Bus duct

A busway and conductor technology, applied in the field of busway, can solve the problems that affect the operation safety and service life of the product, the shape and size are difficult to control, the temperature rise of the conductor 20, etc., and achieve high assembly efficiency, long service life and thorough emptying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below:

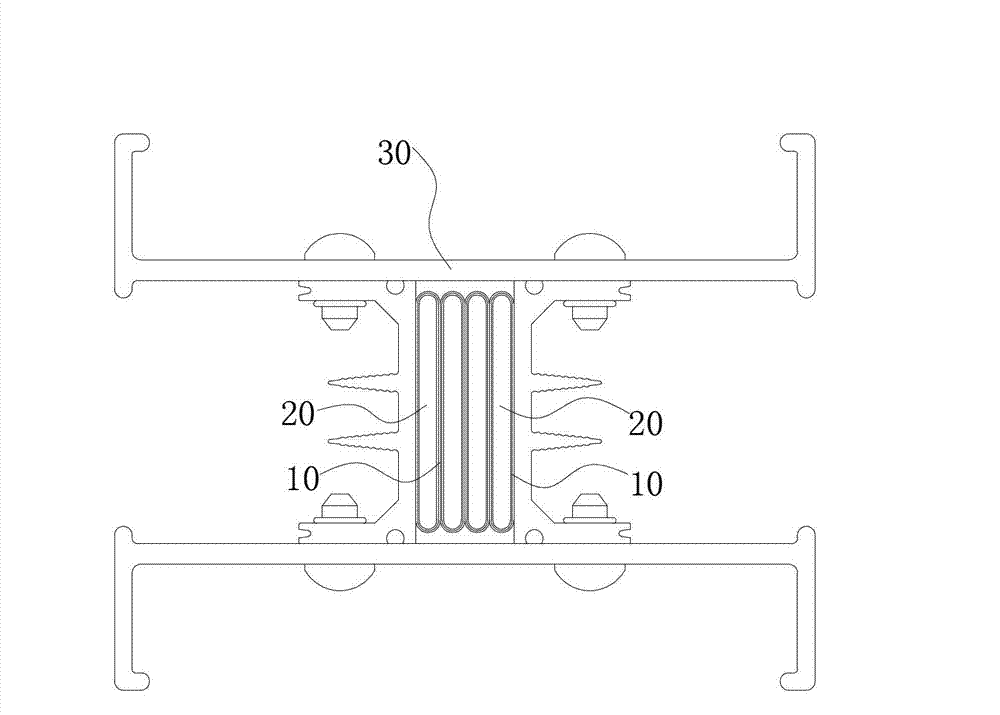

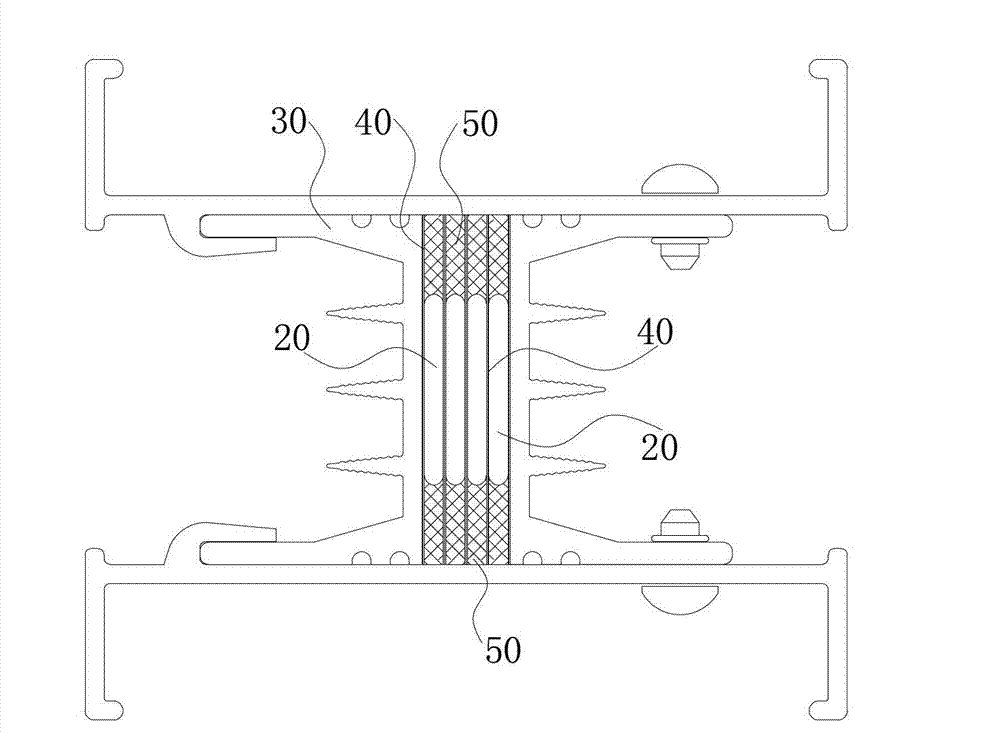

[0024] Such as image 3 , Figure 4 As shown, a busway includes a housing 30, a placement cavity is formed in the housing 30, and a plurality of conductors 20 are arranged in parallel in the placement cavity, and insulating strips 50 are respectively arranged on both sides of each conductor 20, and on the sides of the conductors 20 A planar insulating film 40 is provided on the two opposite surfaces, and the insulating film 40 simultaneously separates two adjacent conductors 20 and two adjacent insulating strips 50 .

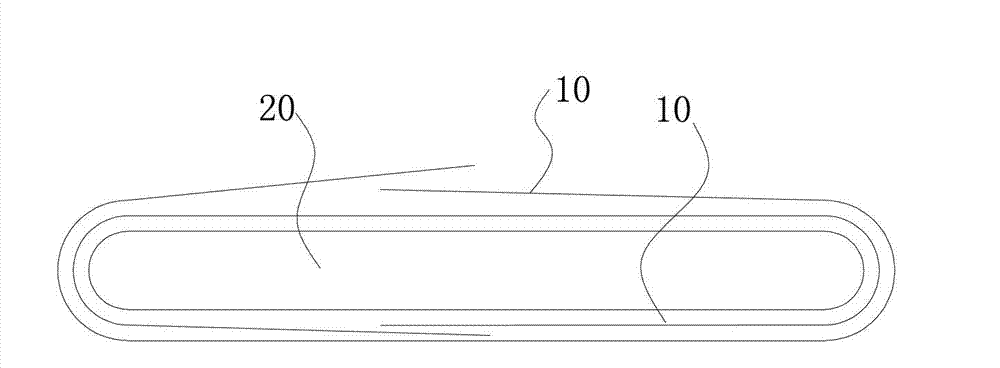

[0025] Wherein, the housing 30 includes two cover plates, and the two sides of the insulating film 40 extend to the inner sides of the two cover plates. Both sides of the conductor 20 are in the shape of a convex arc, the side of the insulating strip 50 close to the conductor 20 is in a concave arc 52 and matches the shape of the conductor 20, and the other side is provided with a gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com