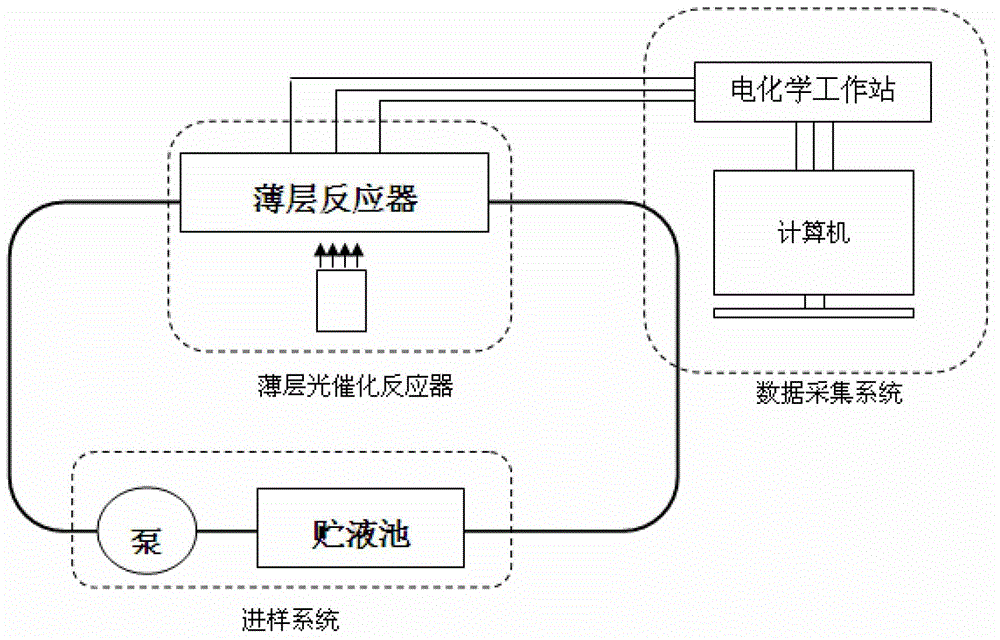

Circulating-type water chemical oxygen demand detection photoelectrochemical sensor

A chemical oxygen demand, photoelectrochemical technology, applied in the field of environmental analysis and sensors, nanomaterials, can solve the problems of slow speed, multi-corrosive and toxic substances sensitivity, low sensitivity, etc., achieve constant volume, high sensitivity, avoid photocurrent Effects of Response Error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

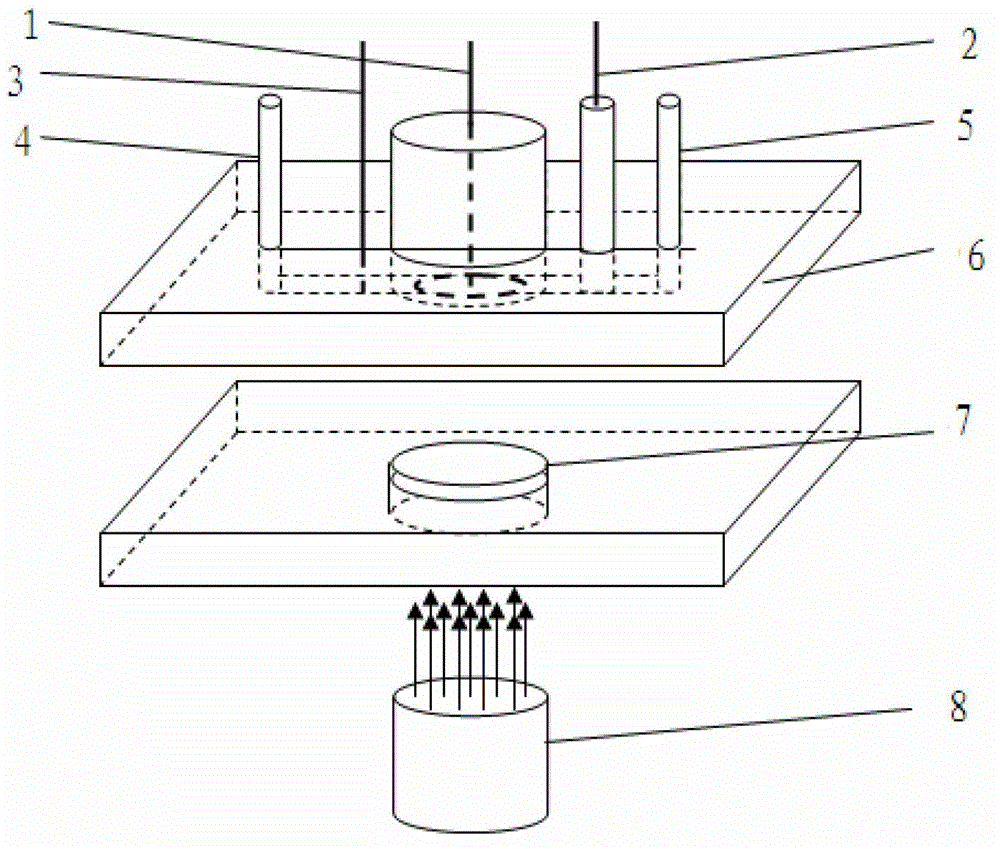

Method used

Image

Examples

Embodiment 1

[0034] TiO 2 The nanotube array was prepared by anodic oxidation method, the electrolyte was ethylene glycol solution containing 0.3mol / L HF, the voltage was 100V, and the time was 6h. Oxidized TiO2 The nanotube array is crystallized by heat treatment at 500° C. for 2 hours.

[0035] Connect the various parts of the photoelectrochemical sensor as shown in the attached figure, set the flow rate of the peristaltic pump to 10mL / min, apply a bias voltage of 0.2V in the constant potential mode of the electrochemical workstation, and set the power of the ultraviolet light source to 10% (120mW / cm 2 ), the support solution is 0.05mol / L phosphate buffer (Na 2 HPO 4 and NaH 2 PO 4 mix, pH 7).

[0036] Using photoelectrochemical sensor for glucose detection, the detection sensitivity is 66.6μA / mM (COD0.3469uA / mgL -1 ), the limit of detection is 0.0089mM (COD 1.709mgL -1 ).

Embodiment 2

[0038] The implementation method of this embodiment is the same as that of Embodiment 1, except that the bias voltage applied in the potentiostatic mode of the electrochemical workstation is 0.4V.

[0039] The detection of glucose by photoelectrochemical sensor has a detection sensitivity of 64.2μA / mM (COD0.3344uA / mgL -1 ), the limit of detection is 0.0093mM (COD 1.776mgL -1 ).

Embodiment 3

[0041] The implementation method of this embodiment is the same as that of Embodiment 1, except that the bias voltage applied in the potentiostatic mode of the electrochemical workstation is 0.6V.

[0042] Using photoelectrochemical sensor to detect glucose, the detection sensitivity is 48.4μA / mM (COD0.2521uA / mgL -1 ), the limit of detection is 0.0123mM (COD 2.356mgL -1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com