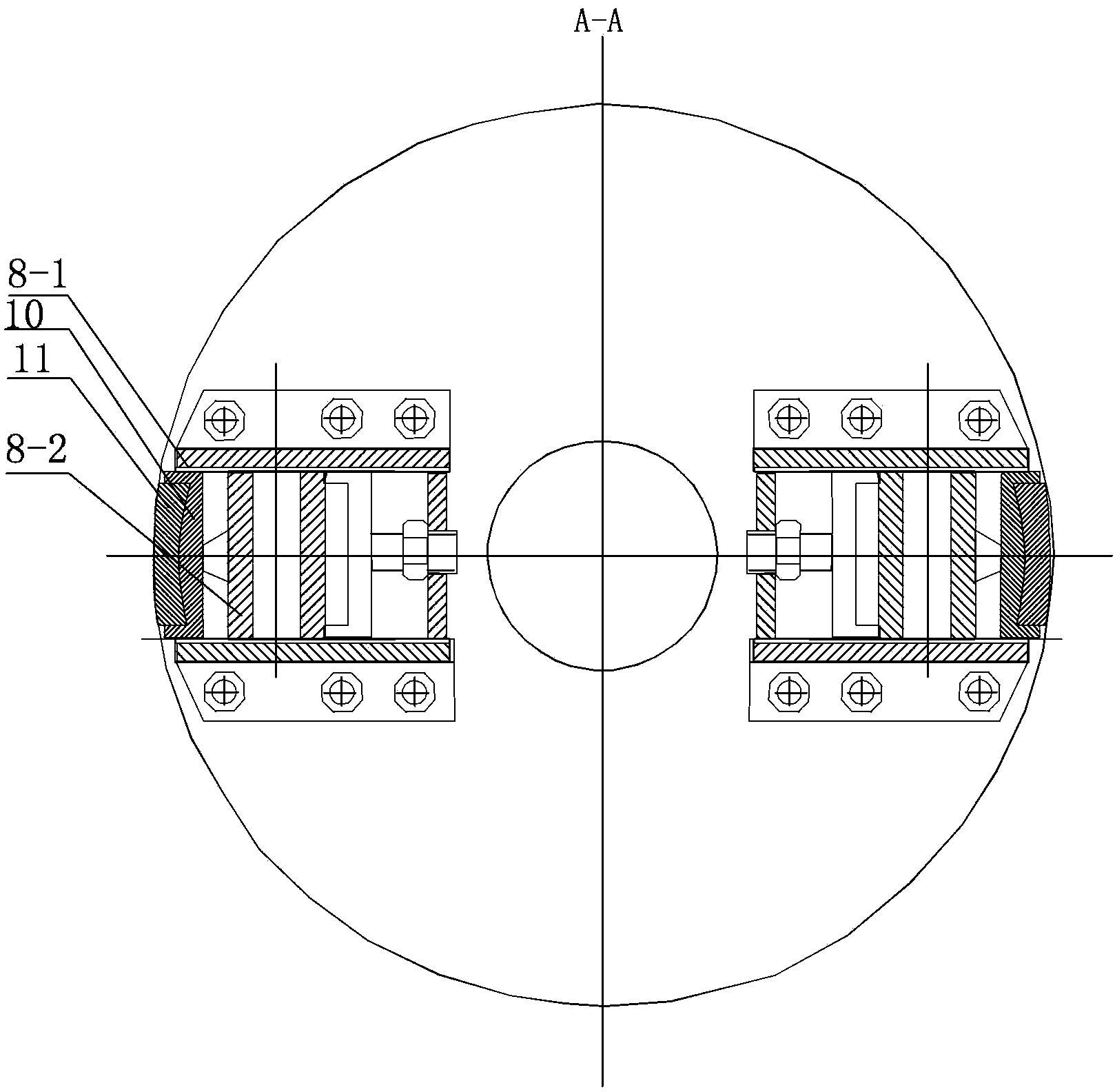

[0010] Specific implementation manner two: combination figure 2 To illustrate this embodiment, the multifunctional bracket 8 of this embodiment is composed of two rails 8-1 and a plurality of cross bars 8-2, the two rails 8-1 are arranged in parallel, and the plurality of cross bars 8-2 are arranged in parallel. Between the rails 8-1 and each crossbar 8-2 is arranged perpendicular to the rail 8-1, the friction plate 11 fixed on the friction plate fixing frame 10 can only run along the brake chassis 12 under the restriction of the multifunctional bracket 8. The relative movement in the radial direction can not be relative rotation. The other embodiments are the same as the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the brake disc 4 of this embodiment is provided with a groove 4-1, the upper end of the lever 5 is provided in the groove 4-1, and the groove 4-1 on the brake disc 4 restricts the upper end of the lever 5 to only Relatively move along the radial direction of the brake disc 4 and cannot rotate relatively. The other embodiments are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com