Parallel type water rocket launcher

A technology for launching devices and water rockets, which is applied to educational appliances, instruments, teaching models, etc., can solve the problems of model rockets polluting the environment, the parent body of multiple parallel sub-rockets without a matching launch device, etc., so as to achieve convenience and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

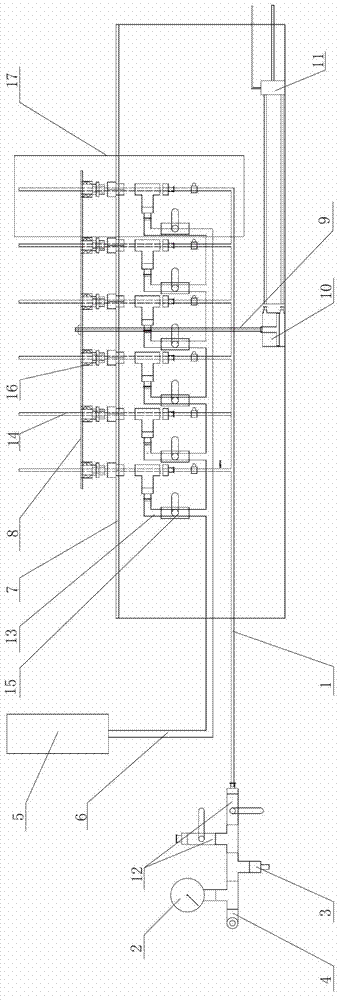

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, the launch device of this embodiment includes an inflation pipeline 1, an air pressure gauge 2, an air needle 3, an air pressure adjustment valve 4, a water injection device 5, a first connecting pipe 6, a launch platform 7, a launch plate 8, and a lead screw 9. Cylinder 10, intake pipeline 14, two first ball valves 12 and a plurality of second connecting pipes 13, the side wall of the inflation pipeline 1 is respectively connected with the air pressure valve 4, air pressure gauge 2, air needle 3 and two The first ball valve 12 is communicated, and one end of the inflation pipeline 1 is communicated with the intake pipe 14 of a plurality of water rocket launchers 17, and the water injection device 5 is communicated with an end of the first connecting pipe 6 respectively, and the first connecting pipe 6 is respectively connected with multiple One end of each second connecting pipe 13 communicate...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 To describe this embodiment, the launching device of this embodiment further includes a solenoid valve 11 , and the movement of the guide rod of the cylinder 10 is realized by turning on and off the solenoid valve 11 . The up-and-down movement of the guide rod of the cylinder 10 is realized by turning on and off the power of the solenoid valve 11. When the power is turned on, the guide rod of the cylinder 10 moves downward, and the launch plate 8 also moves downward, and simultaneously presses the launch sleeve 16 to play a role in each sub-section. The body water rockets are launched at the same time, so that the parent water rocket can be launched smoothly, and finally the parallel launch of the water rockets is realized. Other implementation manners are the same as the specific implementation manner 1.

[0011] Working principle: install each sub-body water rocket of the parent water rocket into the launch sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com