Small-caliber header conical internal pressure sealing device for boiler

A sealing device and small-diameter technology, which is applied to boiler drums/box headers, engine sealing, lighting and heating equipment, etc., can solve the problems of easy wear of the sealing surface, narrow sealing surface width, and difficulty in cleaning, etc., to achieve Keep the sealing effect, the life is not easy to damage, and the sealing effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

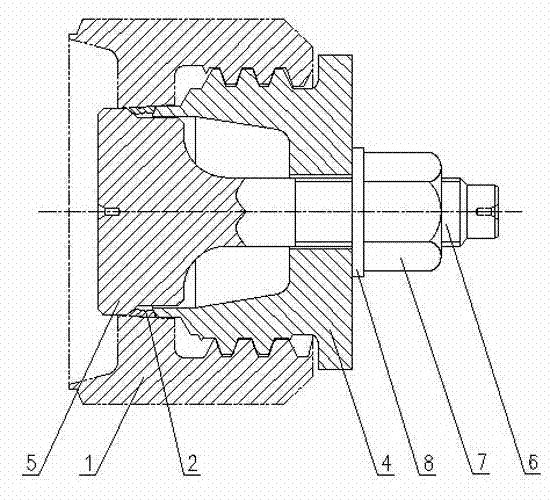

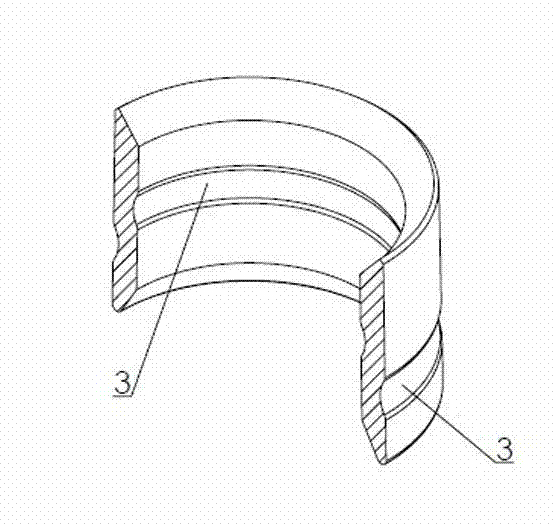

[0016] Examples of the present invention figure 1 As shown, the conical internal pressure sealing device of the small-bore header of the boiler is characterized in that the main body of the header 1 is provided with a circular hole, the inner surface of the circular hole is a conical surface, and the conical surface shrinks toward the inside of the header and opens to the outside. The taper of the surface is 1:15, corresponding to the concentric surface of the conical surface, a sealing metal sleeve 2 is provided concentrically, and the inner and outer surfaces of the sealing metal sleeve 2 are respectively provided with annular expansion grooves 3, and the depth of the expansion groove 3 is smaller than the wall of the sealing metal sleeve 2 One-third of the thickness, the inner chamfer of both ends of the sealing metal sleeve 2 is a bevel; the sealing metal sleeve 2 is connected with the pressure block 4 through the bevel at the large-diameter end of the conical surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com