Microscope device for detecting printed circuit board (PCB)

A microscope and microscopic imaging technology, which is applied in the direction of microscope, optical test defect/defect, optics, etc., to improve the detection effect and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

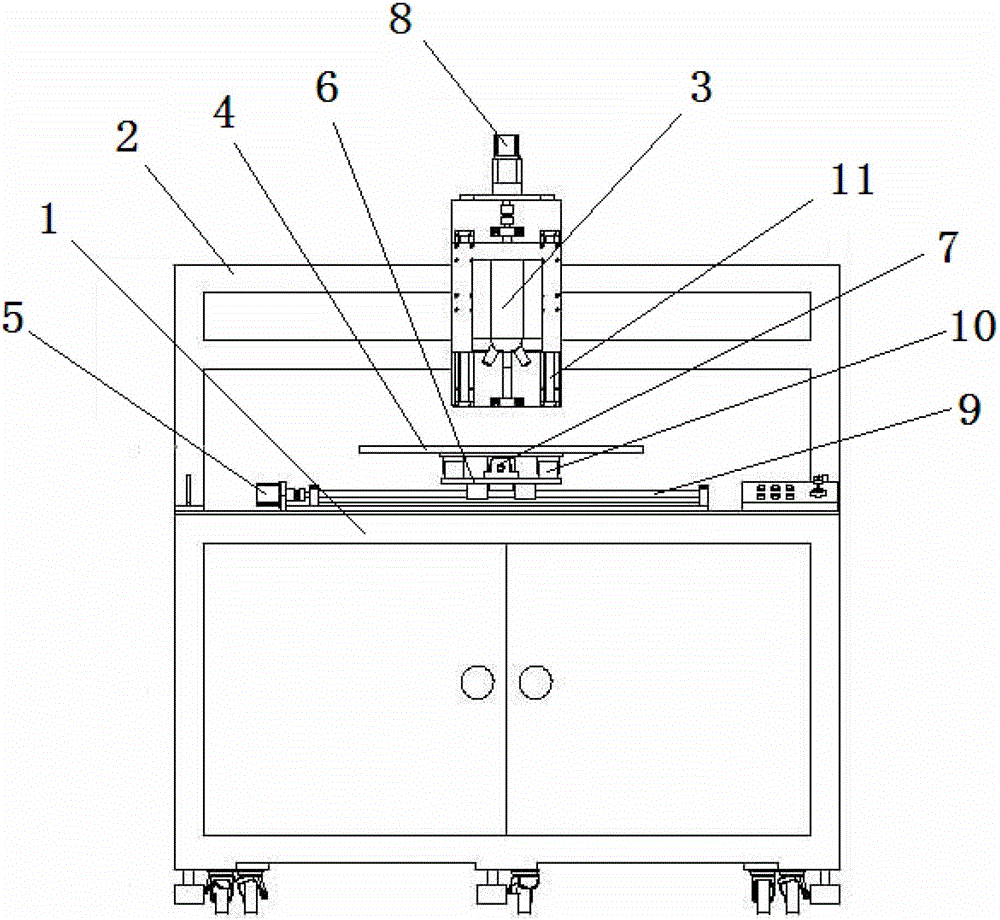

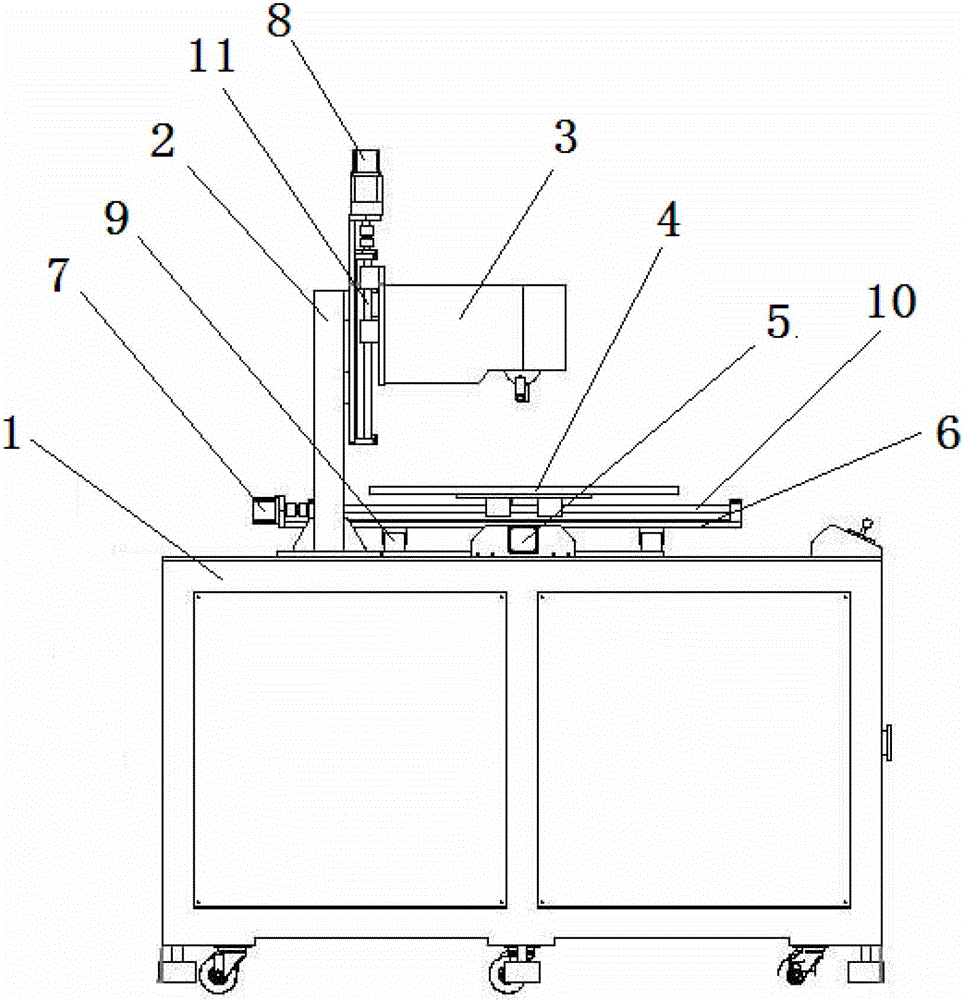

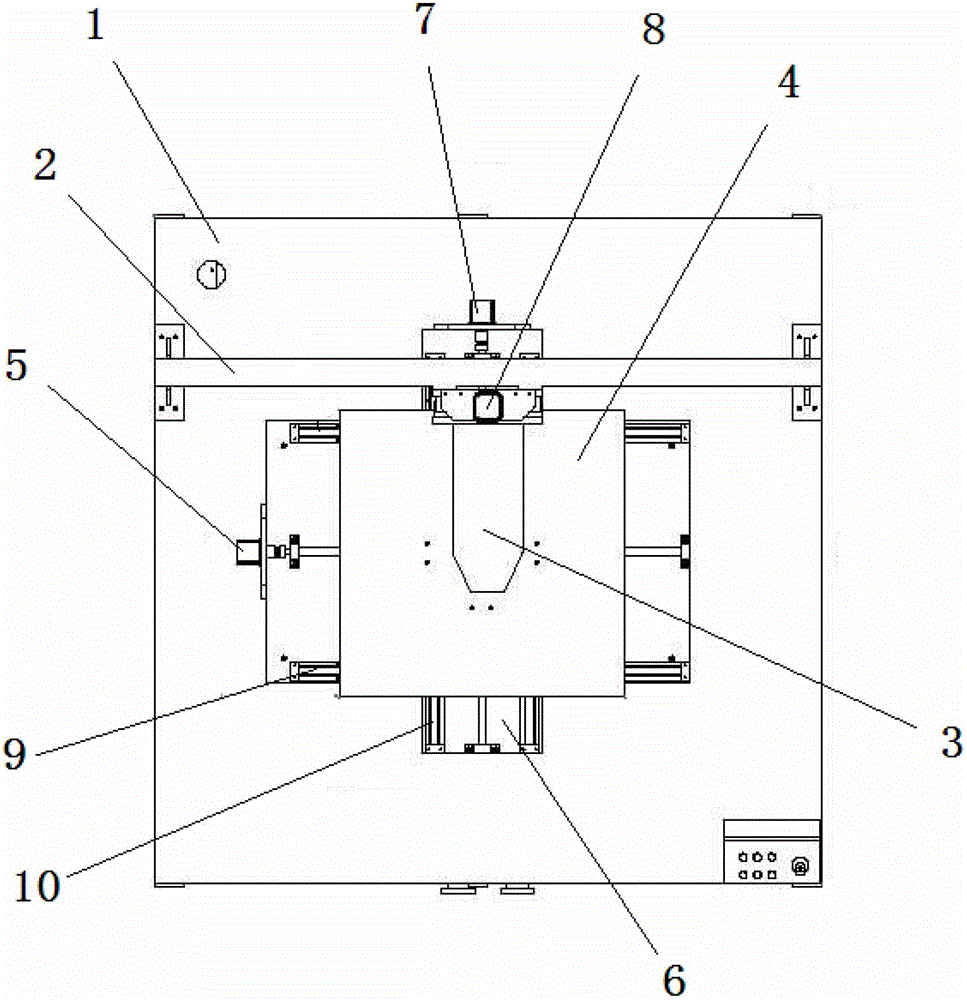

[0025] Example: Combined figure 1 , figure 2 and image 3 Shown is a specific implementation of the microscope device for PCB inspection provided by the present invention, which is mainly used for defect inspection of drilled PCBs. The microscope device for PCB detection consists of a working platform 1, a bracket 2, a CCD microscopic imaging lens 3, a PCB loading platform 4, an X-axis electric control screw transmission pair 5, a movable seat 6, a Y-axis electric control screw transmission pair 7, The Z-axis electronically controlled lead screw transmission pair 8, the X-axis linear guide rail 9, the Y-axis linear guide rail 10 and the Z-axis linear guide rail 11 are jointly composed.

[0026] A bracket 2 is fixed on the working platform 1, and the CCD microscopic imaging lens 3 is installed on the bracket 2 by means of a Z-axis electronically controlled screw drive pair 8, while the working platform 1 is equipped with an X-axis electronically controlled screw The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com