Testing method of electrotinning uniform plating capacity

A technology of throwing ability and testing method, which is applied in the field of testing the throwing ability of additives, can solve the problems of large difference in current density, large difference in area, rough tin layer and no corrosion resistance, etc., to avoid deviation of results and simple test method , the effect of accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

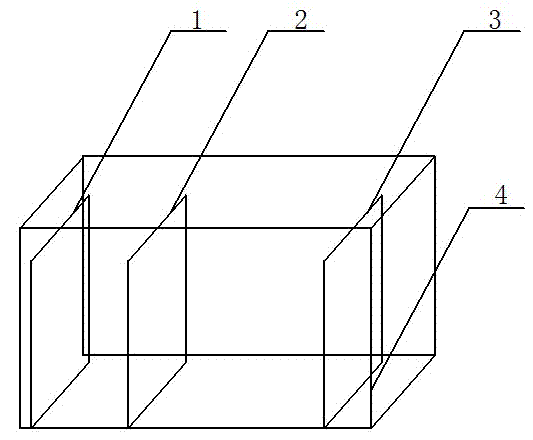

[0018] see figure 1 , the device diagram of the electroplating tin throwing ability test method, the near cathode 1 and the far cathode 3 in the electroplating tank body 4 are degreased and slightly etched, dried, and then weighed to obtain the weight m of the near cathode 1 1 and the weight of the far cathode 3 m 2 ; Connect the anode 2 to the positive pole of the rectifier, the near cathode 1 and the far cathode 3 to the rectifier negative pole; connect the current, start electroplating, after the electroplating is completed, dry the near cathode 1 and the far cathode 3, and then weigh to obtain the near cathode after electroplating 1 weight m 1 ′ and the weight m of the far cathode 3 after electroplating 2 ′; calculate the throwing power,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com