Method for determining residual butt welding stress of aluminum alloy sheets

A technique of residual stress, determination method, applied in the direction of measuring force, measuring device, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below through a specific embodiment. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

[0017] The steps of the present invention are as follows:

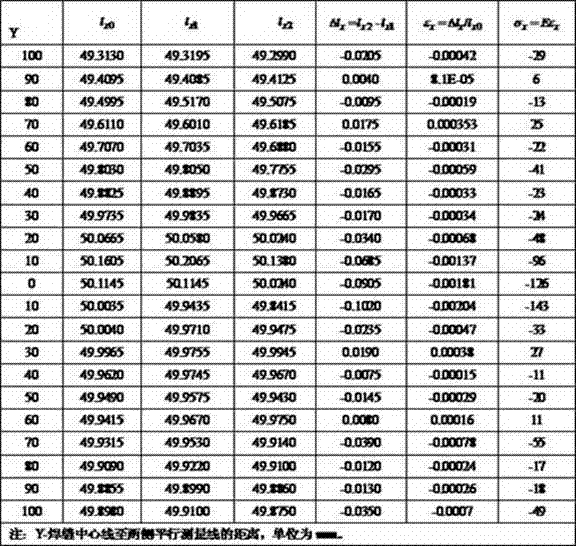

[0018] 1) Before welding the aluminum plate, use a marking tool to mark at least 2 marking lines with a line mark width not greater than 0.05mm in the welding heat-affected zone of the aluminum plate along the direction parallel to the weld, and set the middle distance on the same side of the weld The same two marking lines are a group, use the measuring tool to measure the distance between the two marking lines in each group;

[0019] 2) After the aluminum plate is welded, measure the distance between the two marking lines in each group again;

[0020] 3) Cut at least one cut strip along the vertical direction of the marked line, measure the distance b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com