Method and device for preparing tri-axial test samples including sandwich layers

A triaxial test and interlayer technology, applied in the preparation of test samples, etc., can solve problems such as difficult control of crack thickness, inclination and position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Contain the method for sample preparation of interlayer triaxial test sample, its steps are:

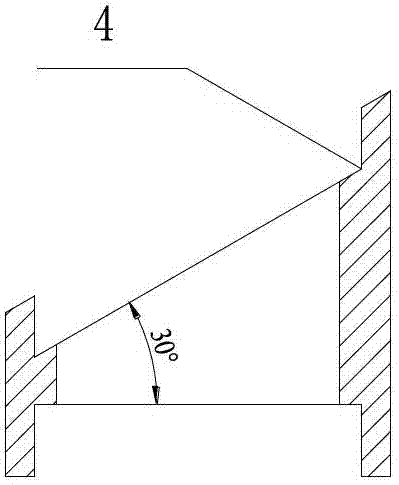

[0051] The following is to make the main material of the lower part of a sample: soil sample A, passed through a 2mm sieve, with a water content of 20% and a density of 1.8g / cm 3 Medium expansive soil, a kind of interlayer material: interlayer soil sample B, passed through a 2mm sieve, with a water content of 23%, and a density of 1.6g / cm 3 Strong expansive soil, a main material of the upper part of the sample: soil sample C, passed through a 2mm sieve, with a water content of 18% and a density of 1.7g / cm 3 The medium expansive soil, the interlayer is located in the center of the cylindrical sample, the thickness of the interlayer is 10mm, and the sample preparation method of the interlayer with an inclination angle of 30 degrees is taken as an example to illustrate the specific operation process of this device. See the attached manual for the sample effect Figure 9 .

[0...

Embodiment 2

[0064] The present invention will be described in further detail below according to accompanying drawing:

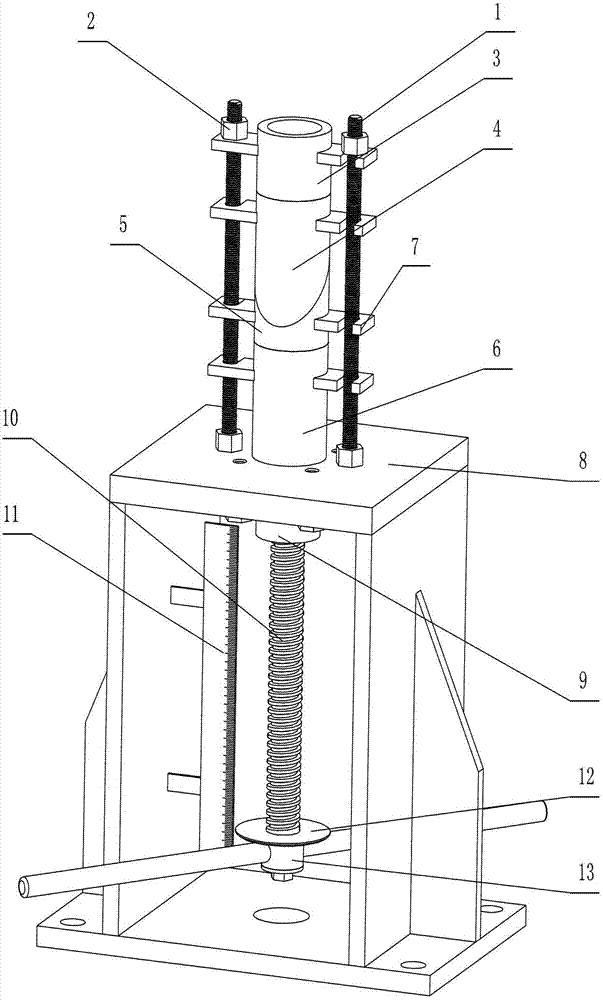

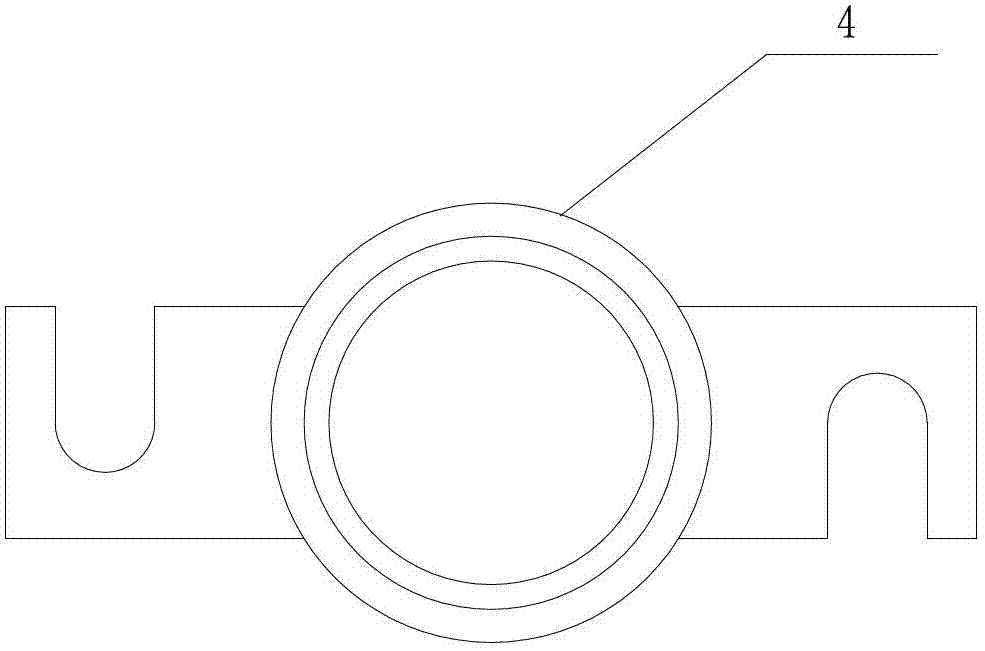

[0065] Triaxial test sample device with interlayer, which consists of sample preparation mold fixing screw 1, sample preparation mold fixing nut 2, upper general sample preparation mold 3, upper inclined section sample preparation mold 4, lower inclined section sample preparation mold 5, lower Universal sample preparation mold 6, mold fixing bracket 7, sample preparation base 8, sample push rod fixed base 9, trapezoidal tooth sample push screw 10, sample push rod positioning scale 11, sample push rod positioning mark 12, The sample pushing rod is driven by a wrench 13, a cushion block 14, a soil sample A15, an interlayer soil sample B16, and a soil sample C17.

[0066]It is characterized in that: the base 7 of the sample preparation device is a gate-shaped structure welded by steel plates, the top plate of the base of the sample preparation device is 16 mm thick, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com